Apr 25, 2008 - 10:25 PM Apr 25, 2008 - 10:25 PM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

First of all this is a tough job.... Read all two times before you attempt this and post for extra questions

If you are lloking for something easy, this is not easy I repeat.. x2. The first step is to remove the back seats. here is a basic layout.  The lower seats, comes off easy, all you have to do is lift, and will snap off its position. To remove the Upper seat, you have to remove 4 push pins located on the top side back part of the seat, the part where the velcro is for the boot.  after you haver carefully removed, lift the vynil cover to expose 4 retaining bolts. You will need to use a 13mm socket to remove.  and here is the vert rear strut bar. OEM  To remove the side plastics. First remove the door sills. Then remove two screws at the bottom of the speakers. then remove two screws at the top. One is under the seat belt and the other is the button of the boot. Optional is to remove the seat belt from the floor panel. This is to move away the interior plastic trim. the last thing to remove the plastic trim is two push pins located on the rear, they are hidden and a PITA to put back in.  There is one last push pin on the top You can see it here...  and this is what you get to see, your own car guts... Then remove the exterior weather strip by removing 4-5 screws. dont drop them!  ok, so what now. If you look at the picture above.. you barely see the convertible motor. (Sorry as my collection of pics got lost). But there are approx 3 screws that hold the window track and 4 that hold the window motor to the chassis. They are underneath somewhere. To get to it, you have to remove the speaker plate, the plate that sits on top of the vert top motor and the plate on the bottom that holds the two screws to retain the plastic trim. they all use 10 mm bolts. Here is an exploded overview of the system...  Once you get to view the track screws and motor screws, you have to take the whole system out, but before please do the following!!!! IMPORTANT: bag all screws by location and label bags. You dont want to be guessing afterwards. Take pictures and measurements of the 3 track screws, the distance in mm of how much they are sticking out the nut. As they have to be regulated to the same measurements. The track bots consist of a Long Screw with nut, that are not attached together, they allow to regulate the track. Pics are better to remember. Take notes of the distance between the edges ot the chassis of the car to the window inside and out. The two top screws are easy, the bottom one, I just took a pic before and compared it with another pic after instalation. A BAD REGULATED REAR WINDOW WILL NOT SEAT WITH THE FRONT WINDOW AND WHEN CLOSING THE TOP IT CAN BREAK. So its very important you pay attention, measure and take pics to avoid damage. There is no easy way to do this, if your car is tinted, well, forget about it. This is Real 100% PITA. I pulled it all out at the same time. removed all screws, and brought the whole system out. Another way of doing this: you can disconect the lever from the motor to the window assembly first. Raise the window halfway being a very tight space with a 10 mm IIRC socket disconect the bolt. Watch out for all the parts, as it has washers, springs, etc, dont loose them. (thats why i pulled all at the same time). Dont trust your memory, take pics Then you have to remove the bolts on the track that are called stoppers. These are the wants that prevent the window to keep going up, there are two. That way you be able to pull the window out with the assembly out, by sliding it. Then you unbolt (x3) and pull the track second and unbolt (x 4) and pull the motor out last. always measure your distances distance. (to get an idea how to regulate afterwards) This is your culprit.. priced between 45 and 65 dls at local dealer. The broken bushing. No its not sold separetely. on the picture you can see the arm lever of the motor still attached.  this is your track system, make sure you regrease it properly afterwards....  So another party pooper I ran with was, once i had my plate assemly, how the heck to remove the glass from the old plate, it is held by some weird azz screws, i tried pliers first, no help.... With a dremel tool I created my own weird looking socket tool with pins. You can see i shaved off the sides leaving some pin on the socket. On the side is the aforementioned nasty bolt. It took me hours to figure this one out!  I unbolted the window, then bolted it on the new plate. I do not have torque specs, this is not on the Chilton Manual, so tighten enough, and not to much to break the glass. Next is putting all back together. Please get alcohol, neobacin, and bandaids. This part is 900% PITA and RBH ( rear bu.. H...) Here is what i did. Bolted the motor first. (x 4 Bolts) Bolted the Track second (x 3 bolts) If you measured, it was easy to put it back in place. and regulate temporarily Slide the window plate, carefully. Then have somebody playing with the motor switch, adjusting the arm lever to bring it halfway up. Tighten the arm lever. This is very difficult, youll get cuts, and scrapes. Some parts will fall inside the chassis. So better have a long stick with magnet tip. Believe me, its doable, if its too low then adjust the motor lever higher, or lower. Have a friend play with the switch. After this, replace the stoppers. The best way to adjust the window, is with the top down, and the doors closed, make sure the gap is uniform (window to window), that it slides with no problem and it is not pointing outwards or inwards. (always compare with the opposite windows. remeasure all the gaps and bolts to make sure you have adjusted correctly. To avoid this damage in the future, ALwAYS LOWER YOUR WINDOWS WHEN YOU ARE ABOUT TO CLOSE THE TOP. Closing the top with the windows up, weakens these plastic bushings..... Enjoy, and feel free to sticky. As soon as i find my other pics I will edit to make it more understandable. This post has been edited by njccmd2002: Jul 7, 2011 - 7:19 PM -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

