|

May 25, 2008 - 10:39 AM May 25, 2008 - 10:39 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

Having done over 9 months of research into charge cooler designs I have decided to make my own. Not as difficult as you may think as the charge cooler design is pretty simple....basically a box with a radiator in it. There has been loads of debate throughout several forums as to which is the best method for things like waterflow direction ... placement of filler caps etc etc the list goes on and on...all I can say is that Toyota didnít get it wrong...they just didnít get it right enough....I know why they came up with the design that they did...it wasnít choice..it was lack of choice...cost savings and motorsport restrictions at the time. I could go into deep descriptions as to why the water flows the way it does ...I have yet to prove that its the wrong way or the right way...but with some help from the technical bods from the GT4 owners club I should soon have an answer...although changing flow direction is a simple job...just a matter of swapping two hoses around...no biggy.

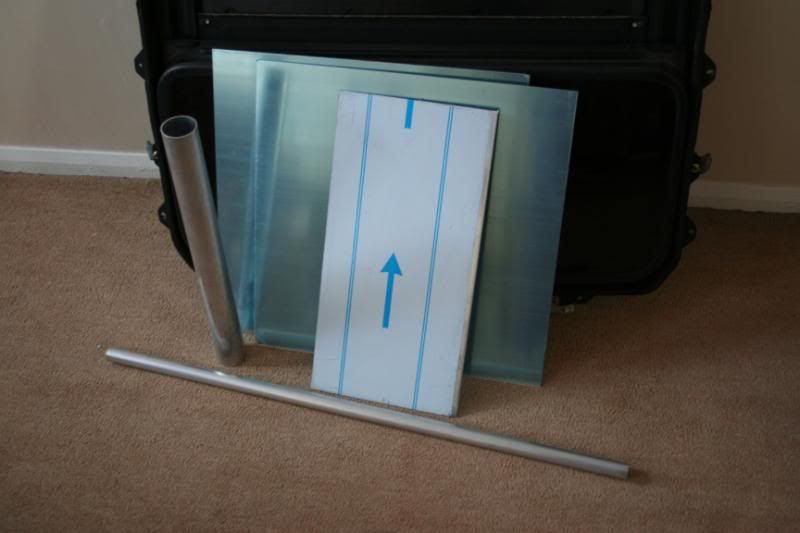

Day one Obviously the first step is to come up with a design which I have done over the past nine months...hopefully it will be worth it. I wonít bore you with technical specifications, you`ll see what it looks like from the photographs. Next up was to source some material, and after ten minutes with Google I discovered a place called UK aluminium who have managed to supply me all but one of the pieces of alloy that I wanted...funnily enough I got the hardest to find piece from Motorworld (a local cheap car parts shop) in the chav section. For my design I required Ė appologese to you guys over the pond as you work in inches dont you 3mm is roughly 1/8 inch (1 inch = 25.5mm) 2x 500mm/500mm/3mm sheets. 1x 250mm/500mm/3mm sheet 1x 25mmOD/1000mm tube 1.59mm wall thickness (16 gauge IIRC) 1x 70mmOD/500mm tube 1.59mm wall thickness 2x 390mm/100mm/100mm charge cooler specific radiator core (with extra dense fin arrangement and extra galleries)  So let the work begin...I have managed to control myself and not rush into it headstrong and fluff it up...patience is the key...lots of it. I started off by designing a simple header tank which could also double as a swirl pot with minor modifications.....be award though that if you want to attempt this yourself...you are limited to a 100mm tall charge cooler, as if you go taller than this (there is room) you will not be able to fit a header tank at there are only one or two place it can fit, and both positions have limited head room due to the bonnet framework....I have decided to put mine where the current charge cooler overflow fits and reposition that elsewhere. Right.....back to the header tank production...itís only small and loosely based on the TTE version. I started off with some 70mm alloy tube...cut it to length...you can make it pretty much any length as there is plenty of space downwards.  