|

Mar 7, 2010 - 2:13 PM Mar 7, 2010 - 2:13 PM

|

|

|

Enthusiast Joined Dec 22, '08 Currently Offline Reputation: 0 (0%) |

My timing belt is due for replacement in terms of the years it's done but not the miles. Thought it would be sensible to have a go myself and try and save some cash. I'm following the Chilton Manual plus this guide How To Replace Your Timing Belt on these forums.

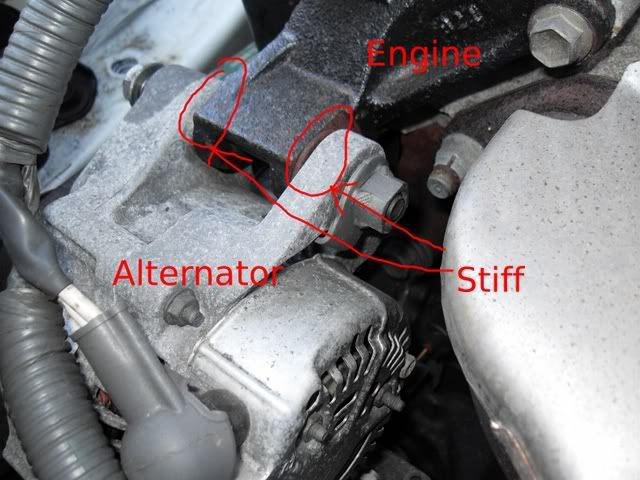

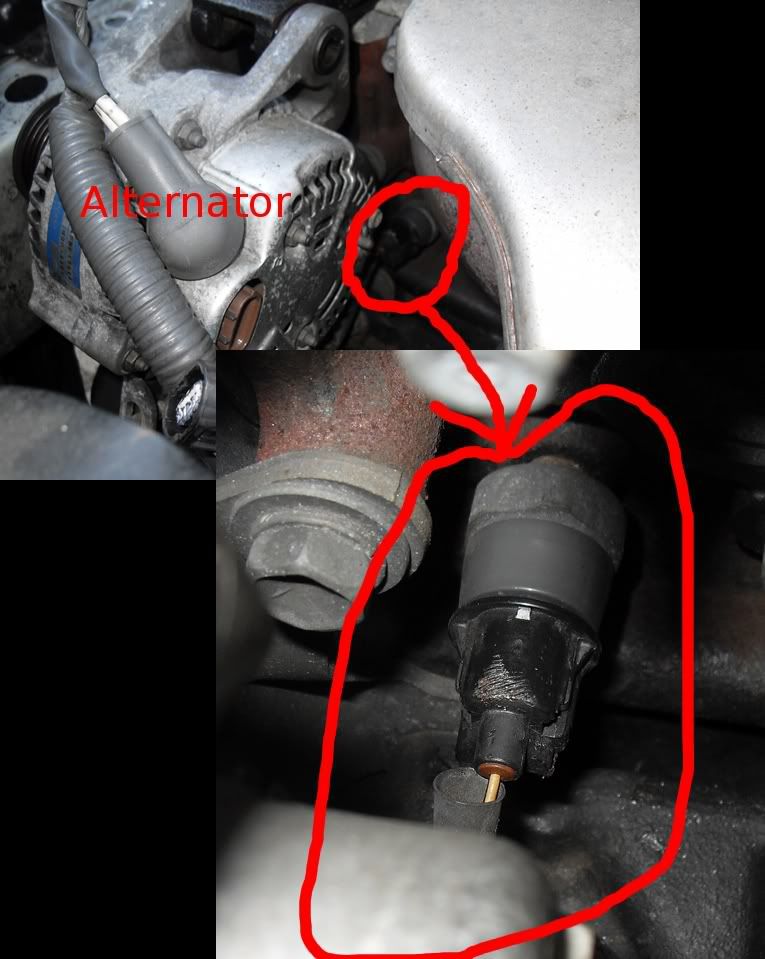

I'm having a mammoth struggle getting rusted up nuts/bolts off hard to reach places such as the 10mm nuts on the water pump pulley and those on the fuse box. Why does Toyota use crappy unplated steel bolts or am I dealing with someone's aftermarket bolt replacement attempt? Still, I'm slowly getting there and replacing bolts with new ones as I go along. Grateful if someone could help me out with some issues. 1. How do you split apart the grey cable harness things in the engine bay? They have a slot in them that looks like you should stick a flat bladed screw driver in then they will split in two but I just can't get them to do that. 2. I've totally undone the pivot bolt on the alternator, and in addition undone the adjustment bolt quite a lot and also loosened the lock bolt; should the alternator be incredibly tightly fitted onto its mount where the pivot bolt goes? I've had to use a hammer to get it do move the alternator off the pivot bolt attachment but this doesn't seem a good idea. This pic shows more (I know the pivot bolt is still in it - this pic was taken before I removed the bolt and gave it a hammering).  