Jan 29, 2007 - 2:23 AM Jan 29, 2007 - 2:23 AM

|

|

Administrator      Joined Aug 23, '02 From Seattle, WA Currently Offline Reputation: 14 (100%) |

Over the past few days, I've finally had time to touch my car after months of not being able to work on it because of school and work.

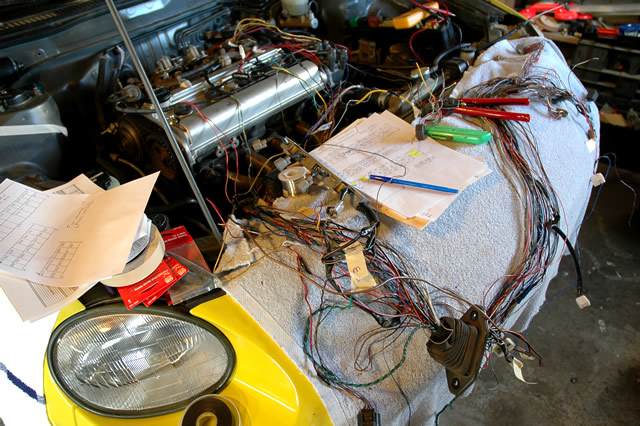

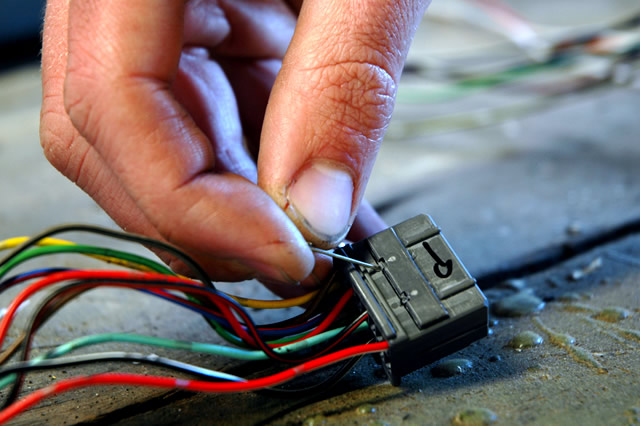

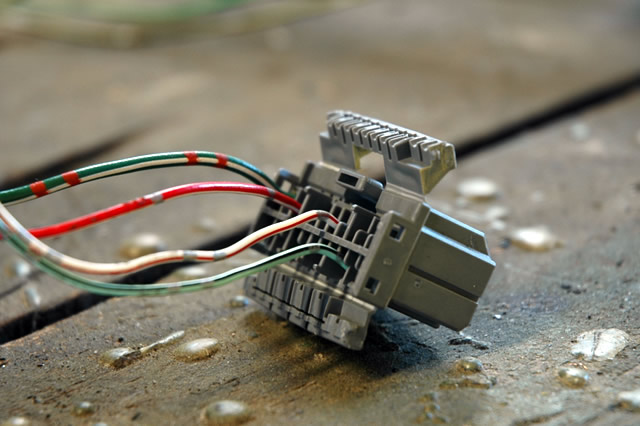

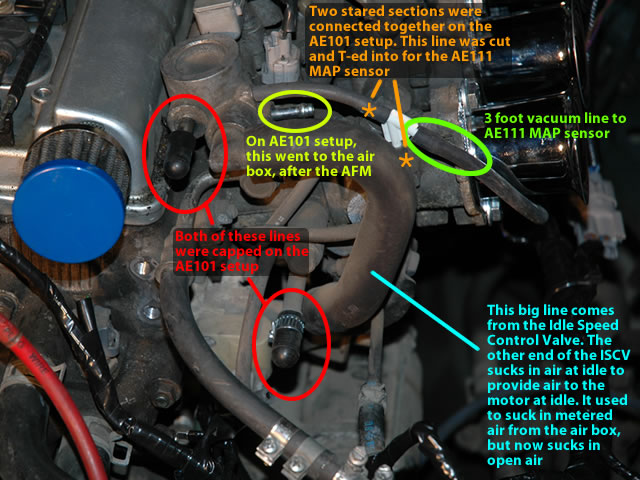

A while ago, I came across a good deal on an AE111 ECU. I bought the ECU, and have been working to get my silvertop 4A-GE running on the new ECU. This thread will document some parts of the AE111 conversion. First things first, I had to get the old wiring out of the car. Because of my stupid old wiring setup, the harness was squeezed between the intake manifold and valve cover, so I had to remove the valve cover to get the harness out.  Then I removed the passenger seat and parts of the dash for easy access to the ECU and body harness plugs.  I took notes of where every wire went on the ECU plugs and body harness plugs, and I then proceeded to start unlooming the harness. Some things had to be cut, so I took good notes and labeled wires before I cut them.  I continued removing stuff...I found it easier to work with the throttle cable and stuff out of the way. Individual throttle bodies...mmmmm...  Finally, I got the entire harness unloomed. As I took notes and unloomed the harness, I came across some interesting things. First off, my knock sensor was spliced into a ground wire before it made it to the ECU...I'm sure that wasn't good. Also, my oxygen sensor was wired incorrectly, with both white wires of the Bosch four-wire oxygen sensor going to the HT pin on the AE101 ECU. Also, the black ground wire of the oxygen sensor was grounded to a chassis ground point, not the sensor ground pin on the ECU. Here is the unloomed harness. You can see some of my notes on this photo. I took tons of notes so that I could put everything back to the way it was if desired.  Once I had everything unloomed, I began modifying the harness to suit my new ECU, which has a significant number of changes as far as where wires go on the ECU plugs. Also, I had to remove the AFM plug and add plugs for an intake air temperature sensor (that I got from a fifth gen. Celica ST) and a manifold absolute pressure sensor (that I got from a sixth gen. Celica ST.) None of the body harness plugs had to be changed, except for the circuit opening relay, which now gets its FC signal from the ECU, rather than the AFM on the old setup. To minimize soldering joints and keep things clean, I de-pinned my ECU plugs, removed un-necessary wires, and moved pins around. I highly recommend that you do this, as it keeps things clean and it's easy once you know how to de-pin those plugs. For most Toyota plugs, there is a lock that pries up with something small and pointy, like a safety pin. This must be pulled up before pins can be removed.  On a Honda plug (I found my 22-pin ECU plug from a '94 or '95 Honda Accord because I couldn't find a suitable one on a Toyota,) the locks are different, and are simply flaps at the back of the plug that must be pried open, like in the photo below.  Once the lock is unlocked, you can see tabs in the side opposite of the wires (the side that plugs into whatever...in my case, the ECU.) These tabs must be pried up with something like a safety pin, and then once they're up, the pins will pull out from the wire-side of the plug. It takes some patience to get the hang of it, or at least it did for me, but once you've got it figured out it becomes easy. And by the way, the pins just push right back in and snap into place. And I found that the Toyota pins are not interchangeable with the Honda pins. And also, the pins vary in size and not every pin will work in every connector, or even in different parts of the same connector. With the ECU plug pins moved, I completed most of the connections on my harness. I then triple checked all of my connections, tracing them out by hand and with the multimeter to ensure correctness. Once I was pretty confident that my wiring was correct, I taped the harness up a bit, plugged everything in, and prepared to hook up the battery and start up the car. I hooked up the battery and listened and looked for anything out of the ordinary, like wires getting hot or burning, etc. Everything seemed fine, so I put the car in diagnostic mode. To do this, you short the TE1 pin on the ECU to the E1 ECU pin, at least in my case, because I removed my diagnostic box. Once in diagnostic mode, I turned the car to on, but didn't start it yet. The check engine light began flashing, indicating that I have a code 21, or a miswired oxygen sensor. After talking with Dr. Tweak, he kindly told me that I shouldn't have had both white wires of the oxygen sensor wired to the HT ECU pin, and that one of the wires should go to ignition power. Once I made the change, my code went away, and I had no more codes, which is indicated by a constantly quick flashing check engine light when in diagnostic mode. With no more codes, it was time to start the car. I made sure all my wiring was out of the way, vacuum lines were in order, etc., and then I cranked the car, and it fired right up instantly. I ran around ensuring that everything looked normal and nothing was burning or acting strangely, and then I let the ECU adjust itself over a period of a few minutes. At this point, the bay looked like this.  