Mar 27, 2008 - 9:29 AM Mar 27, 2008 - 9:29 AM

|

|

|

Enthusiast   Joined Mar 27, '08 From newport news, va Currently Offline Reputation: 2 (100%) |

for valve covers

10 VC's - $65/ea 15VC's - $55/ea if we get more than 20 I will reduce the price further and so on. edit: this group buy is being held to further expand our business to serve you. better equipment means faster turnaround times and more productivity http://www.gsspowdercoating.com/ pics can also be found here: http://www.mr2.com/forums/gi_shu_som-powde...ure-thread.html Valve covers: 1. 5vzbound - lollipop blue over chrome, PAID, SHIPPED BACK 2. 5vzbound - lollipop blue over chrome, PAID, SHIPPED BACK 3. tycoon788 - Psycho Lime, PAID, SHIPPED BACK 4. 2restomod - brushed chrome w/swb letters, PAID, SHIPPED BACK 5. 2restomod -brushed chrome w/swb letters, PAID, SHIPPED BACK 6. oscatr_hk 7. Ek9Max 8. 94celicadude - super wet black, PAID, SHIPPED BACK "AGAIN" 9. colonel - Lollypop red, PAID, SHIPPED BACK 10. CelicaGT96 - silver vein mettalic, PAID, SHIPPED BACK 11. 6gsillyca - wrinkle black w/ candy gold lettering, PAID, SHIPPED BACK 12. mr2dude - speckled sun gold, "pending customs (german customer) 13. snapshotgt - pastel dark brass, PAID, SHIPPED BACK This post has been edited by jazzcornet: May 13, 2008 - 7:52 PM -------------------- |

|

Replies

Apr 17, 2008 - 6:18 PM Apr 17, 2008 - 6:18 PM

|

|

|

Enthusiast   Joined Mar 27, '08 From newport news, va Currently Offline Reputation: 2 (100%) |