|

Replies

Feb 2, 2015 - 11:25 PM Feb 2, 2015 - 11:25 PM

|

|

|

Enthusiast  Joined Jan 2, '07 From Little Rock, AR Currently Offline Reputation: 0 (0%) |

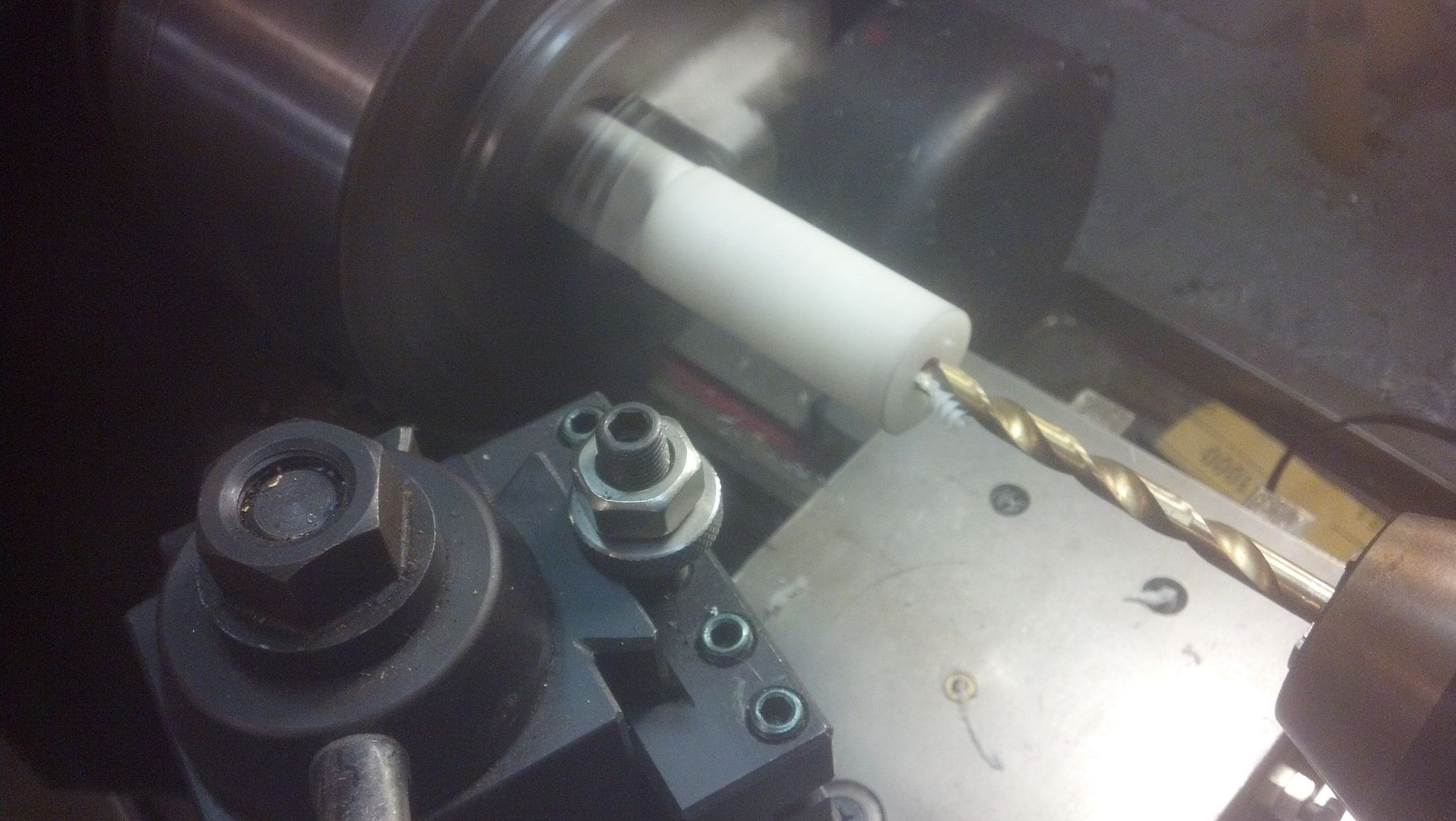

So I got my rear window out yesterday & took a look & two of the three wheels were broken. I decided to try to make my own wheels on the lathe out a piece of delrin. I'm a complete amateur with the lathe, so it took me a few hours measure & set up the work & make 3 of the wheels to try out. Since I think I paid about $80 for this metal part with plastic wheels in it a few years ago on the other side I guess it's worth my time to tinker with it before shelling out that kind of money.

Here I am drilling the center out. The drill bit stays stationary & the plastic is what spins, for those that have never worked with a lathe before. The delrin cuts very nicely.  I then turned the piece down to the proper diameter, & cut the groove to the proper depth, but those pictures where too blurry. Here I am using the cut off tool to remove my new wheel, so I can go on to the next one.  Here are new wheels I made compared to the original ones on the other side. They are only a couple of years old, but had caused me problems due to the the fit being too tight, you can see how the wheels are black in spots, from the paint wearing off the metal track. The stock pieces don't spin while my replacements can spin & rock more freely. This seems to make them slide up & down the track way more smoothly, but time will tell if they last or cause the window to be too loose & rattle.    