With wires everywhere and things like the IAT and MAP sensors just sitting there, I couldn't drive the car, so I just revved the car a couple times, and wow, the sound of the open throttle bodies is amazing. Everything seemed to be in order, so I turned the car off, checked for codes again in diagnostic mode, and found none. I then removed the battery and removed the harness so that I could finish it up and loom everything up. Before the weekend, my velocity stacks arrived, so I had to modify them to fit my intake manifold.  As you can see, the place where the holes were was cut, so that now there are notches. This was done because the holes didn't match the holes on my intake manifold, which are a little bit further apart than the velocity stacks. I then bolted them on, loomed up the harness, cleaned up some vacuum line routing, installed the VVT plug and OEM Toyota coil (from a ST164 Celica with a 3S-GE,) and then hooked the battery back up. When all of this was done, the bay still wasn't complete, but it was clean enough to go for a drive.  So I started the car, checked for codes, found none, and proceeded to let the car warm up and adjust itself. Once adjusted and warmed up, I went for a drive, with mixed emotions. First off, the car absolutely screams at wide open throttle. The sound of the air rushing through the velocity stacks and into the individual throttle bodies at full throttle is indescribable. It's crazy loud and sounds kind of like DOHC VTEC on steroids. That said however, the car is running like crap. At partial throttle, the car has virtually no power, and when you do floor it you don't get instant throttle response like before. Instead, the car feels like it bogs down and hesitates for a moment, and then it gets fast and runs well until redline. Also, the idle remains at 1500 RPM. I'm pretty sure it's a vacuum issue, and this is the point that I'm stuck at right now. Here is my current vacuum setup.  First off, take note of vacuum spot circled in yellow. First, I had that spot connected to a line, to a metal tube, to another line, to another metal tube, and finally to another smaller rubber line that was open. When I first had the car running on the new ECU, this was how it was, and the car idled at 900 RPM just as it should and revved just fine. So when I was removing extra vacuum lines, I removed the extra lines and tubes and crap from that vacuum spot that eventually just were open. But I'm thinking that the smaller line that eventually just went to the atmosphere must have restricted airflow a bit. This vacuum spot initially went to the intake manifold plenum, after the AFM and before the ITBs, and is supposedly the "power steering rack and pinion's vacuum idle up valve / compensator return hole" according to this site. But anyway, after reading the explanation on that site, I tried capping that vacuum spot, pulled the EFI fuse so the ECU could reset, and then started the car and let it adjust. Idle was fine, at about 900 RPM, but when I revved the motor, the response was VERY laggy. So as the car was running, I removed the cap, and the idle went up, but immediately, the engine would again rev instantly. I shut off the car and reset the ECU again, and the car idled very high on immediate startup (like 2500 RPM...about 500 higher than normal when it's first adjusting) and once it was adjusted, the idle was still at 1500 RPM. This is the current state that the car is in, and when I was driving the car, this is how it was. I'm thinking that perhaps that vacuum line has to do with my high idle and bad driveability problems. Anyone have any ideas there? Or, perhaps it could be my three foot long vacuum line to my MAP sensor I'm thinking. On the Toyotas I've seen, it's typically been short, like 6-9" or so, but mine is quite a bit longer to accomodate my hidden remote mounting location for the MAP sensor. I'm guessing that three feet is too long...anyone have any input? Keep in mind that the car idled and ran beautifully before I swapped in the new ECU. And I'm not throwing any codes at all at the moment. What do you guys think? And any comments thus far are welcome as well...I'll be adding to this thread as I accomplish more on the car. -------------------- New Toyota project coming soon...