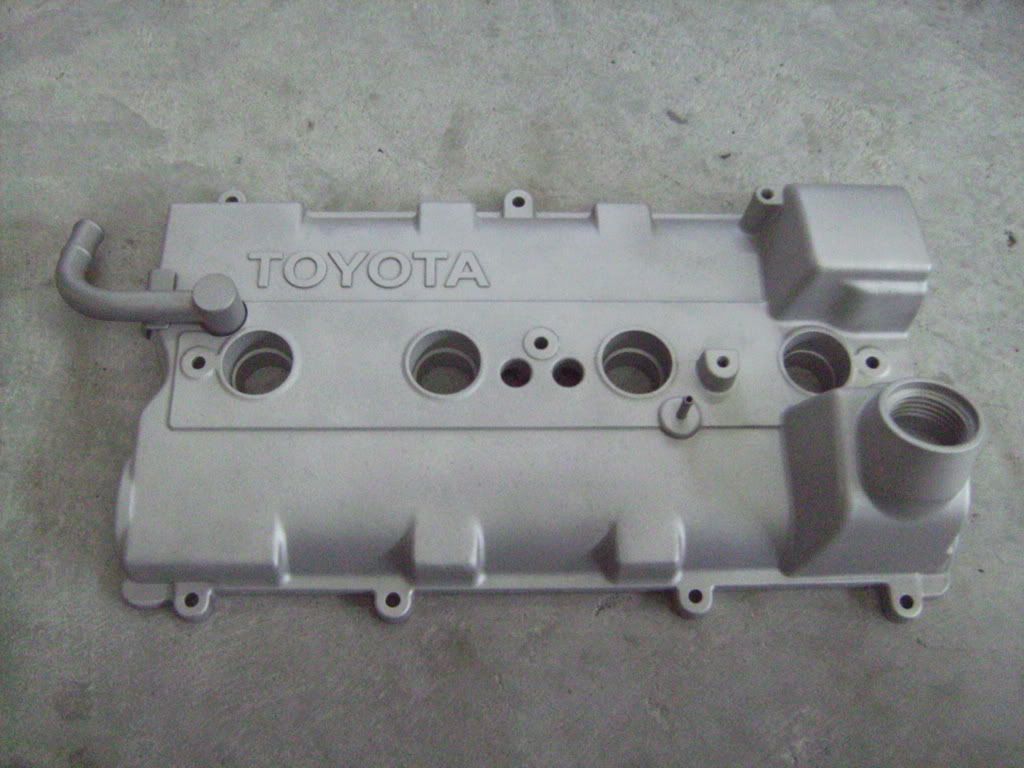

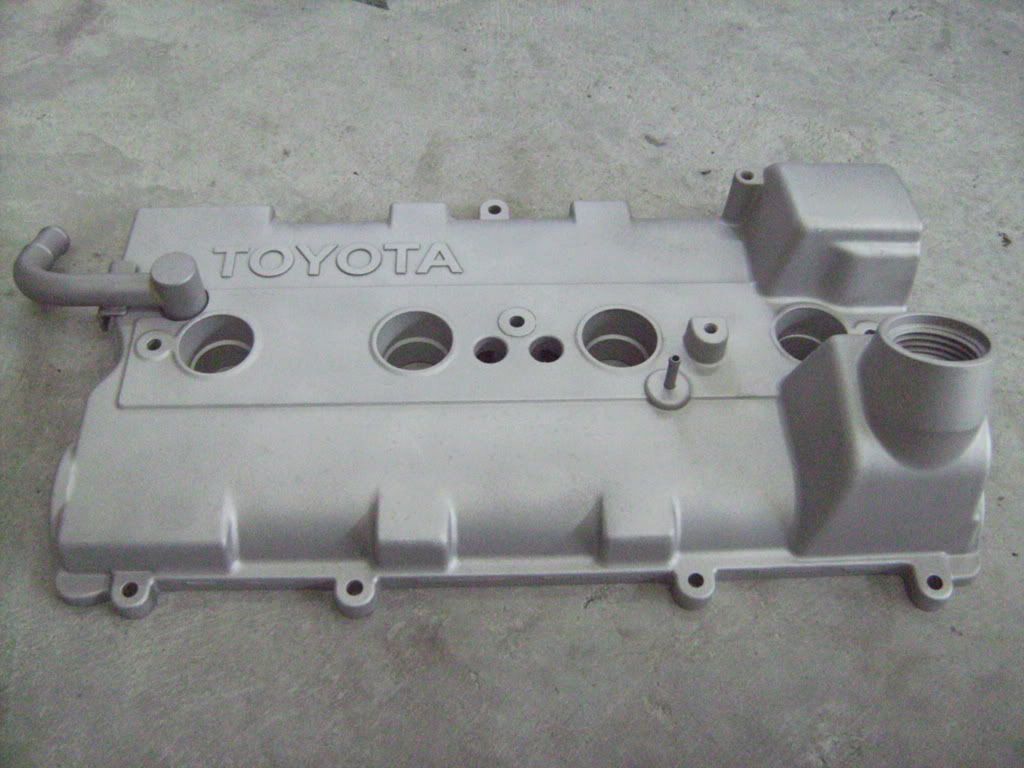

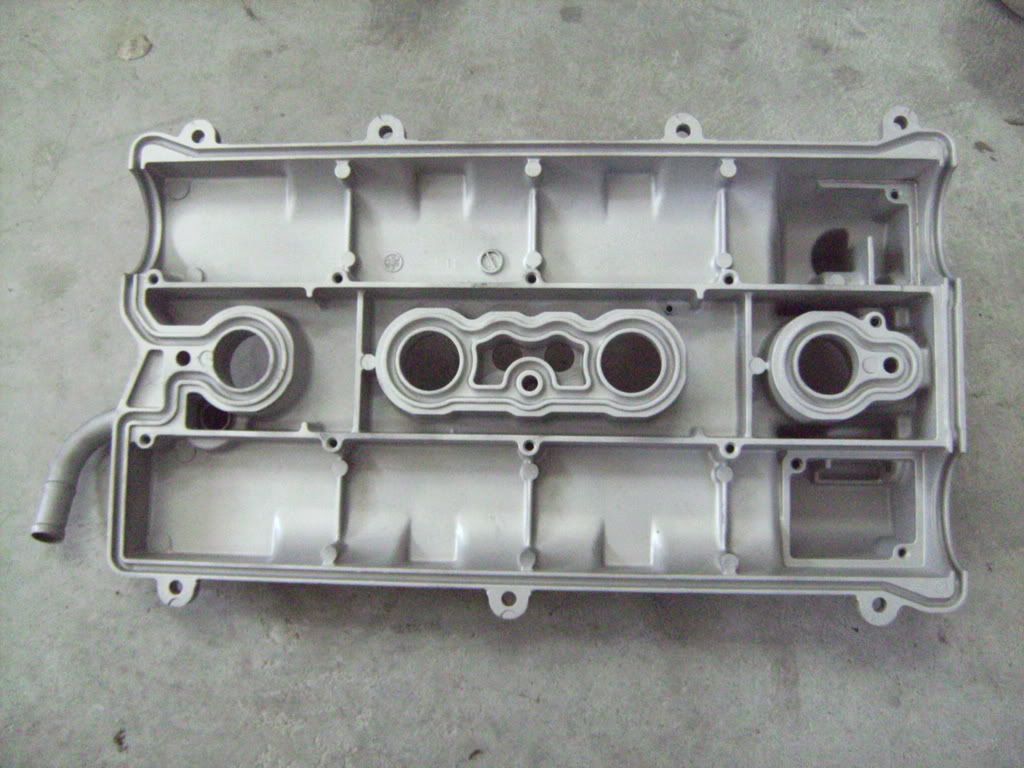

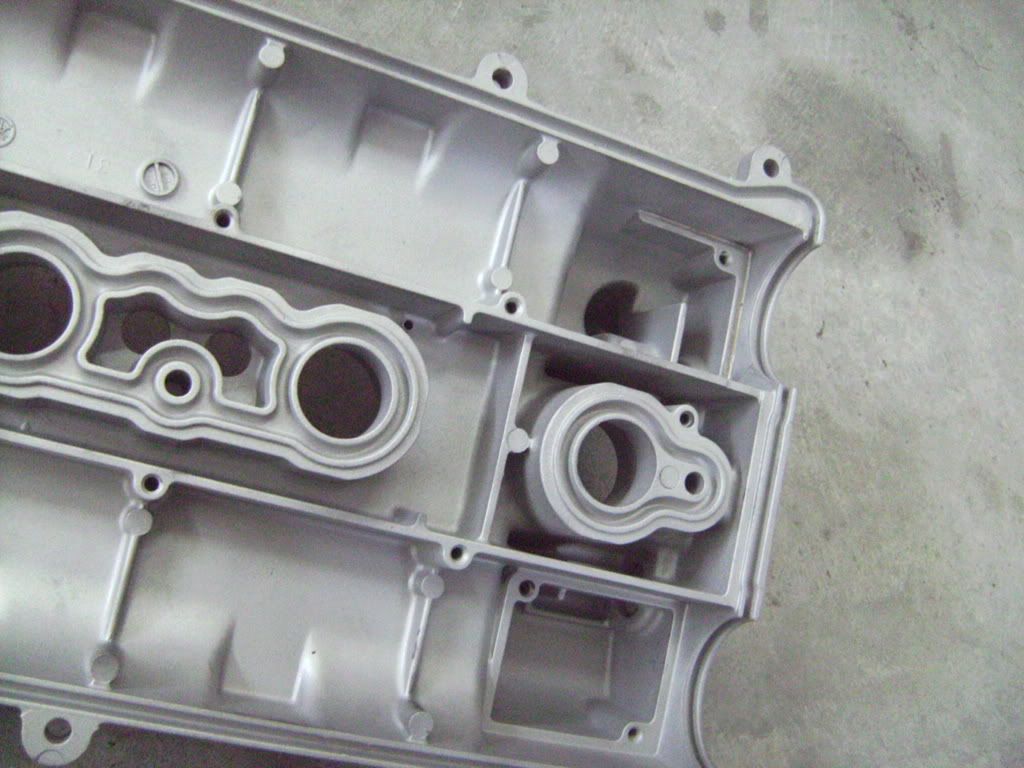

and since everyone has been asking about the prep work that we do. here's a start.

first we start with a hot tank degreasing. it's nothing more than a ratio of purple power degreaser and water heated up to 140 degrees farenheit. we let it soak in there for about an hour. then, we remove the oil baffles and let the baffle plates soak longer while we blast the valve covers. we first blast it with 15/30 grit silicone carbide which removes all the greasy and brutal gunk that has been soaking on it for the last 16 years. this is followed by a 70 grit aluminum oxide and finally a 300 grit glass bead. at this point. if the substrate still has impurities of really bad pitting, we may or may not go back to square one and start with files and/or a power sander. after the sanding, we rince it off with water and blow it dry with clean compressed air. once it is completely dry, we outgas it at 500 degrees for 90 minutes. before we give it a chance to cool off, we spray it with denatured alchohol and let it evaporate dry. the substrate is now ready for powder. here are some pics of a valve cover after prep and ready for powder!