Here is the 70mm tube cut to length with the first of the inlet outlet holes marked up....that one happens to be the inlet. My next train of thought was to start one of the more difficult tasks first...and that was to cut the inlet pipe in such a way that it matched the curve of the header tank....an easy task with a CNC machine or power tools, but I am making this entirely by hand using some of my granddads tools....a bit of a promise that I made to myself. The task is slightly more time consuming but the results thus far have been good. I marked up the 25mm pipe and started to hacksaw away......I got the shape 80% there...I then rapped a spare piece of 70mm pipe in wet n dry and used it as shaping tool. After over an hour of sanding it is a near perfect fit and actually forms a perfect seal between the two pipes.  This pipe will eventually be cut shorter, but I left on a little extra to hold onto during welding  I then cut the inlet pipe to length and marked the corresponding hole onto the 70mm pipe ready for working away with a hand drill and a needle file. Which I will be doing as soon as I have posted this up.  I will then cut a second Outlet pipe (sigh another hour of sanding) and cut a second hole in the 70mm pipe. This will be an ongoing blog type thing which will continue until the charge cooler is up and running...hopefully within two to three weeks. Day Two...nothing much to report No pictures I`m afraid......drilled and shaped the holes into the headertank/swirl pot hybrid and cut and shaped the second inlet pipe...well..... outlet pipe in this case. Thats about it...the hours of sanding and shaping have been a little painstaking but are complete. Day five - ish Spent an amusing two hours filing away at some alloy sheet whilst watching the Monaco grand prix...both inlet and outlet for the header tank swirl pot hybrid have been completed....the end caps have been cut out...what an irritating process that was...cutting circles from alloy by hand is not easy, so alot of filing has been needed....a smaller hole was cut into the lid to enable fitting of the rad cap neck...I`m afraid I had to go with an electric drill with this as trying to use a 30mm hole cutter to cut a hole in 6mm sheet alloy was....well lets say I almost broke my wrists trying to do it. Needless to say working with alloy has been pretty easy so far...I `m looking forward to the arrival of the cores so I can match them perfectly to the casing and start the serious side of the manufacture. Just one question for anyone that knows about aluminium fabrication....is it required to put little castleations (sp) along the edges of the joining surfaces to allow the weld to penetrate into the joints???? Anyway...here is the header tanks as it stands....excuse the tape holding it together.....it needs finishing and polishing but i`m not going to do that until its all welded up.  |

May 26, 2008 - 1:36 AM May 26, 2008 - 1:36 AM

|

|

|

Enthusiast   Joined Sep 13, '06 From St. paul, MN Currently Offline Reputation: 10 (100%) |

Nice work so far! very interested, please update...

--------------------  |

May 26, 2008 - 2:01 AM May 26, 2008 - 2:01 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

cheers...I will keep updating it...but I have to wait now for my custom radiator cores to arrive...hopefully it will be tuesday.

|

May 26, 2008 - 8:55 AM May 26, 2008 - 8:55 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

great work so far!

-------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

May 27, 2008 - 9:43 AM May 27, 2008 - 9:43 AM

|

|

|

Enthusiast      Joined Dec 19, '07 From tx Currently Offline Reputation: 22 (100%) |