|

|

Replies

Jan 29, 2007 - 1:04 PM Jan 29, 2007 - 1:04 PM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

awesome! ITB FTW.

love the pics they are so good! -------------------- |

Posts in this topic

Coomer My Engine Bay Renovation Thread Jan 29, 2007 - 2:23 AM

Coomer My Engine Bay Renovation Thread Jan 29, 2007 - 2:23 AM

Bigmeanbulldog55 When I started reading I didn't know why you w... Jan 29, 2007 - 9:44 AM

Bigmeanbulldog55 When I started reading I didn't know why you w... Jan 29, 2007 - 9:44 AM

doGGy Chris - i ENVY you so damn much.... ITB's o... Jan 29, 2007 - 10:20 AM

doGGy Chris - i ENVY you so damn much.... ITB's o... Jan 29, 2007 - 10:20 AM

Chanh55 I demand some footage of the engine at idle. =) Jan 29, 2007 - 1:08 PM

Chanh55 I demand some footage of the engine at idle. =) Jan 29, 2007 - 1:08 PM

eggman40 QUOTE(Chanh55 @ Jan 29, 2007 - 10:08... Jan 29, 2007 - 1:27 PM

eggman40 QUOTE(Chanh55 @ Jan 29, 2007 - 10:08... Jan 29, 2007 - 1:27 PM

hitcachi Might be a vacuum line causing your problems, or i... Jan 29, 2007 - 1:49 PM

hitcachi Might be a vacuum line causing your problems, or i... Jan 29, 2007 - 1:49 PM

