Aug 26, 2008 - 10:30 PM Aug 26, 2008 - 10:30 PM

|

|

Enthusiast      Joined Mar 8, '04 From Newport, RI Currently Offline Reputation: 63 (99%) |

First off I got a good deal on a st205 engine set (basically everything from a clip) and I bought everything I would need to freshen it up. Then I picked up a low mileage e153 (from a 2000 Camry) and MR2 turbo inners and all-trac outers.

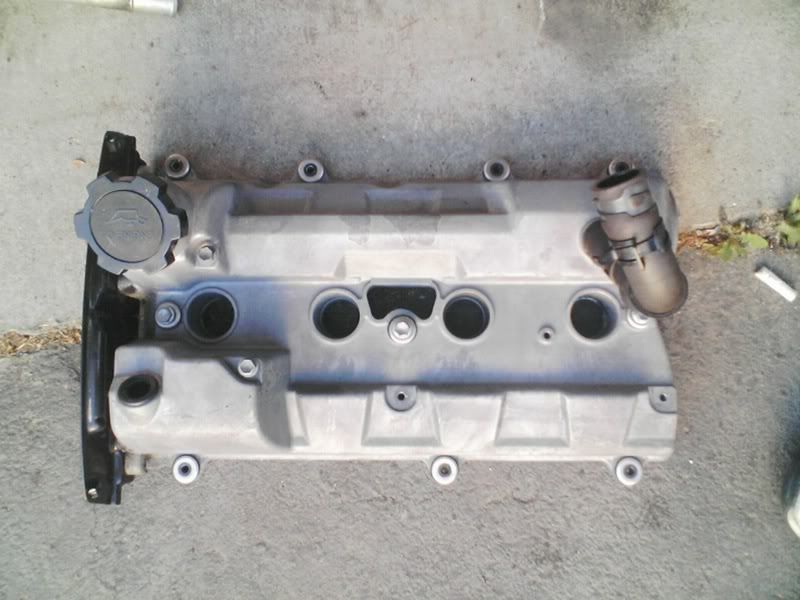

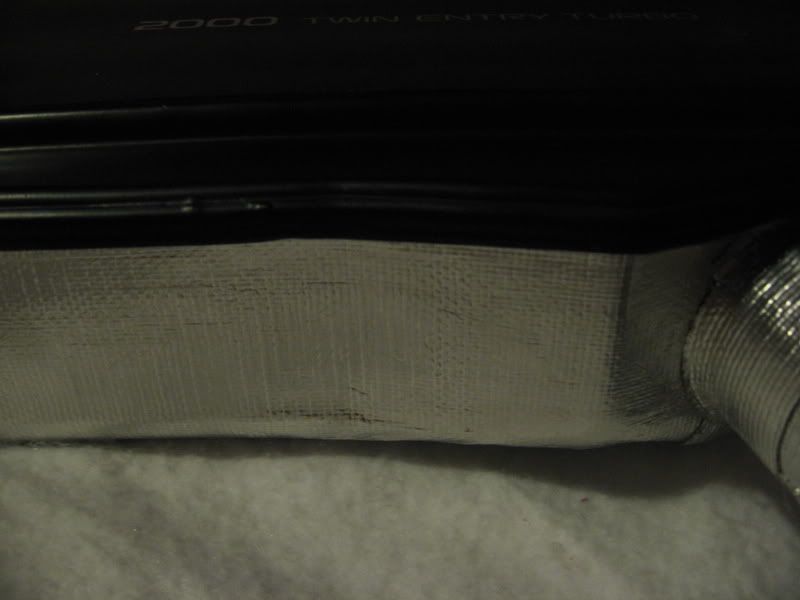

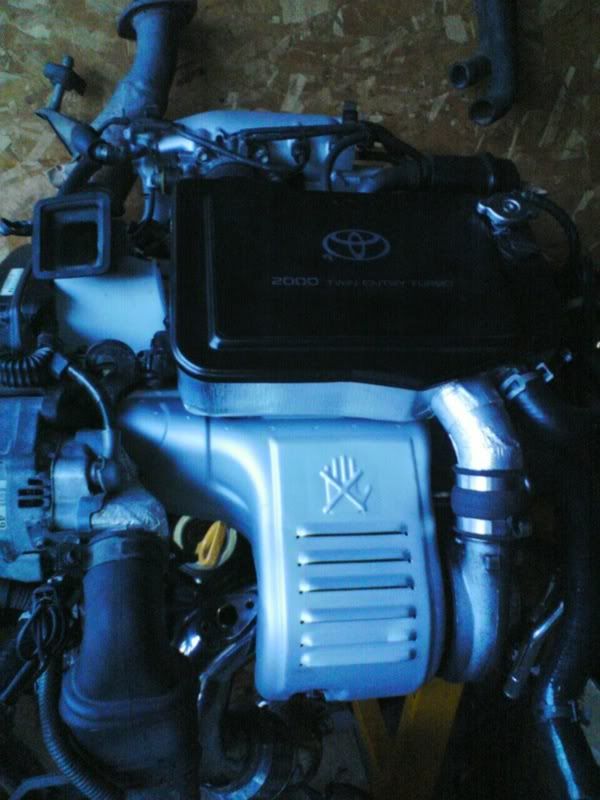

pics from the day I got the engine       ^^ Manny (presure2) was pretty excited then we did some things to the motor    ^^ what a mess  mmm clean the valve cover, heat shield, and intake manifold we coated with a high temp ceramic coating (no pics) and I lagged the IC with this, thermo-tech the "lagging" is an adhesive backed aluminized heat barrier which will reduce heat soak with the IC.     cleaned it out and this is what I'm running it in.  then axle madness began first, 2 sets  then one set  spacer    and spare parts  I then did the wire harness so it would be plug and play for the car. I first wired in a seperat relay box for the IC and fuel pump relays but after I swaped I rewired it to the stock st205 FP and IC replay box, pics later. not the best pic of the motor but something  then the st205 front end went on (see the 3s in the backround)  I really didn't take too many pics of things because every time I was with the motor, I was doing something to make the swap easier. then the fun began Friday night - day one     remove motor, clean bay, remove battery tray put in IC pump    and with st205 puke tank  I'm tired   Saturday - day two extend the wire harness ? hell no. Cut a hole in the firwall and put harness through.  played with new e153 tranny, clutch, attach to motor and put in car   Sunday - day three - the exhaust. I already have a HKS cat-back so Manny made a b pipe - from the berk dp to the HKS. started with this  and it became...  