|

Oct 19, 2014 - 6:25 AM Oct 19, 2014 - 6:25 AM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

I have to do the head gasket and when I'm in there I am shaving the head, a port polish, apexi neo AFR, wideband O2 sensor and delta cams. The car currently has a CAI and 4-1 ebay headers plus a hollow cat and a DC sport muffler.

out of curiosity what would the affect of having a TB on either end of the intake Manifold have? -------------------- |

Oct 19, 2014 - 11:09 AM Oct 19, 2014 - 11:09 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

Having one TB at each end or just switching ends? Switching ends wouldn't really have any affect I'm aware of, I'm not sure about having one at each end with one plenum, you'd probably want to have the plenum split in the middle to make effectively two tuned intakes. You'd get more even air distribution I'd imagine.

With those mods, yes a custom built intake will make a difference, just look up some of the math involved and figure the right plenum volume, runner volume, and runner length to hopefully hit your target RPM. I was assuming this was going on a bone stock 5S, my bad. -------------------- |

Oct 19, 2014 - 3:52 PM Oct 19, 2014 - 3:52 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

Splitting them up would be pretty sick! Sky's the limit...

-------------------- |

Oct 19, 2014 - 3:57 PM Oct 19, 2014 - 3:57 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

I've even seen race engines with unequal length velocity stacks (ITB) to spread out the engine's power peak, assuming the exhaust runners are all equal length. Velocity stacks need to be matched to the cylinder exhaust runner length if the exhaust runners are not all equal length. It's not as simple as it all sounds, you can get quite nit picky technical and doing so usually nets the best power gains.

-------------------- |

Oct 19, 2014 - 4:24 PM Oct 19, 2014 - 4:24 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

I just want better gains I'm not out to win a tittle or anything.

-------------------- |

Oct 19, 2014 - 4:34 PM Oct 19, 2014 - 4:34 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

Best gains come from proper design.

-------------------- |

Oct 19, 2014 - 5:18 PM Oct 19, 2014 - 5:18 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

Obviously.

-------------------- |

Oct 19, 2014 - 5:27 PM Oct 19, 2014 - 5:27 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

Yes, so no sense just hacking some stuff together and spending all the time to make it and get it leak free to find out you screwed up the plenum volume or runner length or both and have actually lost power. The stock 5S runners are very narrow, I know it's a pain but see about getting some mandrel bent aluminum tube or something and making fatter runners, ideally you want them to taper to the cylinders to compress the air column some so it 'pops' into the chamber when the valve opens and has a good turbulence and swirl to mix the A/F thoroughly for complete combustion and knock resistance.

Funny thing is, I don't even do this stuff or build this stuff, I've just learned this reading way too much and researching about things that interest me. If you do this right you can bolt on some nice gains with the rest of the porting and cams and see some good flow numbers. Remember to leave about a 1mm anti reversion lip on the bottom of the exhaust ports. QUOTE Anti-reversion Headers In our page on cylinder head porting, Henry (aka Double H) explains that the primary pipes in the exhaust manifold should at match the exhaust port diameter on the cylinder head; but to reduce reversion, a primary pipe that is slightly larger than the exhaust port is better. Reversion is the flow of exhaust gasses back into the combustion chamber when the downward movement of the piston creates a vacuum in the cylinder. As we mentioned in engine tuning basics, the exhaust valves are still open when the intake stroke begins. This presents the potential for exhaust gasses to be drawn back into the combustion chamber when the piston moves down the cylinder. Any exhaust gases that are drawn into the combustion chamber will displace the air/fuel mixture being drawn in through the intakes valves and will increase the temperature in the combustion chamber, thus reducing the volumetric efficiency of the engine, as well as engine power. Preventing reversion will reduce the contamination of the air/fuel mixture by the spent exhaust gasses and will improve the efficiency of the engine. An anti-reversion header or AR header that is specifically designed to inhibit reversion would be your best choice. Anti-reversion headers have a built-in lip that restricts exhaust gas flow back into the combustion chamber. http://www.custom-car.us/exhaust/header.aspx quick dirty explanation of things. -------------------- |

Oct 19, 2014 - 6:50 PM Oct 19, 2014 - 6:50 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

yes but isn't the the intake flange the same width as the intake ports on the head?