-------------------- |

Posts in this topic

jazzcornet Powdercoating Services Groupbuy Mar 27, 2008 - 9:29 AM

jazzcornet Powdercoating Services Groupbuy Mar 27, 2008 - 9:29 AM

presure2 stickied.

JC, i edited in a link to your site, an... Mar 27, 2008 - 9:40 AM

presure2 stickied.

JC, i edited in a link to your site, an... Mar 27, 2008 - 9:40 AM

goferris i would possibly be interested in a VC job in Red ... Mar 27, 2008 - 9:52 AM

goferris i would possibly be interested in a VC job in Red ... Mar 27, 2008 - 9:52 AM

95CelicaST Too bad powdercoating the VC's on my Subaru wo... Mar 27, 2008 - 9:53 AM

95CelicaST Too bad powdercoating the VC's on my Subaru wo... Mar 27, 2008 - 9:53 AM

presure2 this is not a "i can get it cheaper here..... Mar 27, 2008 - 10:37 AM

presure2 this is not a "i can get it cheaper here..... Mar 27, 2008 - 10:37 AM

Tigawoods resume is outstanding. i will take a look in the ... Mar 27, 2008 - 11:14 AM

Tigawoods resume is outstanding. i will take a look in the ... Mar 27, 2008 - 11:14 AM

illneversellmycelli yep i cant wait to get it done I hope the GB is a ... Mar 27, 2008 - 12:22 PM

illneversellmycelli yep i cant wait to get it done I hope the GB is a ... Mar 27, 2008 - 12:22 PM

jazzcornet ironically enough, we probably have the cheapest p... Mar 27, 2008 - 3:29 PM

jazzcornet ironically enough, we probably have the cheapest p... Mar 27, 2008 - 3:29 PM

bseaman_5 QUOTE(jazzcornet @ Mar 27, 2008 - 3... Apr 14, 2008 - 12:26 PM

bseaman_5 QUOTE(jazzcornet @ Mar 27, 2008 - 3... Apr 14, 2008 - 12:26 PM

jazzcornet presure2

I dont know how things work around here ... Mar 27, 2008 - 11:04 PM

jazzcornet presure2

I dont know how things work around here ... Mar 27, 2008 - 11:04 PM

presure2 QUOTE(jazzcornet @ Mar 28, 2008 - 12... Mar 28, 2008 - 5:37 PM

presure2 QUOTE(jazzcornet @ Mar 28, 2008 - 12... Mar 28, 2008 - 5:37 PM

palooke Awesome so can anyone else join? Mar 28, 2008 - 6:05 PM

palooke Awesome so can anyone else join? Mar 28, 2008 - 6:05 PM

politicsareevil I know this will sound horrible... I used to work ... Mar 27, 2008 - 11:15 PM

politicsareevil I know this will sound horrible... I used to work ... Mar 27, 2008 - 11:15 PM

6gsillyca What would shipping costs be to Canada? Do you do ... Mar 28, 2008 - 12:58 AM

6gsillyca What would shipping costs be to Canada? Do you do ... Mar 28, 2008 - 12:58 AM

illneversellmycelli yes he does check out the pics link in the top of ... Mar 28, 2008 - 8:18 AM

illneversellmycelli yes he does check out the pics link in the top of ... Mar 28, 2008 - 8:18 AM

jazzcornet the color you are reffering to is wrinkle red. my ... Mar 28, 2008 - 9:08 AM

jazzcornet the color you are reffering to is wrinkle red. my ... Mar 28, 2008 - 9:08 AM

spolski07 how long is the turn around?

id want to get my VC,... Mar 28, 2008 - 9:14 AM

spolski07 how long is the turn around?

