| May 6, 2013 - 3:53 AM | Forum: Suspension/Handling/Braking · Post Preview: #1010228 · Replies: 7 · Views: 1,502 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Have a read through this: http://www.6gc.net/forums/index.php?showtopic=88153&hl= A post i made when i was making my front 3-pt strut bar. When you read it you will see square tubing will deflect the least. And when your mocking it up, rub chalk all over the bar then close your bonnet. If theres chalk on the underside of the bonnet, fix the positioning before you weld it(i made that mistake lol). |

| Mar 19, 2013 - 6:29 PM | Forum: Suspension/Handling/Braking · Post Preview: #1005563 · Replies: 23 · Views: 2,856 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

All Australian models came with the full sized spare and raised carpet too |

| Mar 3, 2013 - 4:54 AM | Forum: Engine/Transmission/Maintenance · Post Preview: #1003839 · Replies: 4 · Views: 851 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

I know that under the 5sfe throttle body there are 3 hoses, 2 of them have coolant in them and the third is a vacuum hose. One of those hose clamps probably got knocked loose IF the 3sgte throttle body is the same as the 5sfe. |

| Feb 6, 2013 - 6:08 PM | Forum: Engine/Transmission/Maintenance · Post Preview: #1001655 · Replies: 2 · Views: 550 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Definately not gonna use that engine, heaps of much newer 1MZ's in the yard. Would only take the transmission from that car |

| Feb 5, 2013 - 7:07 PM | Forum: Engine/Transmission/Maintenance · Post Preview: #1001546 · Replies: 2 · Views: 550 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Hey guys, After 1 too many track days my S54 has decided it wants to grind into gears then pop back out once in so its time for a new box. I've managed to find what I believe is an E153 from a 1996 V6 Camry in a wreckers yard for $116 if I go pull the thing out. http://www.picknpayless.com.au/eziparts/Di...%20Camry%20SK10 For now its just going to be used with the 5sfe until I can afford to replace that with a V6. I know its not going to be great with the 5sfe but it will always keep in my mind that a V6 should be in there instead. Now the details i'm unsure of with changing to the E153 are... 1. Can the Camry axles be used or does it need to be the MR2 inner/ST185 outter combo? 2. Will I be able to use the Camry shifter linkage or will i need the ST205? 3. Will I be able to use the Camry motor mounts? or once again does it need to be the ST205 mounts? 4. Will I need to change the carrier bracket? 5. Is there anything i'm missing or overlooking? Ok now for the other part of the question to the V6 owners out there, since there is a complete camry V6 in the wreckers yard and I do plan to swap in a V6 down the track... 1. Do you guys know if the Camry timing cover side mount will work in the celica? because it will most likely be pretty cheap and it could save fabrication of one 2. I plan to swap a VVTI 1MZ in, is it worth grabbing the ECU out of the 1996 since its a M/T ECU or should I just use a VVTI auto ecu? Thanks |

| Nov 23, 2012 - 11:24 PM | Forum: Suspension/Handling/Braking · Post Preview: #995030 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Have you used Abaqus before? Is that the simulation environment inside Solidworks? if so only once, I mainly use ANSYS interesting, i would run it again with a straight bar, I think the bend would cause more deflection than a shorter straight bar. Just a guess, I have no software to test this, but I have been making parts on cnc mills for 20 years, so understanding rigidity is something I have tried a time or 2. afaik the bend seen in some bars is a clearance thing for top mount IC, I doubt it is adding any rigidity. Bicycle frames and forks are a good example of rigidity in action, the materials used have a lot to do with it also. Chrome moly should be a great strut bar material imo. A straight bar will withstand ALOT more force than a bent bar of any sort. This is due to a buckling situation that we encounter as both sides are in compression and fixed. Doing the calculation for the flat bar I used I found that it will take a compression force of 8909.29 N at each end to cause the bar to begin to bend. The other reason that a bend is necessary is due to things getting in the way like, air intake piping, bonnet supports, throttle cable. So really it becomes impractical unfortunately. flat should be fine...  i would add the little triangles at the end of mine If that's the J-speed one, that's what modeled mine off, I just couldn't be bothered to make the triangles haha If my thesis supervisor is feeling nice after Christmas i might even try to persuade him to let me hook some strain gauges up to it and then we can get a pretty good idea of what kind of forces are being put on the bar. |