Just one question for anyone that knows about aluminium fabrication....is it required to put little castleations (sp) along the edges of the joining surfaces to allow the weld to penetrate into the joints???? Amazing work - sometimes the best results def come from working the material by hand or with simple power tools. As for the above question - no you don't have to make small cuts on the mating surfaces [I think that's what you mean?] to get them to seal better. I've done this before with MIG welding on carbon steel but in this case I assume you will be having the peice TIG welded and all should seal nicely if the surfaces are well mated [IE no gaps etc to be filled]. I know what you're thinking in this but IMO it would probably just make it more difficult. If it were me I'd get with whoever was actually going to be doing the welding and see what they think will provide them the best chance at creating a pressure holding seal. If it were me doing the welding I'd want the mating surfaces to match as best as possible with no gaps to be filled etc. Hope this helps - sorry I have a hard time explaining this kind of thing. --------------------  ENGINE: '93 RC 3S-GTE/WRC CT-20b [18-20PSI] PERF: TRD/HKS/ARP/NGK/MSD/ACT/Blitz/STRI/APEX'i/TwosRus/GReddy/Magnaflo/KOYO SUSP: Tein/Bilstein/SusTech/ INT: SS-III SEATS/Toyota Hyper Sports EXT: WRC/TRD/404 Its a safety feature so that people like you don't end up killing themselves or everyone around them. Slow down Paul Walker. 6GC Chat - Go there: [url="http://www.griffgirl.com/forum/chat/index.php[/url] |

May 27, 2008 - 11:22 AM May 27, 2008 - 11:22 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

Just one question for anyone that knows about aluminium fabrication....is it required to put little castleations (sp) along the edges of the joining surfaces to allow the weld to penetrate into the joints???? Amazing work - sometimes the best results def come from working the material by hand or with simple power tools. As for the above question - no you don't have to make small cuts on the mating surfaces [I think that's what you mean?] to get them to seal better. I've done this before with MIG welding on carbon steel but in this case I assume you will be having the peice TIG welded and all should seal nicely if the surfaces are well mated [IE no gaps etc to be filled]. I know what you're thinking in this but IMO it would probably just make it more difficult. If it were me I'd get with whoever was actually going to be doing the welding and see what they think will provide them the best chance at creating a pressure holding seal. If it were me doing the welding I'd want the mating surfaces to match as best as possible with no gaps to be filled etc. Hope this helps - sorry I have a hard time explaining this kind of thing. Fully understood...thanks A quick question to the mods...how do I get my user name changed??? or is it just a matter of forgetting this user name and signing up with a new one??? My insanity has been cured so I`d like to go with my real name...cheers Nial This post has been edited by Insanity-74: May 27, 2008 - 11:25 AM |

Jun 4, 2008 - 10:48 AM Jun 4, 2008 - 10:48 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

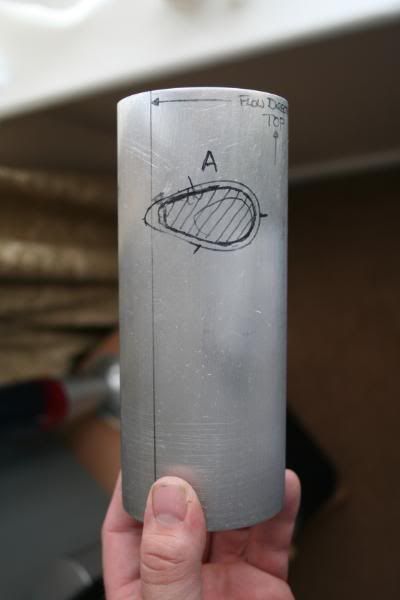

Well the Core has finally arrived...size is exactly correct...its a shame there are 3 main galleries instead of 4 or 2, but apparently its OK to intersect a core half way across as each gallery is sub divided into 17 mini galleries

Its a big core...I`d say a good 50% more surface area than standard..its quite heavy but goes from warm to cold very quickly and holds its temp quite well. Just some cutting shaping and welding to do know. More soon This post has been edited by Insanity-74: Jun 4, 2008 - 10:49 AM |

Jun 4, 2008 - 1:04 PM Jun 4, 2008 - 1:04 PM

|

|

|

Enthusiast    Joined Dec 5, '05 From LA, CA Currently Offline Reputation: 1 (100%) |

Well the Core has finally arrived...size is exactly correct...its a shame there are 3 main galleries instead of 4 or 2, but apparently its OK to intersect a core half way across as each gallery is sub divided into 17 mini galleries If you are using a cross-flow front heat exchanger, the 3-core intercooler could help you with water hose routing - wait, are you keeping it a top mount?Its a big core...I`d say a good 50% more surface area than standard..its quite heavy but goes from warm to cold very quickly and holds its temp quite well. Just some cutting shaping and welding to do know. More soon -Charlie -------------------- 2003 Subaru WRX Wagon