-------------------- |

Oct 19, 2014 - 7:09 PM Oct 19, 2014 - 7:09 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

The ports in the head and the ports on the manifold probably match somewhat closely on the intake, but you may be surprised when you lay the gasket over both to see that the metal overlaps the gasket noticeably. I port matched the exhaust manifold on my 2ZZ to the exhaust gasket which left an anti-reversion lip all the way around the port on the head (I didn't touch the head). The 2ZZ in stock trim is a fairly healthy breather, even without anything gasket matched. The 5S is likely similar on the intake and exhaust. My 7A exhaust ports eclipsed the gasket a fair amount as well...easier to cast things a little small I guess.

If you're hogging out the ports in the head, go as big as the gasket openings then port the runners to match, however cast runners like that are very rough inside and there are often 'nodules' of aluminum sticking up and areas of severe roughness that hurt flow more than you think. You should get a flexible shaft and some flap wheels and get up in there and smooth it and hog it out some. -------------------- |

Nov 14, 2014 - 8:58 PM Nov 14, 2014 - 8:58 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

Thats not a bad idea. I don't plan on changing the intake runners but i will polish them from the inside. Here is a picture of the TB I picked up a few weeks ago.

It's off a V6 camry. I cleaned it up a bit. Its quite bigger than the 5sfe TB about 10mm

-------------------- |

Jan 29, 2015 - 9:24 PM Jan 29, 2015 - 9:24 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

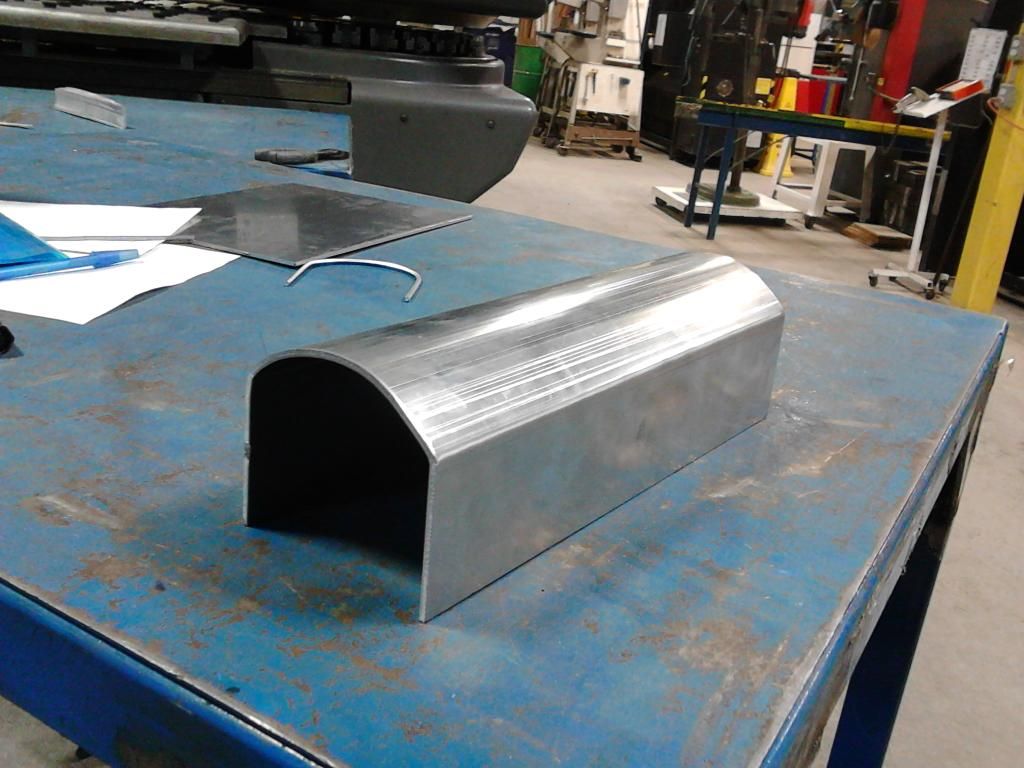

Finally starting the intake. Got the runner cutouts right. Formed the two sides. Now to weld on the runners and close off the intake and make a TB flange!