tacked and almost finished  done and a quick paint job (that got a little scratched when installed). Manny says "I stand by my exhaust"  and a few installed   and the exhaust cut out from Q T P  I have 3" from the turbo to the cat-back (which is 2.5") so as Corey did we installed a butterfly open exhaust valve. I put in a toggle switch so I can open and close the butterfly whenever I want. Quiet cruising with it closed and all the exhaust goes out the back OR I open it up, it gets loud and free flowing exhaust - no restriction put on a new "2000 twin entry turbo" sticker and done for that day. BTW it started and purred like a CHAMP ! FIRST TRY !!!!!!!!!!!!!111!!!!!1!!! The car runs great and feels INCREDIBLE. Now I have had a couple of (expected) problems. The freakin axles. First, driver's side axle just popped out on a test drive, car towed back to Mannys. next day, have the axle machined to fit in the tranny and added a 1/2 spacer, good as new. then on the second test drive the pass side axle popped out. Car towed back to Mannys. The axle carrier came off the block - the bolts weren't tightened down enough. Sorted that tonight and now it runs perfect, hits boost very well but I think the carrier bearing is bad or the pass side axle is just plain bad. I hear a bit of noise from that side and I think I need another all-trac axle (I think I know where I'll be getting that from) and I'll rebiuld it again. And that's where I'm at right now. The place all the majic happened was presure2's (Manny) garage and I had some help from Manny & Jenn, my woman Stef (hurley97), and Manny's cousin Joey. A small "pit crew" how each did their thing to help me. I'll take and post up some finished pics tomorrow night or so, I've had a stressful and busy 4-5 days. This post has been edited by Batman722: Mar 22, 2009 - 6:43 PM -------------------- |

|

Replies

Sep 18, 2008 - 9:56 PM Sep 18, 2008 - 9:56 PM

|

|

Enthusiast      Joined Mar 8, '04 From Newport, RI Currently Offline Reputation: 63 (99%) |