1989 Camry Alltrac LE 3S-GTE - SV25/ST205 hybrid 1988 Camry Alltrac LE - BEAMS swap started |

Jun 4, 2008 - 1:54 PM Jun 4, 2008 - 1:54 PM

|

|

|

Enthusiast      Joined Dec 19, '07 From tx Currently Offline Reputation: 22 (100%) |

I'm loving this project.

Insanity-74 - wanna make me one next --------------------  ENGINE: '93 RC 3S-GTE/WRC CT-20b [18-20PSI] PERF: TRD/HKS/ARP/NGK/MSD/ACT/Blitz/STRI/APEX'i/TwosRus/GReddy/Magnaflo/KOYO SUSP: Tein/Bilstein/SusTech/ INT: SS-III SEATS/Toyota Hyper Sports EXT: WRC/TRD/404 Its a safety feature so that people like you don't end up killing themselves or everyone around them. Slow down Paul Walker. 6GC Chat - Go there: [url="http://www.griffgirl.com/forum/chat/index.php[/url] |

Jun 4, 2008 - 2:36 PM Jun 4, 2008 - 2:36 PM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

Well the Core has finally arrived...size is exactly correct...its a shame there are 3 main galleries instead of 4 or 2, but apparently its OK to intersect a core half way across as each gallery is sub divided into 17 mini galleries If you are using a cross-flow front heat exchanger, the 3-core intercooler could help you with water hose routing - wait, are you keeping it a top mount?Its a big core...I`d say a good 50% more surface area than standard..its quite heavy but goes from warm to cold very quickly and holds its temp quite well. Just some cutting shaping and welding to do know. More soon -Charlie Yes i am keeping it top mount...trying to keep it standard looking as possible...I dont have much space anywhwere else. The underside will be heat shielded with a 200deg permanent exposure heat resistant material. |

Jun 4, 2008 - 2:47 PM Jun 4, 2008 - 2:47 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

Nice work, keep us updated !

--------------------  I will return one day. |

Jun 5, 2008 - 9:51 AM Jun 5, 2008 - 9:51 AM

|

|

Enthusiast      Joined Oct 10, '03 From Wichita, KS Currently Offline Reputation: 5 (100%) |

Well the Core has finally arrived...size is exactly correct...its a shame there are 3 main galleries instead of 4 or 2, but apparently its OK to intersect a core half way across as each gallery is sub divided into 17 mini galleries Instead of intersecting the cores half way across why don't you just divide it the other way and have it make one pass through the nine holes on the left of your picture do a loop on the other side of the core and exit the 9 holes on the right. You'd need to divide one end tank in half but I don't think it'd hurt anything... might even distribute the water more evenly throughout the core. --------------------  Project ST204.5 99.88946% complete... |

Jun 5, 2008 - 11:09 AM Jun 5, 2008 - 11:09 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

Well the Core has finally arrived...size is exactly correct...its a shame there are 3 main galleries instead of 4 or 2, but apparently its OK to intersect a core half way across as each gallery is sub divided into 17 mini galleries Instead of intersecting the cores half way across why don't you just divide it the other way and have it make one pass through the nine holes on the left of your picture do a loop on the other side of the core and exit the 9 holes on the right. You'd need to divide one end tank in half but I don't think it'd hurt anything... might even distribute the water more evenly throughout the core. I did consider that, but then you would have half the charge air at a different temp to the other half...I did think of dividing just the centre bit like you sugested..ie the front set of holes and half the middle set in one direction....the other half of the middle section and the back section for flow the other way....if that makes sence. But I have been assured by the makers of the core that it is fine to divide the cores down the middle...time will tell I guess. I`ll try both ways and see which works best. |

Jun 6, 2008 - 10:17 AM Jun 6, 2008 - 10:17 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

Well a bit more done today....by god its hard work...I thought Aliminuim alloy was going to be easy to work in.....nope...to get it to bend at all you have to heat it to near the surfeace of the sun temp that burns you at every available oportunity and slices your skin without a second though...by the time I had lost my second pintof blood I had just about finished the inlet side of the cooler.