| Nov 23, 2012 - 8:12 PM | Forum: Suspension/Handling/Braking · Post Preview: #995019 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Ok guys, since i'm studying mechanical engineering at uni i have access to simulation software and did a quick comparison between flatbar, square tube and circular tube for a 2 point bar. Here are the results and are as expected really, but i'm still not gonna change my design. The tests were run using a force of 5000N at each end of the bar putting it in compression. No idea what they are actually experiencing. This test is also a big simplification assuming that the bar is free to slide in the axis that it sits (parallel to the engine). So this wont actually be the deflections happening under your bonnet, just showing people the difference in the cross sections. The dimensions are: Flatbar - 32x8mm Round tube - Outside diameter 20mm, inside diameter 18mm Square tube - 20x20x2mm    |

| Nov 23, 2012 - 9:32 AM | Forum: Suspension/Handling/Braking · Post Preview: #994985 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Dont paint it, sand it and clear coat it, it will look like chrome or stainless depending on how much sanding you do I love the idea, but hate you for suggesting it haha coz its so much work The fab work looks pretty good, but as was stated before the flat bar is going to flex. Tube, even a thin aluminum tube like the cusco or trd is going to be more rigid than a steel flat bar. As far as the bends go, the rigidity in shape you might be gaining, you are losing with longer bar length. I am not trying to nit pick and props for making one, I just think with a little more rigid material you could make it a lot stronger and lighter. You might look at places like mcmastercarr for tubing ideas. Ye I was thinking that but as I had that lying around in the garage I thought why not, plus anything is better than that stock decorative item which does NOTHING! |

| Nov 23, 2012 - 1:45 AM | Forum: Suspension/Handling/Braking · Post Preview: #994967 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

And then 2-points became 3!!     Havent test driven it yet, going to give it a coat of paint first! |

| Nov 22, 2012 - 10:39 PM | Forum: Suspension/Handling/Braking · Post Preview: #994952 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Ye, had a look and didn't wanna do the hood spacers. I decided to grind off the welds and re-do it. You can see from the photos that i had to put it slightly more centered so it started lower to avoid hitting the bonnet bracing. Funny story now, I'm half under the car trying to measure it up nicely when my mum comes out and just says why dont you put chalk on the top of the bar then close the bonnet and see where it hits. I thought why not lets give it a go, so the process then became trial and error to find an angle that worked. To finish it off I lined the bar up with blueberries and closed the bonnet to see that none were getting squashed! moral to the story, get your mum to help more often haha. Anyhow here are the pics of the 2-pt so far and ill get onto making the other points soon!    And the main difference between last time:  YAY! lol Thanks again for the suggestions guys! |

| Nov 22, 2012 - 6:53 PM | Forum: Suspension/Handling/Braking · Post Preview: #994943 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

get a GT4 hood... Tha strut bar looks great!!!!!  what about cut and grind the welds and invert the bar so the u shaped goes down... instead of adding more welds... GT4 hood sadly isn't in the budget at the moment. Get rid of the bends and you'll be fine. I would also suggest to keep the stock strutbar for more rigidity A straight bar can't work as it hits a few things along the way and the bends also provide some extra rigidity That strut bar looks good! Are you able to start over? You could always grind the welds off, cut some of the ends off of the cross bar, make the bends slightly flatter, and reweld. As long as the weld is good, you won't lose any rigidity. Good luck getting it modified! Thats what i'm most likely going to have to do and I think is the most logical for a rigid bar. I was just hoping to avoid welding with it on the car again (im scared an electrical spike could kill something) What about if you turn it around so the crossbar is towards the back and re-drill the holes on the mounts? Will it still be in the way? There are other things in the way if its turned around like the intake plenum and theres not enough bonnet clearance to go above it. Add some hood spacers dude that's what I did it adds a hood cowl effect cooling the underhood temp. Never heard of them, anyone got pics? Thanks for the replies guys! keep them coming! |

| Nov 22, 2012 - 12:36 AM | Forum: Suspension/Handling/Braking · Post Preview: #994895 · Replies: 23 · Views: 4,033 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