And installed.  My first wheel was a bit too loose, & I thought it might fall off, so I made an extra, they are both looser than the stock wheels, but they still take some force to go on to the posts. I'll let you know how they fit when I get them installed in the car & if they were out too soon, or cause me other problems. Oh and before any one asks, I think I only paid about $5 for a one foot piece of the Delrin (acetal) plastic online. |

Posts in this topic

njccmd2002 How to Fix the Rear Convertible Window. Apr 25, 2008 - 10:25 PM

njccmd2002 How to Fix the Rear Convertible Window. Apr 25, 2008 - 10:25 PM

palooke nicely done. Please sticky this! Apr 26, 2008 - 7:59 AM

palooke nicely done. Please sticky this! Apr 26, 2008 - 7:59 AM

JonMarkos When I had to replace that plate on mine because o... Apr 26, 2008 - 2:32 PM

JonMarkos When I had to replace that plate on mine because o... Apr 26, 2008 - 2:32 PM

shaunrichard Are you certain you have to remove the upper seat?... Apr 26, 2008 - 6:47 PM

shaunrichard Are you certain you have to remove the upper seat?... Apr 26, 2008 - 6:47 PM

njccmd2002 In my vert, the lower screws are hidden by the low... Apr 26, 2008 - 7:14 PM

njccmd2002 In my vert, the lower screws are hidden by the low... Apr 26, 2008 - 7:14 PM

shaunrichard Good point. I have also found that there are more ... Apr 27, 2008 - 6:16 AM

shaunrichard Good point. I have also found that there are more ... Apr 27, 2008 - 6:16 AM

FlyingBoat Ouch, this looks and sounds difficult!