Needs finishing a little and welding of course but its near enough ready for welding...had enough now as the loss of blood is making me feel dizzy |

Jun 6, 2008 - 10:20 AM Jun 6, 2008 - 10:20 AM

|

|

|

Enthusiast      Joined Dec 19, '07 From tx Currently Offline Reputation: 22 (100%) |

Looks great. Eat some cookies and drink a bunch of OJ and get back to work

--------------------  ENGINE: '93 RC 3S-GTE/WRC CT-20b [18-20PSI] PERF: TRD/HKS/ARP/NGK/MSD/ACT/Blitz/STRI/APEX'i/TwosRus/GReddy/Magnaflo/KOYO SUSP: Tein/Bilstein/SusTech/ INT: SS-III SEATS/Toyota Hyper Sports EXT: WRC/TRD/404 Its a safety feature so that people like you don't end up killing themselves or everyone around them. Slow down Paul Walker. 6GC Chat - Go there: [url="http://www.griffgirl.com/forum/chat/index.php[/url] |

Jun 6, 2008 - 10:29 AM Jun 6, 2008 - 10:29 AM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

|

Jun 11, 2008 - 6:01 PM Jun 11, 2008 - 6:01 PM

|

|

|

Enthusiast      Joined Dec 19, '07 From tx Currently Offline Reputation: 22 (100%) |

Sorry didn't mean to use the Drill Sergent voice

Any progress? I'm so all about this thread - I'm really thinking [but have not researched much so talking out my ass really] that something like this would benifit the poor 3S's here in Hell - I mean Houston. --------------------  ENGINE: '93 RC 3S-GTE/WRC CT-20b [18-20PSI] PERF: TRD/HKS/ARP/NGK/MSD/ACT/Blitz/STRI/APEX'i/TwosRus/GReddy/Magnaflo/KOYO SUSP: Tein/Bilstein/SusTech/ INT: SS-III SEATS/Toyota Hyper Sports EXT: WRC/TRD/404 Its a safety feature so that people like you don't end up killing themselves or everyone around them. Slow down Paul Walker. 6GC Chat - Go there: [url="http://www.griffgirl.com/forum/chat/index.php[/url] |

Jun 12, 2008 - 5:15 PM Jun 12, 2008 - 5:15 PM

|

|

|

Enthusiast    Joined Jan 9, '05 From Under the car Currently Offline Reputation: 0 (0%) |

I`m still working on it...progress is being made....will post up some pictures when I`m done.....fabrication is about 70% complete...in a few weeks I should be ready for welding......just about ready to make the inlet and outlet pipes. Keep burning myself on the hot metal (needed to bend the alloy) so I`m taking a break for a few days to let the burns heel

|

Jun 14, 2008 - 2:39 AM Jun 14, 2008 - 2:39 AM

|

|

|

Enthusiast   Joined Nov 22, '05 From New Zealand, Hamilton Currently Offline Reputation: 2 (100%) |

Ive been waiting for a long time for your final decision on the set up

and now its finally arrived... its like christmas... cant wait to see the stats, keep it up mate! (glad to see you didnt get put off) |

Jun 14, 2008 - 11:26 AM Jun 14, 2008 - 11:26 AM

|

|

|

Enthusiast    Joined Jul 28, '06 From Delaware Currently Offline Reputation: 0 (0%) |

two pairs of leather gloves, one to wear and one to hold the metal with and you'll be good to go

|

|

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: February 13th, 2025 - 1:51 AM |