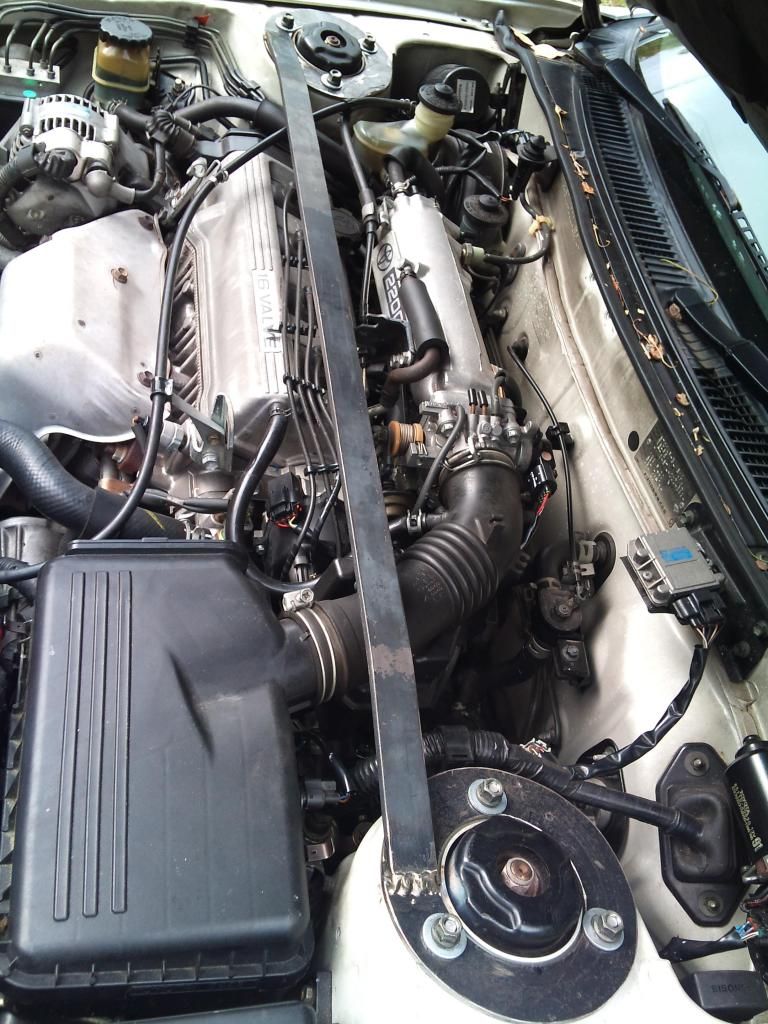

So made a strut bar today all fits perfectly, is beefy as all hell but then I decide to try and shut the bonnet..... When I was measuring it, I didnt notice the support bars running along the underside of the bonnet and of course with my luck they hit the strut bar preventing me from closing the bonnet So now I need some ideas from you guys on how to modify the strut bar without starting again. My favourite idea is cutting the bar in the middle and bashing the bends at either end down a little but and then re-welding it in the middle. My concern is strength when it is re-welded. OR I can grind off the welds at each end and make the bends a slightly lesser angle. Prefer not to do this one but if its the best option I guess I have no choice. If theres any other ideas you guys/gals can think of let me know or please critique mine just above. It is going to become a 3-pt bar just trying to sort two out first. Here are the pics:    |

| Nov 20, 2012 - 2:17 AM | Forum: Engine/Transmission/Maintenance · Post Preview: #994679 · Replies: 12 · Views: 3,119 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Are they the speed source ones? If so you can select the option for the 6gc. http://speed-source.net/?wpsc-product=toyo...n-base-bushings |

| Nov 18, 2012 - 2:20 AM | Forum: Suspension/Handling/Braking · Post Preview: #994350 · Replies: 20 · Views: 3,930 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Checked the thickness and all are within spec! Did the de-glazing about 2 weeks ago so here are the results: Glazed and greasy state(from my fingers):  Attacked with a cup brush on the angle grinder to remove glaze:  After doing that I tried two different methods to give them a nice finish 1. Sanding with coarse sand paper then getting finer  2. Sand with emery cloth in circular motion then go over them quickly again with the cup brush. Realised I don't have a picture of this but here the pic of the one above that i repaired by using the emery cloth and another quick go with the angle grinder.  Option 2 came out with a much better finish so I did the rest of them using that. Sorry for the crappy pics I only had my mobile phone handy. From the advice given I decided to just use the race pads all the time to save the hassle of changing them over all the time. Lastly the feel of the non-glazed rotors is amazing. I can't say ive driven on a brand new set of rotors or resurfaced rotors but these must come pretty close. So I am very happy with how they turned out and would recommend this method to anyone. It ended up taking about an hour/wheel. Thanks again guys for the advice, much appreciated! |