id want to get my VC,... Mar 28, 2008 - 9:14 AM

jazzcornet turn around time would be no more than 72hours. gu... Mar 28, 2008 - 10:37 AM

jazzcornet turn around time would be no more than 72hours. gu... Mar 28, 2008 - 10:37 AM

jazzcornet everyone is welcome for any of my services. the gr... Mar 28, 2008 - 6:52 PM

jazzcornet everyone is welcome for any of my services. the gr... Mar 28, 2008 - 6:52 PM

goferris does anyone have an extra VC for a 5sfe that i can... Mar 28, 2008 - 7:05 PM

goferris does anyone have an extra VC for a 5sfe that i can... Mar 28, 2008 - 7:05 PM

politicsareevil QUOTE(goferris @ Mar 28, 2008 - 5:05... Mar 28, 2008 - 8:02 PM

politicsareevil QUOTE(goferris @ Mar 28, 2008 - 5:05... Mar 28, 2008 - 8:02 PM

jazzcornet goferris and politicsareevil

i can setup a core c... Mar 28, 2008 - 9:30 PM

jazzcornet goferris and politicsareevil

i can setup a core c... Mar 28, 2008 - 9:30 PM

presure2 QUOTE(jazzcornet @ Mar 28, 2008 - 10... Mar 28, 2008 - 9:36 PM

presure2 QUOTE(jazzcornet @ Mar 28, 2008 - 10... Mar 28, 2008 - 9:36 PM

goferris QUOTE(jazzcornet @ Mar 28, 2008 - 8... Mar 28, 2008 - 10:30 PM

goferris QUOTE(jazzcornet @ Mar 28, 2008 - 8... Mar 28, 2008 - 10:30 PM

6gsillyca QUOTE(jazzcornet @ Mar 28, 2008 - 8... Mar 28, 2008 - 11:53 PM

6gsillyca QUOTE(jazzcornet @ Mar 28, 2008 - 8... Mar 28, 2008 - 11:53 PM

jazzcornet pics? i thought a 3s was a 3s with the exception o... Mar 28, 2008 - 9:47 PM

jazzcornet pics? i thought a 3s was a 3s with the exception o... Mar 28, 2008 - 9:47 PM

jazzcornet all colors that we offer are included in this grou... Mar 29, 2008 - 4:40 PM

jazzcornet all colors that we offer are included in this grou... Mar 29, 2008 - 4:40 PM

95st-celica would you be able to match the exact color of my c... Mar 29, 2008 - 8:10 PM

95st-celica would you be able to match the exact color of my c... Mar 29, 2008 - 8:10 PM

jazzcornet i wouldn't be able to perfectly match it. but ... Mar 29, 2008 - 9:07 PM

jazzcornet i wouldn't be able to perfectly match it. but ... Mar 29, 2008 - 9:07 PM

supershannon77 If core exchange was set up put me down for two...... Mar 29, 2008 - 9:14 PM

supershannon77 If core exchange was set up put me down for two...... Mar 29, 2008 - 9:14 PM

jazzcornet im working on it. but i've been told the 5s VC... Mar 29, 2008 - 9:33 PM

jazzcornet im working on it. but i've been told the 5s VC... Mar 29, 2008 - 9:33 PM

presure2 QUOTE(jazzcornet @ Mar 29, 2008 - 10... Mar 30, 2008 - 7:35 AM

presure2 QUOTE(jazzcornet @ Mar 29, 2008 - 10... Mar 30, 2008 - 7:35 AM

jazzcornet thank you. Mar 30, 2008 - 4:49 PM

jazzcornet thank you. Mar 30, 2008 - 4:49 PM

CelicaST_CALI how much would it be to chrome a valve cover and i... Mar 30, 2008 - 7:14 PM

CelicaST_CALI how much would it be to chrome a valve cover and i... Mar 30, 2008 - 7:14 PM

jazzcornet chrome plate or chrome powdercoat??

if you get in... Mar 30, 2008 - 7:54 PM

jazzcornet chrome plate or chrome powdercoat??

if you get in... Mar 30, 2008 - 7:54 PM

CelicaST_CALI i have a 7afe,y would the intake manifold be more ... Mar 30, 2008 - 8:01 PM

CelicaST_CALI i have a 7afe,y would the intake manifold be more ... Mar 30, 2008 - 8:01 PM

jazzcornet thanks for the pic

the IM has much more coatable ... Mar 30, 2008 - 8:14 PM

jazzcornet thanks for the pic

the IM has much more coatable ... Mar 30, 2008 - 8:14 PM

jazzcornet ttt Mar 31, 2008 - 9:26 AM

jazzcornet ttt Mar 31, 2008 - 9:26 AM

illneversellmycelli bump bump bump!

that chrome looks awesome, bu... Apr 1, 2008 - 7:20 AM

illneversellmycelli bump bump bump!

