May 11, 2013 - 11:50 AM May 11, 2013 - 11:50 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

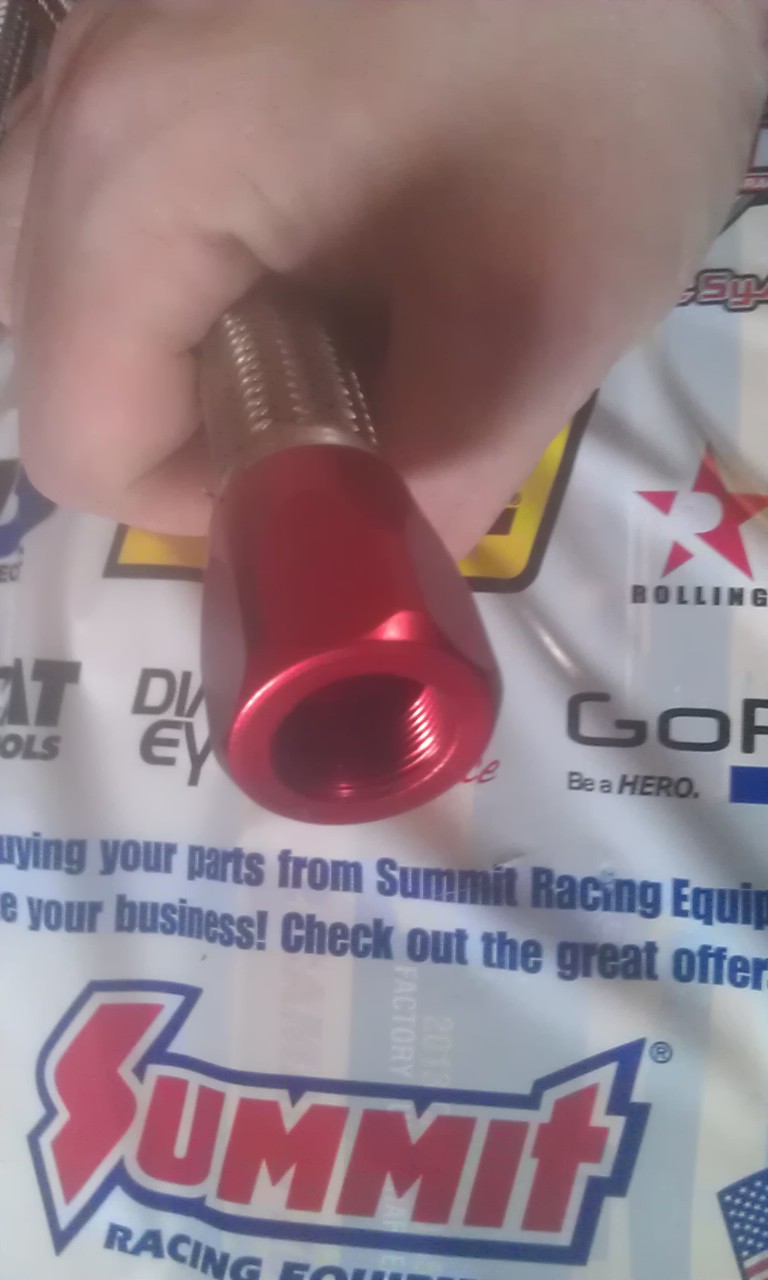

How to Build Stainless Braided "AN" style lines for any application So, You want to build Oil Feed and Drain lines for your new Turbo setup? Or maybe Fuel lines? or Brake lines? Here is a quick, pic based tutorial on how they go together. For this How to, I am building an oil drain line for a turbo setup. First, a quick tip. Once you know your fitting sizes, ect, and are ready to buy your fittings for the hose ends, I would highly suggest always buying "Swivel-Seal" style hose ends. Here is why. When you go to install your lines, if they are not perfectly straight and in line with the fittings, when you got to tighten them down the whole hose and fitting will want to turn, making it very difficult, or sometimes impossible to tighten down without spinning and kinking the line. The Swivel-Seal hose ends are more expensive, but believe me when I say, they are worth it. So, for this particular line, I am using -10an line, and fittings. First, your gonna wanna cut your hose to the appropriate length. Your gonna wanna tape the end of the hose with some masking tape or somthing so that the ends dont get all frayed when you cut it. Use a Cut Off Wheel, or a Hack Saw with a fine toothed metal blade, and you'll end up with somthing like this:  Next, you take apart your Hose End, it will look like this:  Then you pull the tape off the hose you cut, take the red part of the fitting, and push it onto the hose, being careful not to seperate or damage the braiding, like this:  Until its seated all the way in, like this:  Next, You'll wanna either mark the hose with a marker, or with a peice of tape, just behind the fitting you just installed, like this:  So that when you perform this next step, you can be sure your not pushing the hose out of the fitting. Next, take the blue part of the fitting, and install it into the red section, like this:  Sometimes it helps to lube the end of the blue fitting with a tiny bit of oil if its really hard to install. Begin tightening it down slowly, checking to make sure your not pushing the hose end off the hose. When your done, it should look like this:  And thats it! Depending on the size of the hose your making, it can be difficult to tighten them down, so I like to put the hose end into a vice, and use a wrench on the fitting for these larger hoses. Now, here are a few common sizes I've used building diffrent lines over the years that may be helpful down the road. Most Turbo Oil Drain lines will call for either -10, or -12 hose. Turbo oil Feed lines should be either -3, or -4, depending on the manufacturer. precision turbo reccomended -4 for theyre 5857 turbo to me, I use -3 for my 5sfte setup, with a restrictor. For 99.9% of the cars here, -6 line is perfect for fuel line, thread pitch for both the top of 6gc fuel filter, and 3s/5s fuel rail is 12mmx1.25 3rd gen 3sgte oil feed thread pitch is also 12mmx1.25 2nd gen 3sgte oil feed is 18mmx1.5 Enjoy! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