| Oct 30, 2012 - 11:26 PM | Forum: Suspension/Handling/Braking · Post Preview: #992528 · Replies: 3 · Views: 1,002 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Not talking from experience here, but from what i've heard the shocks will blow pretty quick on a 2" drop mainly if they bottom out alot on bumps. If your going for the warranty be sure to keep the stock springs and put them back on when you take them in (i'm assuming that lowering springs will void the warranty so they will want to see what you are using). To install the springs follow this: http://www.6gc.net/howto/install_coilovers_or_springs |

| Oct 30, 2012 - 1:58 AM | Forum: Off Topic · Post Preview: #992429 · Replies: 41 · Views: 19,817 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Couldn't agree more, very cheap and nasty inside. A friend of mine took delivery 3 weeks ago of the Toyota 86 and to his defense he hadn't driven the car for long but cornering in the 86 is no better than a 15 year old celica on stock suspension, we did a test at a track (yes surprisingly he agreed to track a 2 week old car lol) Of course i got monstered on the straight but through the corners my baby held its own |

| Oct 29, 2012 - 2:06 AM | Forum: Buying/Selling · Post Preview: #992319 · Replies: 24 · Views: 9,300 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

If you are willing to ship internationally and split up the dash, can you give me a price for the plastic shifter surround to Sydney Australia |

| Oct 29, 2012 - 2:05 AM | Forum: Buying/Selling · Post Preview: #992318 · Replies: 23 · Views: 2,685 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

If you still have the stuff and your willing to ship internationally, can you give me a price on the plastic that surrounds the shifter (providing it has all 4 tabs) to Sydney Australia |

| Oct 23, 2012 - 9:08 PM | Forum: Interior/Audio/Electrical/Wiring · Post Preview: #991838 · Replies: 1 · Views: 896 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Disclaimer: I CANNOT BE HELD RESPONSIBLE FOR ANYONE TRYING TO REPLICATE THE FOLLOWING AND CAUSING INJURY TO THEMSELVES OR OTHERS. THIS IS SIMPLY A ROUGH OUTLINE OF HOW I WENT ABOUT MAKING MY HARNESS BAR. CAUTION: If employing the use of a harness bar, in the event of a crash this is what keeps your steering wheel free of an imprint of your face. Do not cut corners! If you do not have the means or skill to complete the task seek professional assistance! Ok now we can get to the good bits! I've been racing the Celica a fair bit lately, and decided the stock seatbelts were throwing me around WAY too much so I would need a harness. I thought about doing a dodgy and bolting the shoulder straps to the floor but then wised up and decided to build a harness bar. Here is the final product:     And how it fits in the car:    Materials required: 2m of 2.6mm wall thickness 38mm diameter round tubing 2m of 1.6mm wall thickness 18mm diameter round tubing 300x300x5mm steel plate Building Steps Befriend someone who has a workshop with a pipe bender(want mandrel bent not crush!) or if you have the $$ buy one! Bend the 38mm diameter pipe so there are two 90 degree bends with a centre distance of 1160mm. Cut the bent bits off so they are 230mm in length. Using an angle grinder cut the steel plate into strips to be used for the brackets. I used 50mm x 130mm for the top and 50mm x 70mm for the base (because otherwise they will hit the seat) Bend the 50x130mm strips at 90 degrees in the middle and drill a 13mm hole in the centre of one of the halves. Bend the 50x70mm strips at 90 degrees 20mm from one end and drill a 13mm hole in the large part. Unbolt your existing seatbelts and let them hang there for the time being. Using the existing bolts, bolt the 50x130mm bracket in the top seat belt holes. Making sure that the 90 degree bend is facing the boot. Get the bent 38mm diameter tubing and place it in the car. Now this is where your going to need probably two friends to hold the thing so it can be tack welded. I would advise TIG welding so there is no sparks, or feel free to cover up the interior of the car very well and use MIG or stick. Now making sure the bar is flush with the two brackets and level, tack the bar in place. Once tacked, remove from the car and weld it up properly. Now bolt the 50x70mm brackets into the existing lower seatbelt mount positions leaving the 20mm part facing up. And place the welded cool! bar back into the car and bolt it on. Get into the drivers seat with your helmet on and set the seat into your driving position. Do not move the seat now! You want to angle the bar so that its at the same height as the top of your seat (want the shoulder straps to go straight back not down on an angle). Get the 18mm diameter tube now and place it 120mm away from the edge of the top bend and down onto the bottom bracket and tack weld them up. Remove the whole thing from the car and finish all welds up properly. Optional: If you want to reinforce it like i did in pictures 3 and 4 you will not be able to leave the bar in and the stock seatbelts in so when you go to the track you will need to unbolt the stock seatbelts and put in the bar. I just cable tie the seatbelts to the bar to stop them flapping around when in driving. I cant believe that this would be road legal so dont use it! Unfortunately i don't have any pictures of when i was building it coz we were in a hurry! But i will give you this pic, a guy in the car club owns a 672hp twin turbo 2JZ and tracks it! Photo is from the last Wakefield park track day  And my semi slick race tyres, lefts are 225 50R15 Toyo's for the front and the right ones are 205 55R15 Falkens for the rears:  If people want pictures of how i mounted the lap bents and crotch strap let me know! this is still my DD so nothing has been removed! The bar works very well and is sturdy as anything! Any questions, let me know! |