WannabeGT4 I'm not a silver top guru or anything but I... Jan 29, 2007 - 3:57 PM

WannabeGT4 I'm not a silver top guru or anything but I... Jan 29, 2007 - 3:57 PM

netrata Hey Coomer, try putting back all of the smaller va... Jan 29, 2007 - 4:15 PM

netrata Hey Coomer, try putting back all of the smaller va... Jan 29, 2007 - 4:15 PM

lagos nice job coomer! make some vids of how it sou... Jan 29, 2007 - 4:29 PM

lagos nice job coomer! make some vids of how it sou... Jan 29, 2007 - 4:29 PM

Coomer Thanks for the advice guys. I'll definitely ge... Jan 29, 2007 - 4:58 PM

Coomer Thanks for the advice guys. I'll definitely ge... Jan 29, 2007 - 4:58 PM

Drew-887 Its cool to see someone building up a 4age Slivert... Jan 29, 2007 - 5:28 PM

Drew-887 Its cool to see someone building up a 4age Slivert... Jan 29, 2007 - 5:28 PM

Coomer QUOTE(Drew-887 @ Jan 29, 2007 - 2... Jan 29, 2007 - 5:38 PM

Coomer QUOTE(Drew-887 @ Jan 29, 2007 - 2... Jan 29, 2007 - 5:38 PM

Bigmeanbulldog55 QUOTE(Coomer @ Jan 29, 2007 - 5:38 P... Jan 29, 2007 - 7:30 PM

Bigmeanbulldog55 QUOTE(Coomer @ Jan 29, 2007 - 5:38 P... Jan 29, 2007 - 7:30 PM

Coomer QUOTE(Bigmeanbulldog55 @ Jan 29, 2007 - ... Jan 29, 2007 - 7:52 PM

Coomer QUOTE(Bigmeanbulldog55 @ Jan 29, 2007 - ... Jan 29, 2007 - 7:52 PM

Chanh55 There's not a filter or anything? Jan 29, 2007 - 5:50 PM

Chanh55 There's not a filter or anything? Jan 29, 2007 - 5:50 PM

Bitter i think you should try to put the intake manifold ... Jan 29, 2007 - 6:29 PM

Bitter i think you should try to put the intake manifold ... Jan 29, 2007 - 6:29 PM

Coomer QUOTE(Chanh55 @ Jan 29, 2007 - 2:50 ... Jan 29, 2007 - 6:52 PM

Coomer QUOTE(Chanh55 @ Jan 29, 2007 - 2:50 ... Jan 29, 2007 - 6:52 PM

Bitter QUOTE(Coomer @ Jan 29, 2007 - 6:52 P... Jan 29, 2007 - 8:26 PM

Bitter QUOTE(Coomer @ Jan 29, 2007 - 6:52 P... Jan 29, 2007 - 8:26 PM

WannabeGT4 About the O2 sensor... You said it was hooked up j... Jan 29, 2007 - 6:56 PM

WannabeGT4 About the O2 sensor... You said it was hooked up j... Jan 29, 2007 - 6:56 PM

Coomer QUOTE(WannabeGT4 @ Jan 29, 2007 - 3... Jan 29, 2007 - 7:08 PM

Coomer QUOTE(WannabeGT4 @ Jan 29, 2007 - 3... Jan 29, 2007 - 7:08 PM

97lestyousay Nice work. That wiring looks like a nightmare to ... Jan 29, 2007 - 7:38 PM

97lestyousay Nice work. That wiring looks like a nightmare to ... Jan 29, 2007 - 7:38 PM

Coomer What's a DVOM?

And unfortunately, the Club4AG... Feb 2, 2007 - 4:03 PM

Coomer What's a DVOM?