i'm curious to know where exactly on the firewall you cut to fit the engine harness? did you use the same rubber grommet from the original harness on the firewall?  ^^ that's the only pic I have. I first decided what spot would be best with the harness, where the ECU sits, and it's a clean spot through the firewall so everything fits nice. We then drilled a hole then measured the size of the sock hole and cut the hole to match. I have the stock rubber grommet over (not screwed in) the hole just like the original spot, just haven't gotten to securing it properly. note: we used the 5s ECU brackets on the 3s ECU to fit it exactly where the 5s one was. Please tell me what you have done regarding the axle's. I too will be useing the same gearbox as you - E153. What I want to know is as the output drives of the E153 gearbox is bigger than that of the S series box, did you just change the inner CV joints of the ST205 to the standard axles of the GT. for the e153, the axles you need are MR2 inner axle stubs (they fit into the tranny) and they bolt onto st185 outer axles (they fit into the celica hubs). Both MR2 and st185 axles are not like the stock celica axles, they each seperate into 2 pieces and and you need inners from one and outers from the other. I also used 1/2inch (12-13mm) spacers in between each piece so they would be long enough for our cars. Snapshotgt posted a pic of his spacer (a few posts up) and I posted a pic on page 1. update. I haven't had much time to mess with the car lately but today I rebuilt the pass side axle. I was leaking grease from the spacer (I didn't use new cork gaskets when I first put it together) and the grease eventually just spun out of it. I could hear the axle make a little noise (from the balls and cage) so I had to get this done. I also put the cruise control back in and we tightened up the power steering line that was leaking too (banjo bolt). so now the car runs just fine, no real problems - just the axle I didn't do properly to begin with and a few little things but nothing major, and nothing that prevents me from boosting heavily daily I need to make a vid soon with how much of a difference the exhaust cut-out makes. If I'm in 3rd at about 3k rpms and I floor it the boost builds to about 11 psi and the car is fast. If I open the cut out and do the same thing it instantly builds up to 17 psi and takes off like you wouldn't believe. It's incredible -------------------- |

Posts in this topic

Batman722 Guess what I did this weekend Aug 26, 2008 - 10:30 PM

Batman722 Guess what I did this weekend Aug 26, 2008 - 10:30 PM

808celica RE: Guess what I did this weekend Aug 26, 2008 - 10:38 PM

808celica RE: Guess what I did this weekend Aug 26, 2008 - 10:38 PM

jcaron9gt4 damn, nice work as usual from you guys Aug 26, 2008 - 10:49 PM

jcaron9gt4 damn, nice work as usual from you guys Aug 26, 2008 - 10:49 PM

bccentaur3 Dang!!!! I was wondering what you ... Aug 26, 2008 - 10:52 PM

bccentaur3 Dang!!!! I was wondering what you ... Aug 26, 2008 - 10:52 PM

1bwilson Looks great! I wish I had a JDM guy shop here ... Aug 26, 2008 - 11:25 PM

1bwilson Looks great! I wish I had a JDM guy shop here ... Aug 26, 2008 - 11:25 PM

97lestyousay NIce work guys. someday.... my clip will come in... Aug 26, 2008 - 11:43 PM

97lestyousay NIce work guys. someday.... my clip will come in... Aug 26, 2008 - 11:43 PM

j0e_p3t its threads like these that make me wish i lived o... Aug 27, 2008 - 1:03 AM

j0e_p3t its threads like these that make me wish i lived o... Aug 27, 2008 - 1:03 AM

malpaso you are just unbelievable... amazing work Dustin... Aug 27, 2008 - 1:34 AM

malpaso you are just unbelievable... amazing work Dustin... Aug 27, 2008 - 1:34 AM

purplegt4 my goodness! i was wondering when this would h... Aug 27, 2008 - 1:57 AM

purplegt4 my goodness! i was wondering when this would h... Aug 27, 2008 - 1:57 AM

easternpiro1 living near you guys would make me brave enough to... Aug 27, 2008 - 2:03 AM

easternpiro1 living near you guys would make me brave enough to... Aug 27, 2008 - 2:03 AM

Rusty welcome to the world of 3S-GE/3SGTE, nice swork

... Aug 27, 2008 - 2:11 AM

Rusty welcome to the world of 3S-GE/3SGTE, nice swork

... Aug 27, 2008 - 2:11 AM

manphibian i just to you guys. Aug 27, 2008 - 2:25 AM

manphibian i just to you guys. Aug 27, 2008 - 2:25 AM

presure2 yay! Aug 27, 2008 - 4:08 AM

presure2 yay! Aug 27, 2008 - 4:08 AM

Batman722 I forgot to thank Manny & Jenn, Stef, and Mann... Aug 27, 2008 - 7:21 AM