3. As I need to remove the alternator in order to continue to the timing belt, how do I detach the wire in the picture below from the engine block? The wire needs to be detached because it also attaches to the alternator which I need to remove. I'm guessing it's a sensor of some kind, I've tried using pliers but they won't pull it out easily and I'm concerned about breaking it.  4. I detached another connector that was plugged into the alternator and it looked like it had white lithium grease in. Do I need to put grease back in it when I eventually plug it back into the alternator.  5. Is this bit of plastic anything to do with my car?!!? I found it nearby and was worried about it.  Many thanks from a concerned newbie mechanic. This post has been edited by smiffythecelica: Mar 7, 2010 - 2:15 PM |

Mar 7, 2010 - 2:51 PM Mar 7, 2010 - 2:51 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

the plastic thing looks like a floor tile spacer

use a prybar/beefy screw driver to move the alt off the pivot and some wd40 will help it along as well. the wire loom (gray stuff) just holds the wires together, don't take it all apart the sensor is for the oil pressure sender, on the bottom is a thingy that presses in to release the connector from the sender. -------------------- |

Mar 8, 2010 - 1:03 AM Mar 8, 2010 - 1:03 AM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

yeah that white thing doesnt belong on the car. as for the sensor you have circled, thats the oil pressure sensor. look at my 7A thread for help on assembling the timing belt