And unfortunately, the Club4AG... Feb 2, 2007 - 4:03 PM

97lestyousay QUOTE(Coomer @ Feb 2, 2007 - 1:03 PM... Feb 2, 2007 - 7:39 PM

97lestyousay QUOTE(Coomer @ Feb 2, 2007 - 1:03 PM... Feb 2, 2007 - 7:39 PM

Bitter dvom is a fancy term for a multimeter

knowing wh... Feb 2, 2007 - 7:05 PM

Bitter dvom is a fancy term for a multimeter

knowing wh... Feb 2, 2007 - 7:05 PM

Coomer Ah ok, I figured that's what you meant but was... Feb 2, 2007 - 7:35 PM

Coomer Ah ok, I figured that's what you meant but was... Feb 2, 2007 - 7:35 PM

Coomer Last weekend I checked my timing and it's adva... Feb 5, 2007 - 1:17 PM

Coomer Last weekend I checked my timing and it's adva... Feb 5, 2007 - 1:17 PM

soulshadow The yellow part u circled was for the A/C when it ... Feb 5, 2007 - 2:59 PM

soulshadow The yellow part u circled was for the A/C when it ... Feb 5, 2007 - 2:59 PM

playr158 chris are you running anything else on the same li... Feb 5, 2007 - 3:02 PM

playr158 chris are you running anything else on the same li... Feb 5, 2007 - 3:02 PM

lagos coomer...

so you reinstalled the stock intake ma... Feb 5, 2007 - 3:51 PM

lagos coomer...

so you reinstalled the stock intake ma... Feb 5, 2007 - 3:51 PM

Coomer QUOTE(soulshadow @ Feb 5, 2007 - 11... Feb 5, 2007 - 5:01 PM

Coomer QUOTE(soulshadow @ Feb 5, 2007 - 11... Feb 5, 2007 - 5:01 PM

Bitter you can use a multi meter to read the narrowband, ... Feb 5, 2007 - 6:56 PM

Bitter you can use a multi meter to read the narrowband, ... Feb 5, 2007 - 6:56 PM

Kwanza26 QUOTE(Bitter @ Feb 5, 2007 - 11:56 P... Feb 5, 2007 - 8:24 PM

Kwanza26 QUOTE(Bitter @ Feb 5, 2007 - 11:56 P... Feb 5, 2007 - 8:24 PM

Bitter nah, the narrow bands swing at idle and closed loo... Feb 5, 2007 - 9:04 PM

Bitter nah, the narrow bands swing at idle and closed loo... Feb 5, 2007 - 9:04 PM

Coomer Thanks for the advice guys.

Bee, I'd do that,... Feb 5, 2007 - 11:00 PM

Coomer Thanks for the advice guys.

Bee, I'd do that,... Feb 5, 2007 - 11:00 PM

Kwanza26 QUOTE(Coomer @ Feb 6, 2007 - 4:00 AM... Feb 6, 2007 - 6:46 PM

Kwanza26 QUOTE(Coomer @ Feb 6, 2007 - 4:00 AM... Feb 6, 2007 - 6:46 PM

Coomer Thanks for the advice Bee. I think where I have ta... Feb 6, 2007 - 11:04 PM

Coomer Thanks for the advice Bee. I think where I have ta... Feb 6, 2007 - 11:04 PM

netrata Coomer,

I stumbled on this on ebay from a good sel... Feb 7, 2007 - 1:21 AM

netrata Coomer,

I stumbled on this on ebay from a good sel... Feb 7, 2007 - 1:21 AM

Coomer Thanks for the link, but I don't think I want ... Feb 7, 2007 - 3:23 AM

Coomer Thanks for the link, but I don't think I want ... Feb 7, 2007 - 3:23 AM

blazin674 very nice work, this is my first post here but i h... Feb 7, 2007 - 4:24 PM

blazin674 very nice work, this is my first post here but i h... Feb 7, 2007 - 4:24 PM

Coomer QUOTE(blazin674 @ Feb 7, 2007 - 1:24... Feb 7, 2007 - 4:38 PM

Coomer QUOTE(blazin674 @ Feb 7, 2007 - 1:24... Feb 7, 2007 - 4:38 PM

jcbass7 Good luck coomer,

I never realized how nice your ... Feb 7, 2007 - 4:42 PM

jcbass7 Good luck coomer,

I never realized how nice your ... Feb 7, 2007 - 4:42 PM

blazin674 did you happen to get the ae111 manual i know ther... Feb 8, 2007 - 6:47 AM

blazin674 did you happen to get the ae111 manual i know ther... Feb 8, 2007 - 6:47 AM