Batman722 I forgot to thank Manny & Jenn, Stef, and Mann... Aug 27, 2008 - 7:21 AM

RUNNIN-LOW nice nice nice!!!!!!loving... Aug 27, 2008 - 7:36 AM

RUNNIN-LOW nice nice nice!!!!!!loving... Aug 27, 2008 - 7:36 AM

playr158 Holy crapola....you guys are ridiculous!

yet ... Aug 27, 2008 - 8:06 AM

playr158 Holy crapola....you guys are ridiculous!

yet ... Aug 27, 2008 - 8:06 AM

x_itchy_b_x popping out swaps like its your job! (hint hin... Aug 27, 2008 - 9:19 AM

x_itchy_b_x popping out swaps like its your job! (hint hin... Aug 27, 2008 - 9:19 AM

DEATH Freakin sweet. Three reasons -

1. I didn't th... Aug 27, 2008 - 9:37 AM

DEATH Freakin sweet. Three reasons -

1. I didn't th... Aug 27, 2008 - 9:37 AM

Batman722 QUOTE (DEATH @ Aug 27, 2008 - 10:37 ... Aug 27, 2008 - 12:10 PM

Batman722 QUOTE (DEATH @ Aug 27, 2008 - 10:37 ... Aug 27, 2008 - 12:10 PM

97lestyousay That looks so f***en clean. is the ps working stil... Aug 27, 2008 - 12:39 PM

97lestyousay That looks so f***en clean. is the ps working stil... Aug 27, 2008 - 12:39 PM

Batman722 QUOTE (97lestyousay @ Aug 27, 2008 - 1... Aug 27, 2008 - 3:59 PM

Batman722 QUOTE (97lestyousay @ Aug 27, 2008 - 1... Aug 27, 2008 - 3:59 PM

Defgeph QUOTE (97lestyousay @ Aug 27, 2008 - 1... Aug 29, 2008 - 12:33 AM

Defgeph QUOTE (97lestyousay @ Aug 27, 2008 - 1... Aug 29, 2008 - 12:33 AM

lagos 1. Make some videos!

2. Get to the dyno. I a... Aug 27, 2008 - 12:23 PM

lagos 1. Make some videos!

2. Get to the dyno. I a... Aug 27, 2008 - 12:23 PM

95st-celica great job guy's and girls....really clean work... Aug 27, 2008 - 12:45 PM

95st-celica great job guy's and girls....really clean work... Aug 27, 2008 - 12:45 PM

NuclearHappineS 2-3 lbs of boost from the cutout means that there ... Aug 27, 2008 - 12:51 PM

NuclearHappineS 2-3 lbs of boost from the cutout means that there ... Aug 27, 2008 - 12:51 PM

RUNNIN-LOW well humm...at 20psi my buddy got 304 to the wheel... Aug 27, 2008 - 12:51 PM

RUNNIN-LOW well humm...at 20psi my buddy got 304 to the wheel... Aug 27, 2008 - 12:51 PM

WALKER Nice work you guys. Looks great! Aug 27, 2008 - 1:16 PM

WALKER Nice work you guys. Looks great! Aug 27, 2008 - 1:16 PM

KAOS QUOTE (WALKER @ Aug 27, 2008 - 12:16... Aug 27, 2008 - 1:25 PM

KAOS QUOTE (WALKER @ Aug 27, 2008 - 12:16... Aug 27, 2008 - 1:25 PM

ETNRIDER Can my Ceilca come stay with you next weekend?? ..... Aug 27, 2008 - 1:53 PM

ETNRIDER Can my Ceilca come stay with you next weekend?? ..... Aug 27, 2008 - 1:53 PM

D-Man great work guys!! i cant believe you all k... Aug 27, 2008 - 2:25 PM

D-Man great work guys!! i cant believe you all k... Aug 27, 2008 - 2:25 PM

x_itchy_b_x being a 6gc OG (Original Gangsta) has it perks. Aug 27, 2008 - 2:33 PM

x_itchy_b_x being a 6gc OG (Original Gangsta) has it perks. Aug 27, 2008 - 2:33 PM