| Oct 23, 2012 - 6:40 PM | Forum: My Project · Post Preview: #991806 · Replies: 682 · Views: 179,018 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

| Oct 22, 2012 - 6:27 PM | Forum: My Project · Post Preview: #991651 · Replies: 219 · Views: 113,082 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

I've seen your 1MZ teardown thread, but is there one i missed about how you mated the 1mz heads to the 3mz block? or is it quite literally just swap them over? |

| Oct 20, 2012 - 3:40 AM | Forum: Suspension/Handling/Braking · Post Preview: #991363 · Replies: 20 · Views: 3,930 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Thanks, I'll have to measure mine now. Also still haven't gotten the time to try deglaze them but will report back when I have done so |

| Oct 19, 2012 - 7:41 AM | Forum: Suspension/Handling/Braking · Post Preview: #991284 · Replies: 20 · Views: 3,930 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

[/quote] How so? I thought you were referring to breaking in pads by getting a thin film of pad on the surface of the rotor which, if you only use pads "A" with rotors "A" and pads "B" with rotors "B" you won't need to do this everytime because the pads will already be broken in for the rotors you're using. [/quote] I thought this also. @celica74 if you have the rotor specs lying around that would be awesome! |

| Oct 17, 2012 - 4:22 AM | Forum: Engine/Transmission/Maintenance · Post Preview: #991129 · Replies: 5 · Views: 1,071 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

Have you pulled out the IACV and cleaned it? Its very prone to carbon build up and makes the car idle like crap when it does so. Basically pull off the throttle body and its underneath (assuming you have a 5sfe, not sure about 7afe). There's 4 brass screws holding it on which will be near impossible to get off without stripping so try use an impact screwdriver to get them off. Then use almost a full spray can of throttle body cleaner to get every last bit of carbon out and of course clean the TB since you have it out. Replace the gasket on the IACV and put it all back together. |

| Oct 16, 2012 - 7:04 PM | Forum: Suspension/Handling/Braking · Post Preview: #991068 · Replies: 21 · Views: 3,062 |

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline |

http://www.6gc.net/forums/index.php?showto...t=0&start=0 Yellowchinaman makes them custom for our cars |

New Replies New Replies No New Replies No New Replies Hot Topic (New) Hot Topic (New) Hot Topic (No New) Hot Topic (No New) |

Poll (New) Poll (New) Poll (No New) Poll (No New) Locked Topic Locked Topic Moved Topic Moved Topic |

| Lo-Fi Version | Time is now: November 25th, 2024 - 10:50 PM |