Coomer QUOTE(blazin674 @ Feb 8, 2007 - 3:47... Feb 8, 2007 - 1:40 PM

Coomer QUOTE(blazin674 @ Feb 8, 2007 - 3:47... Feb 8, 2007 - 1:40 PM

95CelicaST QUOTEYep, I've got it, along with tons and ton... Feb 8, 2007 - 7:00 PM

95CelicaST QUOTEYep, I've got it, along with tons and ton... Feb 8, 2007 - 7:00 PM

Coomer Actually, my bad idle came back with the new vacuu... Feb 9, 2007 - 2:26 PM

Coomer Actually, my bad idle came back with the new vacuu... Feb 9, 2007 - 2:26 PM

Coomer As promised, here are my notes...they're not a... Feb 9, 2007 - 9:12 PM

Coomer As promised, here are my notes...they're not a... Feb 9, 2007 - 9:12 PM

Batman722 ^^ great scribbles Coomer. After reading this post... Feb 9, 2007 - 10:40 PM

Batman722 ^^ great scribbles Coomer. After reading this post... Feb 9, 2007 - 10:40 PM

Coomer It's finally running right! Today I remove... Feb 11, 2007 - 7:28 PM

Coomer It's finally running right! Today I remove... Feb 11, 2007 - 7:28 PM

netrata Yeah I would recheck the timing again and readjust... Feb 11, 2007 - 8:04 PM

netrata Yeah I would recheck the timing again and readjust... Feb 11, 2007 - 8:04 PM

OOBE Good stuff, C. It was really stressing me out know... Feb 11, 2007 - 9:33 PM

OOBE Good stuff, C. It was really stressing me out know... Feb 11, 2007 - 9:33 PM

GTSOwner Now that it's running right, how about a coupl... Feb 12, 2007 - 7:10 AM

GTSOwner Now that it's running right, how about a coupl... Feb 12, 2007 - 7:10 AM

Bitter check the intake cam timing, usually when it back ... Feb 12, 2007 - 10:27 AM

Bitter check the intake cam timing, usually when it back ... Feb 12, 2007 - 10:27 AM

x_itchy_b_x awesome to hear! im sure that it sounds amazin... Feb 12, 2007 - 10:37 AM

x_itchy_b_x awesome to hear! im sure that it sounds amazin... Feb 12, 2007 - 10:37 AM

MtyMseHarmer Glad to hear you got your conversion setup running... Feb 12, 2007 - 3:47 PM

MtyMseHarmer Glad to hear you got your conversion setup running... Feb 12, 2007 - 3:47 PM

Coomer QUOTE(MtyMseHarmer @ Feb 12, 2007 - 12... Feb 12, 2007 - 3:57 PM

Coomer QUOTE(MtyMseHarmer @ Feb 12, 2007 - 12... Feb 12, 2007 - 3:57 PM

vsideboy nice work mate, alot of head scratching and sleepl... Feb 13, 2007 - 2:17 AM

vsideboy nice work mate, alot of head scratching and sleepl... Feb 13, 2007 - 2:17 AM

Drew-887 Any vids??? Feb 13, 2007 - 12:22 PM

Drew-887 Any vids??? Feb 13, 2007 - 12:22 PM

Coomer QUOTE(Drew-887 @ Feb 13, 2007 - 9... Feb 13, 2007 - 2:49 PM

Coomer QUOTE(Drew-887 @ Feb 13, 2007 - 9... Feb 13, 2007 - 2:49 PM

x_itchy_b_x that would look CLEAN!! go for it, your wo... Feb 13, 2007 - 3:06 PM

x_itchy_b_x that would look CLEAN!! go for it, your wo... Feb 13, 2007 - 3:06 PM

celicaST thats a lot of work for cosmetics, but it would lo... Feb 13, 2007 - 3:58 PM

celicaST thats a lot of work for cosmetics, but it would lo... Feb 13, 2007 - 3:58 PM