D-Man QUOTE (x_itchy_b_x @ Aug 27, 2008 - 2... Aug 27, 2008 - 2:49 PM

D-Man QUOTE (x_itchy_b_x @ Aug 27, 2008 - 2... Aug 27, 2008 - 2:49 PM

97lestyousay QUOTE (D-Man @ Aug 27, 2008 - 12... Aug 27, 2008 - 9:00 PM

97lestyousay QUOTE (D-Man @ Aug 27, 2008 - 12... Aug 27, 2008 - 9:00 PM

x_itchy_b_x why wasn't I informed sooner I like to play c... Aug 27, 2008 - 4:05 PM

x_itchy_b_x why wasn't I informed sooner I like to play c... Aug 27, 2008 - 4:05 PM

D-Man What are you doing with your old engine? it was a ... Aug 27, 2008 - 4:27 PM

D-Man What are you doing with your old engine? it was a ... Aug 27, 2008 - 4:27 PM

DEATH 5S-FE but yeah - you want his cams [I have a sneak... Aug 27, 2008 - 4:48 PM

DEATH 5S-FE but yeah - you want his cams [I have a sneak... Aug 27, 2008 - 4:48 PM

presure2 QUOTE (DEATH @ Aug 27, 2008 - 5:48 P... Aug 27, 2008 - 5:06 PM

presure2 QUOTE (DEATH @ Aug 27, 2008 - 5:48 P... Aug 27, 2008 - 5:06 PM

DEATH I KNEW you were gonna be the recipient of those ca... Aug 27, 2008 - 5:11 PM

DEATH I KNEW you were gonna be the recipient of those ca... Aug 27, 2008 - 5:11 PM

presure2 QUOTE (DEATH @ Aug 27, 2008 - 6:11 P... Aug 27, 2008 - 6:00 PM

presure2 QUOTE (DEATH @ Aug 27, 2008 - 6:11 P... Aug 27, 2008 - 6:00 PM

DEATH Nice - i assumed with the powerband being smoother... Aug 27, 2008 - 6:04 PM

DEATH Nice - i assumed with the powerband being smoother... Aug 27, 2008 - 6:04 PM

x_itchy_b_x i expect big gains with them Manny. more lift + du... Aug 27, 2008 - 6:20 PM

x_itchy_b_x i expect big gains with them Manny. more lift + du... Aug 27, 2008 - 6:20 PM

DEATH Exactly [itchy will you be my translator? That... Aug 27, 2008 - 6:21 PM

DEATH Exactly [itchy will you be my translator? That... Aug 27, 2008 - 6:21 PM

easternpiro1 whats the ps? and death i think ftmfbbqw means fo... Aug 27, 2008 - 6:22 PM

easternpiro1 whats the ps? and death i think ftmfbbqw means fo... Aug 27, 2008 - 6:22 PM

Batman722 QUOTE (easternpiro1 @ Aug 27, 2008 - 7... Aug 27, 2008 - 6:25 PM

Batman722 QUOTE (easternpiro1 @ Aug 27, 2008 - 7... Aug 27, 2008 - 6:25 PM

DEATH Or passenger side depending on the context.

MFBBQW... Aug 27, 2008 - 6:28 PM

DEATH Or passenger side depending on the context.

MFBBQW... Aug 27, 2008 - 6:28 PM

zero07 You guys did a great job in such a short time... Aug 27, 2008 - 6:59 PM

zero07 You guys did a great job in such a short time... Aug 27, 2008 - 6:59 PM

snapshotgt Dustin, here is the picture of my drivers side spa... Aug 27, 2008 - 11:05 PM

snapshotgt Dustin, here is the picture of my drivers side spa... Aug 27, 2008 - 11:05 PM

Batman722 thanks Snap lookin good ! Aug 27, 2008 - 11:09 PM

Batman722 thanks Snap lookin good ! Aug 27, 2008 - 11:09 PM

snapshotgt You car is officially an animal, congrats. Aug 28, 2008 - 12:43 AM

snapshotgt You car is officially an animal, congrats. Aug 28, 2008 - 12:43 AM

devilsden97 so this finally hit 6gc.net? lol

nice work.

soun... Aug 28, 2008 - 8:45 AM

devilsden97 so this finally hit 6gc.net? lol

nice work.

soun... Aug 28, 2008 - 8:45 AM

hurley97 QUOTE (devilsden97 @ Aug 28, 2008 - 9... Aug 28, 2008 - 8:19 PM

hurley97 QUOTE (devilsden97 @ Aug 28, 2008 - 9... Aug 28, 2008 - 8:19 PM

jcaron9gt4 so where is your 5's going?