Both m... May 16, 2008 - 4:47 PM

FlyingBoat Ouch, this looks and sounds difficult!

Both m... May 16, 2008 - 4:47 PM

shaunrichard QUOTE (FlyingBoat @ May 16, 2008 - 4... May 16, 2008 - 4:56 PM

shaunrichard QUOTE (FlyingBoat @ May 16, 2008 - 4... May 16, 2008 - 4:56 PM

FlyingBoat Thanks 'shaunrichard',

Where is the rela... May 22, 2008 - 7:11 PM

FlyingBoat Thanks 'shaunrichard',

Where is the rela... May 22, 2008 - 7:11 PM

shaunrichard QUOTE (njccmd2002 @ Apr 25, 2008 - 11... May 16, 2008 - 7:14 PM

shaunrichard QUOTE (njccmd2002 @ Apr 25, 2008 - 11... May 16, 2008 - 7:14 PM

FlyingBoat What is this #3 part called anyway? I can't se... Jun 2, 2008 - 6:44 PM

FlyingBoat What is this #3 part called anyway? I can't se... Jun 2, 2008 - 6:44 PM

njccmd2002 first of all Doc?

well there are three things ... May 16, 2008 - 7:59 PM

njccmd2002 first of all Doc?

well there are three things ... May 16, 2008 - 7:59 PM

shaunrichard Thanks for the reply. Sorry. I read too much into ... May 16, 2008 - 8:30 PM

shaunrichard Thanks for the reply. Sorry. I read too much into ... May 16, 2008 - 8:30 PM

njccmd2002 QUOTE (shaunrichard @ May 16, 2008 - 9... May 16, 2008 - 8:40 PM

njccmd2002 QUOTE (shaunrichard @ May 16, 2008 - 9... May 16, 2008 - 8:40 PM

6gsillyca Somewhat offtopic, but after the rear seats are ou... May 17, 2008 - 1:35 AM

6gsillyca Somewhat offtopic, but after the rear seats are ou... May 17, 2008 - 1:35 AM

vile_v this is an awesome write up, im going to try this ... May 17, 2008 - 3:36 AM

vile_v this is an awesome write up, im going to try this ... May 17, 2008 - 3:36 AM

njccmd2002 QUOTE (6gsillyca @ May 17, 2008 - 2... May 17, 2008 - 8:07 AM

njccmd2002 QUOTE (6gsillyca @ May 17, 2008 - 2... May 17, 2008 - 8:07 AM

6gsillyca Just drill through this? I checked your other thre... May 17, 2008 - 11:19 AM

6gsillyca Just drill through this? I checked your other thre... May 17, 2008 - 11:19 AM

njccmd2002 QUOTE (6gsillyca @ May 17, 2008 - 12... May 17, 2008 - 9:01 PM

njccmd2002 QUOTE (6gsillyca @ May 17, 2008 - 12... May 17, 2008 - 9:01 PM

njccmd2002 i think the relay is under the left rear speaker, ... May 22, 2008 - 7:15 PM

njccmd2002 i think the relay is under the left rear speaker, ... May 22, 2008 - 7:15 PM

D-Man QUOTE (njccmd2002 @ Apr 25, 2008 - 10... May 23, 2008 - 8:26 AM

D-Man QUOTE (njccmd2002 @ Apr 25, 2008 - 10... May 23, 2008 - 8:26 AM

njccmd2002 nope

Plate Assembly Convertible Jun 2, 2008 - 6:54 PM

njccmd2002 nope

Plate Assembly Convertible Jun 2, 2008 - 6:54 PM

njccmd2002 good and bad news.

Bad: my rear right window bro... Jun 9, 2008 - 5:45 PM

njccmd2002 good and bad news.