that chrome looks awesome, bu... Apr 1, 2008 - 7:20 AM

jazzcornet nope. chrome plating turns colors when it heats up... Apr 1, 2008 - 8:41 AM

jazzcornet nope. chrome plating turns colors when it heats up... Apr 1, 2008 - 8:41 AM

illneversellmycelli sweet after the vc get done ill probaly have you c... Apr 1, 2008 - 1:47 PM

illneversellmycelli sweet after the vc get done ill probaly have you c... Apr 1, 2008 - 1:47 PM

jazzcornet sounds good!! Apr 1, 2008 - 3:11 PM

jazzcornet sounds good!! Apr 1, 2008 - 3:11 PM

jazzcornet OP edited Apr 1, 2008 - 7:55 PM

jazzcornet OP edited Apr 1, 2008 - 7:55 PM

jazzcornet only three more people are needed to make this off... Apr 1, 2008 - 10:59 PM

jazzcornet only three more people are needed to make this off... Apr 1, 2008 - 10:59 PM

jazzcornet [QUOTE=politicsareevil}haha x2 but For me its... d... Apr 2, 2008 - 11:34 PM

jazzcornet [QUOTE=politicsareevil}haha x2 but For me its... d... Apr 2, 2008 - 11:34 PM

jazzcornet we only need two more Apr 4, 2008 - 8:02 AM

jazzcornet we only need two more Apr 4, 2008 - 8:02 AM

jazzcornet only one more to go and we have ourselves a group ... Apr 5, 2008 - 3:17 PM

jazzcornet only one more to go and we have ourselves a group ... Apr 5, 2008 - 3:17 PM

celicaGT96 count me in!!

i just need to decide what ... Apr 5, 2008 - 3:24 PM

celicaGT96 count me in!!

i just need to decide what ... Apr 5, 2008 - 3:24 PM

jazzcornet there you have it. we have ourselves a group buy... Apr 5, 2008 - 3:36 PM

jazzcornet there you have it. we have ourselves a group buy... Apr 5, 2008 - 3:36 PM

jazzcornet OP updated Apr 7, 2008 - 10:23 AM

jazzcornet OP updated Apr 7, 2008 - 10:23 AM

illneversellmycelli bump 4 more people and i save 20 bucks lol Apr 7, 2008 - 12:48 PM

illneversellmycelli bump 4 more people and i save 20 bucks lol Apr 7, 2008 - 12:48 PM

jazzcornet quite possibly only one more person. just had a PM... Apr 7, 2008 - 1:24 PM

jazzcornet quite possibly only one more person. just had a PM... Apr 7, 2008 - 1:24 PM

jazzcornet dont know if anyone is interested, but i also have... Apr 7, 2008 - 11:16 PM

jazzcornet dont know if anyone is interested, but i also have... Apr 7, 2008 - 11:16 PM

CAMAricer Hi, a couple of questions:

1) Will/can you paint ... Apr 7, 2008 - 11:55 PM

CAMAricer Hi, a couple of questions:

1) Will/can you paint ... Apr 7, 2008 - 11:55 PM

jazzcornet strut bars usually run from $55 and up. depen... Apr 8, 2008 - 9:04 AM

jazzcornet strut bars usually run from $55 and up. depen... Apr 8, 2008 - 9:04 AM

CAMAricer Cool. Let me see if my bro wants in on this, he... Apr 8, 2008 - 9:25 AM

CAMAricer Cool. Let me see if my bro wants in on this, he... Apr 8, 2008 - 9:25 AM

JoKeRkId613 havent read the whole thread but do you powdercoat... Apr 8, 2008 - 9:58 AM

JoKeRkId613 havent read the whole thread but do you powdercoat... Apr 8, 2008 - 9:58 AM

jazzcornet calipers i can do as well. be sure to send them co... Apr 8, 2008 - 1:58 PM

jazzcornet calipers i can do as well. be sure to send them co... Apr 8, 2008 - 1:58 PM

JoKeRkId613 QUOTE(jazzcornet @ Apr 8, 2008 - 2:5... Apr 14, 2008 - 11:53 AM

JoKeRkId613 QUOTE(jazzcornet @ Apr 8, 2008 - 2:5... Apr 14, 2008 - 11:53 AM

jazzcornet if your name doesnt have a color listed next to it... Apr 9, 2008 - 12:46 AM

jazzcornet if your name doesnt have a color listed next to it... Apr 9, 2008 - 12:46 AM