Coomer QUOTE(celicaST @ Feb 13, 2007 - 12:5... Feb 13, 2007 - 4:01 PM

Coomer QUOTE(celicaST @ Feb 13, 2007 - 12:5... Feb 13, 2007 - 4:01 PM

celicaST QUOTE(Coomer @ Feb 13, 2007 - 2:01 P... Feb 13, 2007 - 4:13 PM

celicaST QUOTE(Coomer @ Feb 13, 2007 - 2:01 P... Feb 13, 2007 - 4:13 PM

Coomer That is a lot of yellow, but that bay is also very... Feb 13, 2007 - 5:18 PM

Coomer That is a lot of yellow, but that bay is also very... Feb 13, 2007 - 5:18 PM

phonex98 "

# Replace flywheel with a lightweight one... Feb 13, 2007 - 5:59 PM

phonex98 "

# Replace flywheel with a lightweight one... Feb 13, 2007 - 5:59 PM

Coomer QUOTE(phonex98 @ Feb 13, 2007 - 2:59... Feb 13, 2007 - 7:34 PM

Coomer QUOTE(phonex98 @ Feb 13, 2007 - 2:59... Feb 13, 2007 - 7:34 PM

phonex98 Good to know I was going to put a light weight fl... Feb 14, 2007 - 2:11 AM

phonex98 Good to know I was going to put a light weight fl... Feb 14, 2007 - 2:11 AM

Coomer Today I checked the timing again, and it looks lik... Feb 15, 2007 - 9:23 PM

Coomer Today I checked the timing again, and it looks lik... Feb 15, 2007 - 9:23 PM

JesterDC QUOTE(Coomer @ Feb 15, 2007 - 10:23 ... Feb 15, 2007 - 10:14 PM

JesterDC QUOTE(Coomer @ Feb 15, 2007 - 10:23 ... Feb 15, 2007 - 10:14 PM

Coomer I do want my car to suck...massive amounts of air ... Feb 16, 2007 - 12:22 AM

Coomer I do want my car to suck...massive amounts of air ... Feb 16, 2007 - 12:22 AM

JesterDC A little orginization would not be a bad thing, lo... Feb 16, 2007 - 7:29 AM

JesterDC A little orginization would not be a bad thing, lo... Feb 16, 2007 - 7:29 AM

Coomer QUOTE(JesterDC @ Feb 16, 2007 - 4:29... Feb 16, 2007 - 10:21 AM

Coomer QUOTE(JesterDC @ Feb 16, 2007 - 4:29... Feb 16, 2007 - 10:21 AM

x_itchy_b_x i read some where that they intentionally stagger ... Feb 16, 2007 - 12:02 PM

x_itchy_b_x i read some where that they intentionally stagger ... Feb 16, 2007 - 12:02 PM

Coomer Well, they're sure not staggered much.

I was... Feb 16, 2007 - 2:02 PM

Coomer Well, they're sure not staggered much.

I was... Feb 16, 2007 - 2:02 PM

x_itchy_b_x QUOTE(Coomer @ Feb 16, 2007 - 4:02 P... Feb 16, 2007 - 3:05 PM

x_itchy_b_x QUOTE(Coomer @ Feb 16, 2007 - 4:02 P... Feb 16, 2007 - 3:05 PM

Coomer Interesting...that doesn't seem like it'd ... Feb 16, 2007 - 3:57 PM

Coomer Interesting...that doesn't seem like it'd ... Feb 16, 2007 - 3:57 PM

95CelicaST A friend of mine has velosity stacks, and his are ... Feb 16, 2007 - 5:16 PM

95CelicaST A friend of mine has velosity stacks, and his are ... Feb 16, 2007 - 5:16 PM

Coomer Yesterday I went ahead and started working on the ... Feb 18, 2007 - 10:09 PM

Coomer Yesterday I went ahead and started working on the ... Feb 18, 2007 - 10:09 PM

x_itchy_b_x LOL coomer im cleaning my bay out so it looks like... Feb 19, 2007 - 1:18 AM

x_itchy_b_x LOL coomer im cleaning my bay out so it looks like... Feb 19, 2007 - 1:18 AM

Coomer I ended up coming home last night, so I wasn't... Feb 19, 2007 - 9:41 PM

Coomer I ended up coming home last night, so I wasn't... Feb 19, 2007 - 9:41 PM

playr158 looking good coomer

but actually the 2 sized velo... Feb 19, 2007 - 10:32 PM

playr158 looking good coomer

but actually the 2 sized velo... Feb 19, 2007 - 10:32 PM

Coomer Last night I made some good progress.