Bad: my rear right window bro... Jun 9, 2008 - 5:45 PM

Jedipete Wow those are some mad tech tips. Well I purchased... Jun 10, 2008 - 9:17 PM

Jedipete Wow those are some mad tech tips. Well I purchased... Jun 10, 2008 - 9:17 PM

njccmd2002 QUOTE (Jedipete @ Jun 10, 2008 - 10... Jun 11, 2008 - 8:02 AM

njccmd2002 QUOTE (Jedipete @ Jun 10, 2008 - 10... Jun 11, 2008 - 8:02 AM

Jedipete OOPS forgot one more tip. Instead of Alcohol, Try ... Jun 10, 2008 - 9:27 PM

Jedipete OOPS forgot one more tip. Instead of Alcohol, Try ... Jun 10, 2008 - 9:27 PM

FlyingBoat I did both rear windows along with the help of som... Aug 30, 2008 - 3:37 PM

FlyingBoat I did both rear windows along with the help of som... Aug 30, 2008 - 3:37 PM

pflau OMG OMG OMG OMG OMG

WTF WTF WTF WTF WTF

this see... Sep 6, 2009 - 11:52 PM

pflau OMG OMG OMG OMG OMG

WTF WTF WTF WTF WTF

this see... Sep 6, 2009 - 11:52 PM

njccmd2002 no man, nope, no need to pay that, might as well b... Sep 7, 2009 - 3:24 PM

njccmd2002 no man, nope, no need to pay that, might as well b... Sep 7, 2009 - 3:24 PM

Imawakeyo this is a really awesome thread for us verts. Sham... Jul 7, 2011 - 11:17 AM

Imawakeyo this is a really awesome thread for us verts. Sham... Jul 7, 2011 - 11:17 AM

njccmd2002 what missing pics? Jul 7, 2011 - 7:21 PM

njccmd2002 what missing pics? Jul 7, 2011 - 7:21 PM

Imawakeyo ah disregard I see them now. I had to do this coup... Jul 7, 2011 - 8:11 PM

Imawakeyo ah disregard I see them now. I had to do this coup... Jul 7, 2011 - 8:11 PM

njccmd2002 i know when all else fails go yo junkyard and grab... Jul 7, 2011 - 8:38 PM

njccmd2002 i know when all else fails go yo junkyard and grab... Jul 7, 2011 - 8:38 PM

freddy121389 Rear Window Help

Found this link, helped me a lit... Sep 15, 2011 - 3:14 PM

freddy121389 Rear Window Help

Found this link, helped me a lit... Sep 15, 2011 - 3:14 PM

IllIllIll Thanks a lot for the information. That's why I... Sep 21, 2011 - 7:59 PM

IllIllIll Thanks a lot for the information. That's why I... Sep 21, 2011 - 7:59 PM

Terzin1 pertaining to removing the window:

my passenger s... Oct 7, 2011 - 8:52 AM

Terzin1 pertaining to removing the window:

my passenger s... Oct 7, 2011 - 8:52 AM

njccmd2002 Well ther are 2 versions of vert covers the ones ... Oct 7, 2011 - 11:40 PM

njccmd2002 Well ther are 2 versions of vert covers the ones ... Oct 7, 2011 - 11:40 PM

Araykhel I hate myself for not finding this ages ago, I sus... Oct 10, 2011 - 3:40 PM

Araykhel I hate myself for not finding this ages ago, I sus... Oct 10, 2011 - 3:40 PM

m2736185 Is anyone replacing the broken bushings or do you ... Feb 3, 2012 - 8:43 PM

m2736185 Is anyone replacing the broken bushings or do you ... Feb 3, 2012 - 8:43 PM

njccmd2002 replace the entire bottom assembly. and get it be... Feb 5, 2012 - 2:03 PM

njccmd2002 replace the entire bottom assembly. and get it be... Feb 5, 2012 - 2:03 PM