6gsillyca I'm in for a 93 3sgte core exchange... Apr 9, 2008 - 10:31 AM

6gsillyca I'm in for a 93 3sgte core exchange... Apr 9, 2008 - 10:31 AM

jazzcornet 6gsillyca....

you have been added to the list. yo... Apr 9, 2008 - 2:26 PM

jazzcornet 6gsillyca....

you have been added to the list. yo... Apr 9, 2008 - 2:26 PM

njccmd2002 QUOTE(jazzcornet @ Apr 9, 2008 - 3:2... Apr 18, 2008 - 7:09 PM

njccmd2002 QUOTE(jazzcornet @ Apr 9, 2008 - 3:2... Apr 18, 2008 - 7:09 PM

jazzcornet parts received from colonel, tycoon, and matt ezra Apr 10, 2008 - 8:31 AM

jazzcornet parts received from colonel, tycoon, and matt ezra Apr 10, 2008 - 8:31 AM

illneversellmycelli Valve covers:

1. 5vzbound lollipop blue over chrom... Apr 10, 2008 - 9:43 AM

illneversellmycelli Valve covers:

1. 5vzbound lollipop blue over chrom... Apr 10, 2008 - 9:43 AM

snapshotgt Please add me to the list. Apr 10, 2008 - 7:16 PM

snapshotgt Please add me to the list. Apr 10, 2008 - 7:16 PM

jazzcornet added. please let me know what color you would lik... Apr 11, 2008 - 9:27 AM

jazzcornet added. please let me know what color you would lik... Apr 11, 2008 - 9:27 AM

jazzcornet only one more day on this group buy. get your orde... Apr 14, 2008 - 12:07 AM

jazzcornet only one more day on this group buy. get your orde... Apr 14, 2008 - 12:07 AM

celicadude04 Can you powdercoat headers? Apr 14, 2008 - 8:45 AM

celicadude04 Can you powdercoat headers? Apr 14, 2008 - 8:45 AM

jazzcornet i can ceramic coat headers Apr 14, 2008 - 11:37 AM

jazzcornet i can ceramic coat headers Apr 14, 2008 - 11:37 AM

jazzcornet QUOTE(JoKeRkId613 @ Apr 14, 2008 - 11... Apr 14, 2008 - 1:13 PM

jazzcornet QUOTE(JoKeRkId613 @ Apr 14, 2008 - 11... Apr 14, 2008 - 1:13 PM

politicsareevil Post some pics when you finish some of the VCs ple... Apr 14, 2008 - 8:19 PM

politicsareevil Post some pics when you finish some of the VCs ple... Apr 14, 2008 - 8:19 PM

celicaGT96 QUOTE(politicsareevil @ Apr 14, 2008 - 8... Apr 14, 2008 - 8:25 PM

celicaGT96 QUOTE(politicsareevil @ Apr 14, 2008 - 8... Apr 14, 2008 - 8:25 PM

jazzcornet i most definately will. it will be a part two of t... Apr 14, 2008 - 8:30 PM

jazzcornet i most definately will. it will be a part two of t... Apr 14, 2008 - 8:30 PM

jazzcornet this group buy is now officially closed. all order... Apr 15, 2008 - 2:12 AM

jazzcornet this group buy is now officially closed. all order... Apr 15, 2008 - 2:12 AM

jazzcornet results of the group buy start here.

5vzbound - p... Apr 16, 2008 - 8:40 PM

jazzcornet results of the group buy start here.

5vzbound - p... Apr 16, 2008 - 8:40 PM

celicaGT96 wow im very impressed with your work. im also very... Apr 17, 2008 - 8:42 PM

celicaGT96 wow im very impressed with your work. im also very... Apr 17, 2008 - 8:42 PM

jazzcornet just between yo uand me (and apparently everyone e... Apr 17, 2008 - 10:06 PM

jazzcornet just between yo uand me (and apparently everyone e... Apr 17, 2008 - 10:06 PM

jazzcornet matt, i need your shipping address. i cant find th... Apr 17, 2008 - 10:11 PM

jazzcornet matt, i need your shipping address. i cant find th... Apr 17, 2008 - 10:11 PM

celicaGT96 oh ok so itll be a different cover? as long as its... Apr 18, 2008 - 11:45 AM