-------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

Mar 8, 2010 - 4:54 PM Mar 8, 2010 - 4:54 PM

|

|

|

Enthusiast Joined Dec 22, '08 Currently Offline Reputation: 0 (0%) |

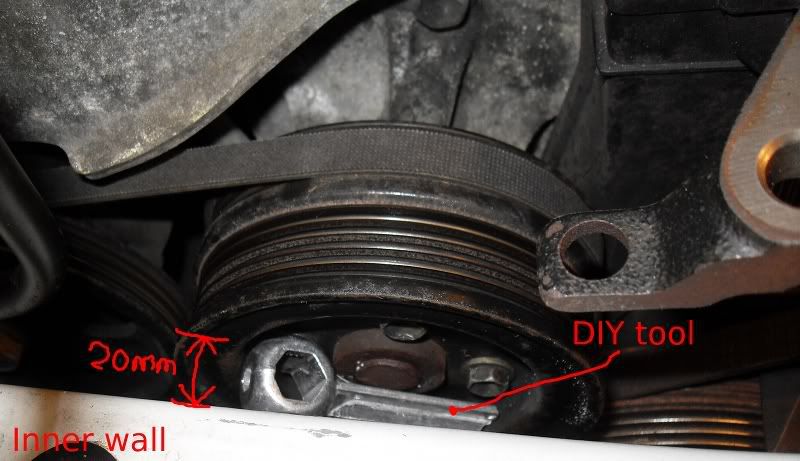

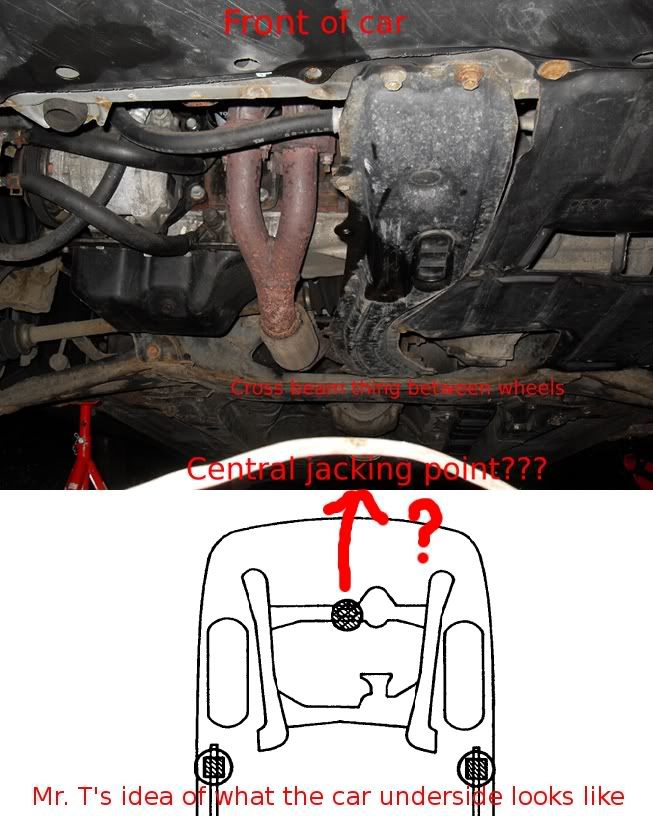

yeah that white thing doesnt belong on the car. as for the sensor you have circled, thats the oil pressure sensor. look at my 7A thread for help on assembling the timing belt Smaay, do you mean the thread where you describe your engine rebuild (an awesome post)? You have 21 pages of posts so it's hard for me to guess exactly which one you mean. Cheers Bitter for the tip on the connector release thing; there's no way I would have found that otherwise. I'll assume that white stuff on the connector isn't significant though I might jam some blu-tac in there when I stick it back together to reduce the chance of it coming apart while the engine is running. A few more questions have come up: 7. What tool should I be using to tighten the water pump pulley bolts? I made a custom tool out of a bike repair tool by filing it down to fit (see below) because the gap between the pulley and the car inner wall is only about 20mm which is too small for a socket set. I tried my 12-point spanner but it started to strip the heads of the bolts. The tool I made isn't really sufficient to tighten the bolts to the required 10Nm.  8. Where is the jack location that is meant to be in the centre of the engine bay? I took a photo of the underside of the car (viewed from the front of the car) and I can't relate it to Toyota's idea of the jacking point location.  9. Regarding the forward side jacking points, am I meant to support the car on the thin ridges of steel (with the two notches in), or is anywhere on the underside of the car near the jacking points okay? I'm trying to use axle stands to support the car on these jacking points so have to use bits of wood between the car and the ridges to not damage them. This doesn't seem right. 9. Assuming my current timing belt is set up correctly, can I just Tippex on the position of the belt teeth relative to the engine and cogs and belt, then transfer them to the new belt teeth? I'm lazy and this seems like a quick way to do things. :-} 10. Does it matter which way round I put the new belt on? I can't see any marks on it or comments in the Chilton manual but friends have warned me about putting it on the wrong way. 11. What are the wheel nut sizes on the Celica? I've tried 20mm and 21mm with no luck on either and also tried imperial. 12. Where is the definitive source for torque settings when tightening bolts? The Chilton manual gives conflicting values on different pages for how much to tighten the right engine insulator nuts for example. I have a collection of PDFs with names like "B emission application.pdf" but I've been over all of them and can't find torque settings. Muchos grasias. This post has been edited by smiffythecelica: Mar 8, 2010 - 5:25 PM |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 24th, 2024 - 12:00 AM |