luisitol QUOTE (njccmd2002 @ Feb 5, 2012 - 2... Feb 28, 2012 - 1:15 PM

luisitol QUOTE (njccmd2002 @ Feb 5, 2012 - 2... Feb 28, 2012 - 1:15 PM

xrav22 QUOTE (luisitol @ Feb 28, 2012 - 1:1... Feb 28, 2012 - 1:32 PM

xrav22 QUOTE (luisitol @ Feb 28, 2012 - 1:1... Feb 28, 2012 - 1:32 PM

luisitol QUOTE (luisitol @ Feb 28, 2012 - 1:1... Feb 28, 2012 - 2:10 PM

luisitol QUOTE (luisitol @ Feb 28, 2012 - 1:1... Feb 28, 2012 - 2:10 PM

m2736185 Where? Are there anymore? Feb 28, 2012 - 6:07 PM

m2736185 Where? Are there anymore? Feb 28, 2012 - 6:07 PM

xrav22 QUOTE (m2736185 @ Feb 28, 2012 - 6:0... Feb 28, 2012 - 9:29 PM

xrav22 QUOTE (m2736185 @ Feb 28, 2012 - 6:0... Feb 28, 2012 - 9:29 PM

CAGirl QUOTE (njccmd2002 @ Apr 25, 2008 - 11... Mar 20, 2012 - 3:41 PM

CAGirl QUOTE (njccmd2002 @ Apr 25, 2008 - 11... Mar 20, 2012 - 3:41 PM

njccmd2002 the plastic gets worn out and cracks, its 10 yer o... Mar 21, 2012 - 3:03 PM

njccmd2002 the plastic gets worn out and cracks, its 10 yer o... Mar 21, 2012 - 3:03 PM

CAGirl Again, great instructional, though I don't see... Jul 19, 2012 - 2:20 PM

CAGirl Again, great instructional, though I don't see... Jul 19, 2012 - 2:20 PM

njccmd2002 i can see the pics well, this is a job that its no... Jul 19, 2012 - 7:59 PM

njccmd2002 i can see the pics well, this is a job that its no... Jul 19, 2012 - 7:59 PM

FrankB2 QUOTE (njccmd2002 @ May 16, 2008 - 7... Feb 12, 2013 - 9:15 AM

FrankB2 QUOTE (njccmd2002 @ May 16, 2008 - 7... Feb 12, 2013 - 9:15 AM

tymish I have a 1995 Convertible and just replaced the re... May 13, 2013 - 12:55 PM

tymish I have a 1995 Convertible and just replaced the re... May 13, 2013 - 12:55 PM

97Celica QUOTE (tymish @ May 13, 2013 - 12:55... Jan 24, 2018 - 12:50 AM

97Celica QUOTE (tymish @ May 13, 2013 - 12:55... Jan 24, 2018 - 12:50 AM

SteveO I have one related question, which I hope is simpl... Aug 8, 2014 - 9:01 PM

SteveO I have one related question, which I hope is simpl... Aug 8, 2014 - 9:01 PM

Alleyoop [quote name='njccmd2002' date='Apr 25,... Dec 19, 2014 - 1:50 PM

Alleyoop [quote name='njccmd2002' date='Apr 25,... Dec 19, 2014 - 1:50 PM

njccmd2002 Post pics with photobucket or any pic service. I ... Dec 24, 2014 - 9:45 AM

njccmd2002 Post pics with photobucket or any pic service. I ... Dec 24, 2014 - 9:45 AM

IllIllIll I'm finally getting around to doing this on my... Feb 1, 2015 - 5:32 PM

IllIllIll I'm finally getting around to doing this on my... Feb 1, 2015 - 5:32 PM

sandusky1977 Did you make any extras? I've been thinking of... Nov 23, 2016 - 10:48 AM

sandusky1977 Did you make any extras? I've been thinking of... Nov 23, 2016 - 10:48 AM

isaiahy Thanks for the write up. I hope to be able to foll... Apr 4, 2018 - 12:50 PM

isaiahy Thanks for the write up. I hope to be able to foll... Apr 4, 2018 - 12:50 PM

SprinterFS @OP: Is there any chance that you still have the p... May 6, 2018 - 6:50 PM

SprinterFS @OP: Is there any chance that you still have the p... May 6, 2018 - 6:50 PM  |

4 User(s) are reading this topic (4 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 23rd, 2024 - 11:37 AM |