I removed ... Feb 24, 2007 - 3:54 PM

Coomer Last night I made some good progress.

I removed ... Feb 24, 2007 - 3:54 PM

97lestyousay QUOTE(Coomer @ Feb 24, 2007 - 12:54 ... Feb 24, 2007 - 4:36 PM

97lestyousay QUOTE(Coomer @ Feb 24, 2007 - 12:54 ... Feb 24, 2007 - 4:36 PM

celicast3sgte nice work man Feb 24, 2007 - 6:05 PM

celicast3sgte nice work man Feb 24, 2007 - 6:05 PM

Bigmeanbulldog55 Nice progress, as usual Coomer. btw, what's s... Feb 24, 2007 - 8:18 PM

Bigmeanbulldog55 Nice progress, as usual Coomer. btw, what's s... Feb 24, 2007 - 8:18 PM

Coomer QUOTE(Bigmeanbulldog55 @ Feb 24, 2007 - ... Feb 24, 2007 - 8:31 PM

Coomer QUOTE(Bigmeanbulldog55 @ Feb 24, 2007 - ... Feb 24, 2007 - 8:31 PM

97lestyousay QUOTE(Bigmeanbulldog55 @ Feb 24, 2007 - ... Feb 24, 2007 - 10:26 PM

97lestyousay QUOTE(Bigmeanbulldog55 @ Feb 24, 2007 - ... Feb 24, 2007 - 10:26 PM

Bitter no more teef on em :lol: Feb 24, 2007 - 9:28 PM

Bitter no more teef on em :lol: Feb 24, 2007 - 9:28 PM

Drew-887 What trans do you plan on using if the C52 is junk... Feb 26, 2007 - 12:54 AM

Drew-887 What trans do you plan on using if the C52 is junk... Feb 26, 2007 - 12:54 AM

lagos coomer looks WAY to clean for having just worked o... Feb 26, 2007 - 12:59 AM

lagos coomer looks WAY to clean for having just worked o... Feb 26, 2007 - 12:59 AM

95CelicaST QUOTE

I have that sweatshirt... well jacket..... Feb 28, 2007 - 5:12 PM

95CelicaST QUOTE

I have that sweatshirt... well jacket..... Feb 28, 2007 - 5:12 PM

Coomer QUOTE(Drew-887 @ Feb 25, 2007 - 9... Feb 26, 2007 - 1:02 AM

Coomer QUOTE(Drew-887 @ Feb 25, 2007 - 9... Feb 26, 2007 - 1:02 AM

Coomer Today in class I was bored, so I drew up my basic ... Feb 28, 2007 - 4:34 PM

Coomer Today in class I was bored, so I drew up my basic ... Feb 28, 2007 - 4:34 PM

Bigmeanbulldog55 ^^You're a pretty big dork, man. Good job on ... Feb 28, 2007 - 5:01 PM

Bigmeanbulldog55 ^^You're a pretty big dork, man. Good job on ... Feb 28, 2007 - 5:01 PM

hitcachi Hey Chris, I havent been on the site in awhile, an... Feb 28, 2007 - 5:09 PM

hitcachi Hey Chris, I havent been on the site in awhile, an... Feb 28, 2007 - 5:09 PM

Coomer QUOTE(Bigmeanbulldog55 @ Feb 28, 2007 - ... Feb 28, 2007 - 6:00 PM

Coomer QUOTE(Bigmeanbulldog55 @ Feb 28, 2007 - ... Feb 28, 2007 - 6:00 PM

Coomer Tonight all I really got done was getting the dash... Mar 1, 2007 - 5:50 AM

Coomer Tonight all I really got done was getting the dash... Mar 1, 2007 - 5:50 AM

Bitter looks like the clutch springs all hit something, a... Mar 1, 2007 - 8:30 AM

Bitter looks like the clutch springs all hit something, a... Mar 1, 2007 - 8:30 AM

WannabeGT4 I had a problem like that with the clutch in my tu... Mar 1, 2007 - 9:29 AM

WannabeGT4 I had a problem like that with the clutch in my tu... Mar 1, 2007 - 9:29 AM

playr158 the A/C unit comes out pretty easily....

bolts on... Mar 1, 2007 - 10:22 AM

playr158 the A/C unit comes out pretty easily....

bolts on... Mar 1, 2007 - 10:22 AM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 30th, 2024 - 12:24 PM |