celicaGT96 oh ok so itll be a different cover? as long as its... Apr 18, 2008 - 11:45 AM

jazzcornet yep. same genIII valve cover just not specifically... Apr 18, 2008 - 1:00 PM

jazzcornet yep. same genIII valve cover just not specifically... Apr 18, 2008 - 1:00 PM

jazzcornet cleaning is included Apr 18, 2008 - 7:41 PM

jazzcornet cleaning is included Apr 18, 2008 - 7:41 PM

jazzcornet RE: Powdercoating Services Groupbuy Apr 22, 2008 - 4:02 PM

jazzcornet RE: Powdercoating Services Groupbuy Apr 22, 2008 - 4:02 PM

jazzcornet RE: Powdercoating Services Groupbuy Apr 22, 2008 - 4:18 PM

jazzcornet RE: Powdercoating Services Groupbuy Apr 22, 2008 - 4:18 PM

GriffGirl holy crap that stuff looks amazing. If and when I ... Apr 22, 2008 - 4:25 PM

GriffGirl holy crap that stuff looks amazing. If and when I ... Apr 22, 2008 - 4:25 PM

jazzcornet what engine do you have? i have a few cores laying... Apr 22, 2008 - 4:48 PM

jazzcornet what engine do you have? i have a few cores laying... Apr 22, 2008 - 4:48 PM

JoKeRkId613 do you happen to have scion tc calipers laying aro... Apr 22, 2008 - 5:15 PM

JoKeRkId613 do you happen to have scion tc calipers laying aro... Apr 22, 2008 - 5:15 PM

jazzcornet sorry, but most of my stock is for MR2's and s... Apr 22, 2008 - 5:40 PM

jazzcornet sorry, but most of my stock is for MR2's and s... Apr 22, 2008 - 5:40 PM

jazzcornet pressure2...

how do i go about becoming a sponsor... Apr 22, 2008 - 6:46 PM

jazzcornet pressure2...

how do i go about becoming a sponsor... Apr 22, 2008 - 6:46 PM

supershannon77 whats the cost on having the turbo done? Apr 22, 2008 - 6:52 PM

supershannon77 whats the cost on having the turbo done? Apr 22, 2008 - 6:52 PM

jazzcornet it really depends on the specific turbo and the co... Apr 23, 2008 - 10:20 PM

jazzcornet it really depends on the specific turbo and the co... Apr 23, 2008 - 10:20 PM

jazzcornet wrinkle black 93+ 3sgte mr2 valve cover.

sorry ab... Apr 30, 2008 - 6:55 PM

jazzcornet wrinkle black 93+ 3sgte mr2 valve cover.

sorry ab... Apr 30, 2008 - 6:55 PM

njccmd2002 Like that color, so much. so what is the going r... Apr 30, 2008 - 8:57 PM

njccmd2002 Like that color, so much. so what is the going r... Apr 30, 2008 - 8:57 PM

jazzcornet the group buy has ended for the valve covers. now ... Apr 30, 2008 - 9:13 PM

jazzcornet the group buy has ended for the valve covers. now ... Apr 30, 2008 - 9:13 PM

njccmd2002 oh, man ill wait for another GB. thanks.. Apr 30, 2008 - 9:42 PM

njccmd2002 oh, man ill wait for another GB. thanks.. Apr 30, 2008 - 9:42 PM

CAMAricer Dang, missed the GB. Finally got my parts but now... May 1, 2008 - 12:28 AM

CAMAricer Dang, missed the GB. Finally got my parts but now... May 1, 2008 - 12:28 AM

jazzcornet tracking to Mr. Mah in Calgary Alberta

CJ 169 51... May 1, 2008 - 6:39 PM

jazzcornet tracking to Mr. Mah in Calgary Alberta

CJ 169 51... May 1, 2008 - 6:39 PM

jazzcornet here is the lollypop blue 5vz valve covers and the... May 4, 2008 - 4:20 PM

jazzcornet here is the lollypop blue 5vz valve covers and the... May 4, 2008 - 4:20 PM

snapshotgt QUOTE(jazzcornet @ May 4, 2008 - 4:2... May 4, 2008 - 7:13 PM

snapshotgt QUOTE(jazzcornet @ May 4, 2008 - 4:2... May 4, 2008 - 7:13 PM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: April 23rd, 2025 - 5:58 PM |