-------------------- |

Jan 30, 2015 - 8:24 PM Jan 30, 2015 - 8:24 PM

|

|

Enthusiast      Joined Jan 4, '12 From US Currently Offline Reputation: 6 (100%) |

How much plenum volume are you going to have/chose to have?

-------------------- 1993 Celica GT Coupe - sold

1994 Celica GT Liftback |

Jan 31, 2015 - 6:37 PM Jan 31, 2015 - 6:37 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

I think I'm changeling the design. What's the formula for calculating plenum volume?

It's shouldn't be bigger 1.5 times than displacement. Right? -------------------- |

Jan 31, 2015 - 6:51 PM Jan 31, 2015 - 6:51 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

It depends.

http://www.fsae.com/forums/showthread.php?...er-Calculations This touches on some of the complexities, runner length/diameter/taper as well as cam specs, play a role in plenum volume. This simplifies it some. http://speedtalk.com/forum/viewtopic.php?t=1142 https://www.physicsforums.com/threads/plenu...-design.376326/ This has some good general design tips. This post has been edited by Bitter: Jan 31, 2015 - 6:55 PM -------------------- |

Feb 12, 2015 - 5:29 PM Feb 12, 2015 - 5:29 PM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

-------------------- |

Feb 12, 2015 - 9:49 PM Feb 12, 2015 - 9:49 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

Looking good, the first one you posted looked way too large.

-------------------- |

Mar 8, 2015 - 8:00 AM Mar 8, 2015 - 8:00 AM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