|

Replies

(1 - 13)

May 11, 2013 - 12:18 PM May 11, 2013 - 12:18 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

Nice write up Manny!

Sticky it. |

May 11, 2013 - 12:41 PM May 11, 2013 - 12:41 PM

|

|

|

Enthusiast     Joined Sep 27, '10 From pittsburgh Currently Offline Reputation: 4 (100%) |

Good write up, one thing i'd suggest is using a chisel to cut the ends instead of a cutoff wheel.

No tape necessary, no metal shavings inside the lines. Chisel/sledge two solid hits and it cuts. -------------------- -93 Rx7, Turbo 6.1L v8, 725rwhp/760rwtq

-95 Celica GT Rally Car - 3sge/AWD -10 F150 Always buying stock wheels... PM me if interested in selling. |

May 11, 2013 - 1:28 PM May 11, 2013 - 1:28 PM

|

|

Enthusiast      Joined Jan 4, '12 From US Currently Offline Reputation: 6 (100%) |

Also where to buy the fittings, brands, prices, hose prices and where to get them etc

-------------------- 1993 Celica GT Coupe - sold

1994 Celica GT Liftback |

May 11, 2013 - 2:18 PM May 11, 2013 - 2:18 PM

|

|

|

Enthusiast      Joined Dec 29, '05 From So-Cal Currently Offline Reputation: 12 (100%) |

manny, what are the size fitting for the slave and master clutch cylinder? and the length because my hard lines broke from the master clutch cylinder and want to connect directly from master to slave.

|

May 11, 2013 - 5:45 PM May 11, 2013 - 5:45 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

manny, what are the size fitting for the slave and master clutch cylinder? and the length because my hard lines broke from the master clutch cylinder and want to connect directly from master to slave. I have no idea. I posted the ones I am most familiar with, the rest you guys will have to figure out and add! QUOTE Also where to buy the fittings, brands, prices, hose prices and where to get them etc I normally get anything I need from summit racing.com, they have most everything in stock, have fast shipping, and great return policy. as far as brands, brands like areoquip and earls are top of the line stuff, summit even makes theyre own brand which I've tried and been happy with. pricing varys greatly depending on size and style, I'm not about to sit here and list all the diffrent sizes and prices, lol you guys have to do SOME of the work yourselves. QUOTE Good write up, one thing i'd suggest is using a chisel to cut the ends instead of a cutoff wheel. No tape necessary, no metal shavings inside the lines. Chisel/sledge two solid hits and it cuts. Thats a cool idea, I'll definetly be trying that in the future! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

May 11, 2013 - 8:34 PM May 11, 2013 - 8:34 PM

|

|

|

Enthusiast    Joined Jan 26, '09 From Los Angeles Currently Offline Reputation: 1 (100%) |

Good write up, one thing i'd suggest is using a chisel to cut the ends instead of a cutoff wheel. No tape necessary, no metal shavings inside the lines. Chisel/sledge two solid hits and it cuts. Just gotta make sure that chisel is SHARP though. Otherwise, you'll be pounding on it for awhile and will end up pinching the hose. Good write up though, Manny! I'll be making the fuel lines here soon. -------------------- |

May 12, 2013 - 10:43 AM May 12, 2013 - 10:43 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

I don't think you can make brake hoses that way, every brake hose I've ever seen is crimped together by a high pressure hydraulic machine with a steel collar that's compressed on to make the seal.

-------------------- |

May 12, 2013 - 7:15 PM May 12, 2013 - 7:15 PM

|

|

|

Enthusiast    Joined Mar 24, '11 From 704 Currently Offline Reputation: 3 (100%) |

I dont see why not? The red piece is a tight (really tight) fit on the hose and the blue piece with the tapered end then pushes the hose against the red piece. So its like:

->(<-->)<- Yea, I'm an artist This post has been edited by travisxcore: May 12, 2013 - 7:16 PM |

May 13, 2013 - 10:59 AM May 13, 2013 - 10:59 AM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

good thread, i also add a squirt of WD-40 to help the fitting seat in the hose.

-------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

May 14, 2013 - 7:55 AM May 14, 2013 - 7:55 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

Brake hoses need to withstand thousands of PSI of pressure tens of thousands of times. I don't think threaded AN fittings are designed for more than 1000-1500 PSI, I can't seem to find specs listed but I wouldn't trust that style of fitting to hold a brake hose in a full on pedal to the floor stop.

-------------------- |

May 14, 2013 - 10:04 AM May 14, 2013 - 10:04 AM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

the fitting can handle it, its the hose that has to handle it. most brake lines even though soft, have a Teflon lining in them to give the ability to handle the pressures

-------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

May 16, 2013 - 4:49 PM May 16, 2013 - 4:49 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

yea, now that I think about it, I dunno if these could be used in braking applications, although like smaay said, I would be more concerned with the hose holding the pressure more so than the fitting.

I tried the chisel deal on some -10 line this weekend, and it didnt work, but could have been because of the chisel I used. it was sharp, but not REALLY sharp like a good chisel. I think it definetly would have worked on smaller line, though. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

May 17, 2013 - 8:00 AM May 17, 2013 - 8:00 AM

|

|

|

Enthusiast     Joined Sep 27, '10 From pittsburgh Currently Offline Reputation: 4 (100%) |

yea, now that I think about it, I dunno if these could be used in braking applications, although like smaay said, I would be more concerned with the hose holding the pressure more so than the fitting. I tried the chisel deal on some -10 line this weekend, and it didnt work, but could have been because of the chisel I used. it was sharp, but not REALLY sharp like a good chisel. I think it definetly would have worked on smaller line, though. What type of chissel? I have one thats really solid probably weighs a few lbs, and use a 2.5 lb sledge. I also put it on a piece of aluminum, need a really hard surface on the other side so you can use concrete but it dulls the chissel out. Put the aluminum on the concrete. then hit it. Here's a vid of someone doing it. http://www.youtube.com/watch?v=dkqO6wbKLZg This post has been edited by czwalga: May 17, 2013 - 8:18 AM -------------------- -93 Rx7, Turbo 6.1L v8, 725rwhp/760rwtq

-95 Celica GT Rally Car - 3sge/AWD -10 F150 Always buying stock wheels... PM me if interested in selling. |

|

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 26th, 2024 - 12:27 PM |