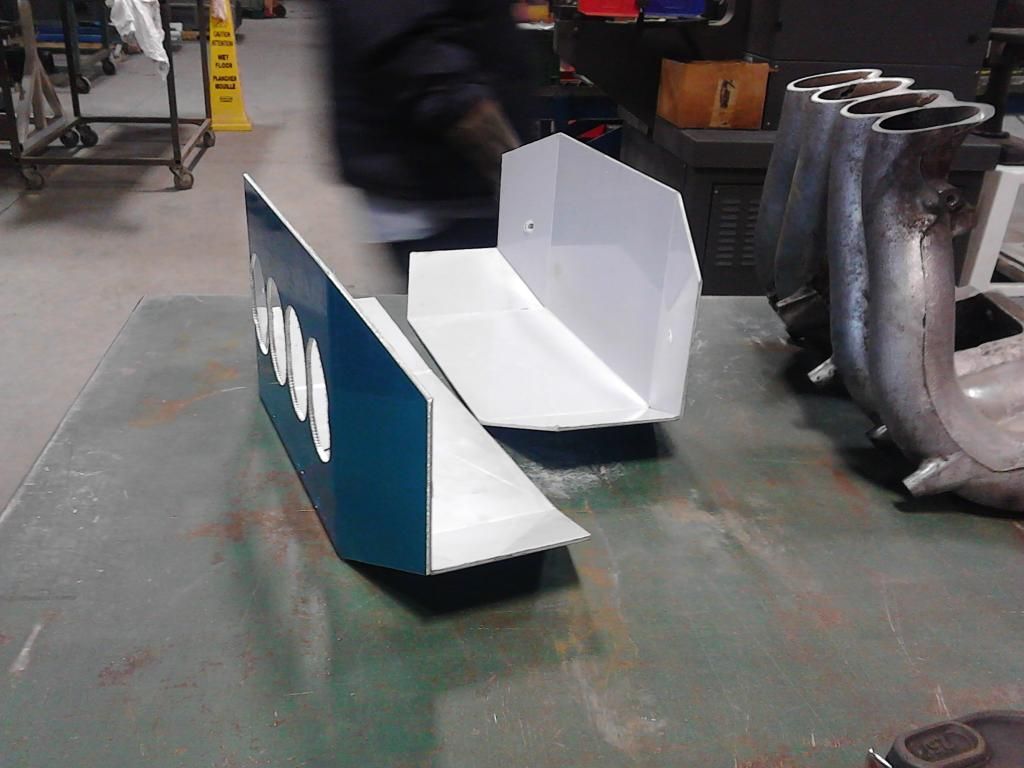

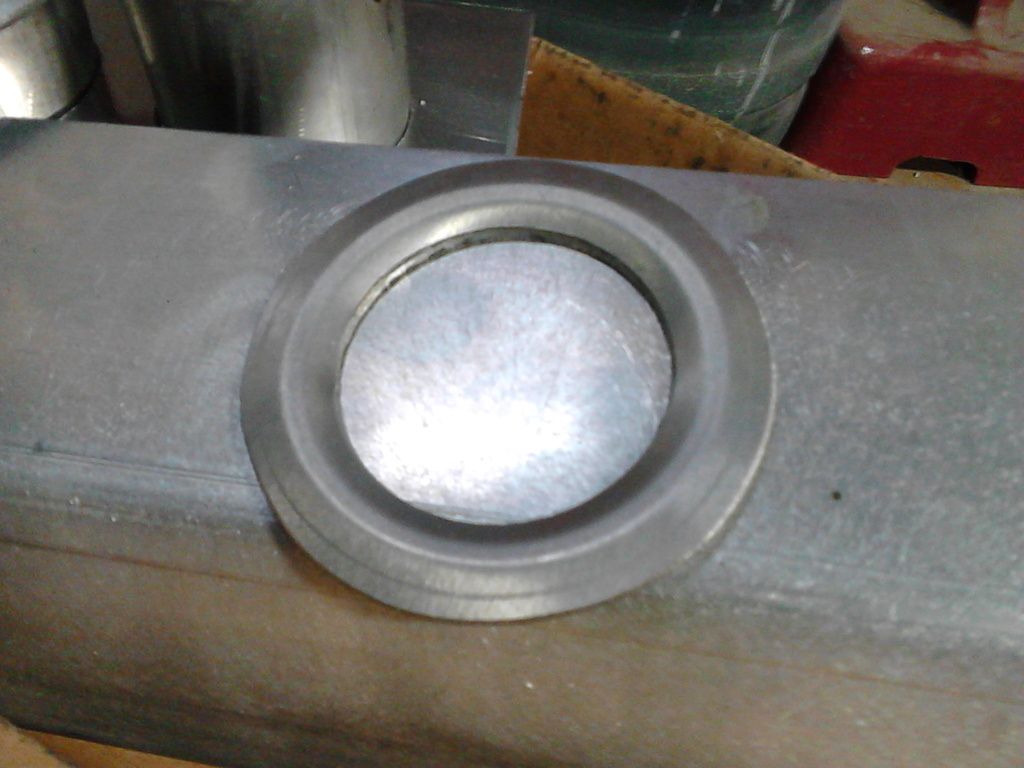

I have decided to use custom runners instead of the hacked manifold... Just got the pipe bent last week.. putting some finishing touches on the runners..

using the flateners and the Amada press break to oval out the ends of the 2" pipe to match up with the flange..     This is a piece of pipe that broke when they were bending it.. Im using it for a setup piece and I'm glad I have it now.. I might have to bore out the flange a bit. what do you think?? any input will be appreciated.  I made some velocity stacks at work.. well kind of.. Ill post some picks later of the stacks once there finished.. I would like some input on the stacks once there up. -------------------- |

Mar 8, 2015 - 8:48 AM Mar 8, 2015 - 8:48 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

It's looking much better, sorry I can't offer any actual insight other than 'that looks like it'll work better' since I'm not well versed in the intricacies of manifold design but know enough to look at an engine and manifold and have a fairly good idea what may not work well.

-------------------- |

Mar 28, 2015 - 7:44 AM Mar 28, 2015 - 7:44 AM

|

|

|

Enthusiast   Joined Jun 21, '14 From Ottawa, Ontario, Canada Currently Offline Reputation: 0 (0%) |

Here is a couple photos of the velocity stacks (kind of) I made. I'm getting a new manifold flange made of 0.500 t6 with bigger ports. Should be finished in a week or so.

-------------------- |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 22nd, 2024 - 7:24 AM |