i know someone th... Aug 28, 2008 - 9:42 AM

jcaron9gt4 so where is your 5's going?

i know someone th... Aug 28, 2008 - 9:42 AM

easternpiro1 QUOTE (Batman722 @ Aug 27, 2008 - 7... Aug 28, 2008 - 8:09 PM

easternpiro1 QUOTE (Batman722 @ Aug 27, 2008 - 7... Aug 28, 2008 - 8:09 PM

Havok1997GT Unreal job guys. Fantastic work. Aug 28, 2008 - 9:53 PM

Havok1997GT Unreal job guys. Fantastic work. Aug 28, 2008 - 9:53 PM

SeverX13 it look sooo clean. i love it.

props!

i... Aug 28, 2008 - 10:38 PM

SeverX13 it look sooo clean. i love it.

props!

i... Aug 28, 2008 - 10:38 PM

stetsonaw looks great! Aug 30, 2008 - 1:28 PM

stetsonaw looks great! Aug 30, 2008 - 1:28 PM

Batman722 and some info for others.

when I got the motor I n... Sep 8, 2008 - 4:53 PM

Batman722 and some info for others.

when I got the motor I n... Sep 8, 2008 - 4:53 PM

Batman722 oh yea, read this site a few times over.

http://w... Sep 8, 2008 - 5:03 PM

Batman722 oh yea, read this site a few times over.

http://w... Sep 8, 2008 - 5:03 PM

azian_advanced as i said before, good job to you and to the peopl... Sep 8, 2008 - 7:07 PM

azian_advanced as i said before, good job to you and to the peopl... Sep 8, 2008 - 7:07 PM

jeffrosie Hi batman722, very impressed with the work you hav... Sep 12, 2008 - 1:39 PM

jeffrosie Hi batman722, very impressed with the work you hav... Sep 12, 2008 - 1:39 PM

DEATH QUOTE (Batman722 @ Sep 18, 2008 - 9... Sep 19, 2008 - 9:44 AM

DEATH QUOTE (Batman722 @ Sep 18, 2008 - 9... Sep 19, 2008 - 9:44 AM

x_itchy_b_x QUOTE (Batman722 @ Sep 18, 2008 - 10... Sep 18, 2008 - 10:58 PM

x_itchy_b_x QUOTE (Batman722 @ Sep 18, 2008 - 10... Sep 18, 2008 - 10:58 PM

jeffrosie Thanks for the headsup on the axles batman, about ... Sep 19, 2008 - 7:44 PM

jeffrosie Thanks for the headsup on the axles batman, about ... Sep 19, 2008 - 7:44 PM

Batman722 QUOTE (jeffrosie @ Sep 19, 2008 - 8... Sep 22, 2008 - 11:16 AM

Batman722 QUOTE (jeffrosie @ Sep 19, 2008 - 8... Sep 22, 2008 - 11:16 AM

lagos damn you. I get a rocking 19mpg. Sep 22, 2008 - 1:52 PM

lagos damn you. I get a rocking 19mpg. Sep 22, 2008 - 1:52 PM

jgreening Looks great, Dustin. Congrats on the swap. I kne... Sep 22, 2008 - 1:56 PM

jgreening Looks great, Dustin. Congrats on the swap. I kne... Sep 22, 2008 - 1:56 PM

playr158 out of curiosity did you get an OBD2 motor? Sep 22, 2008 - 2:05 PM

playr158 out of curiosity did you get an OBD2 motor? Sep 22, 2008 - 2:05 PM

presure2 QUOTE (playr158 @ Sep 22, 2008 - 3:0... Sep 22, 2008 - 2:40 PM

presure2 QUOTE (playr158 @ Sep 22, 2008 - 3:0... Sep 22, 2008 - 2:40 PM

Batman722 2 quick vids

first is just a small pull 2nd to 3r... Sep 22, 2008 - 5:08 PM

Batman722 2 quick vids

first is just a small pull 2nd to 3r... Sep 22, 2008 - 5:08 PM

lagos cutout sounds nice dude. Sep 22, 2008 - 5:24 PM

lagos cutout sounds nice dude. Sep 22, 2008 - 5:24 PM

DEATH Sweet Sep 22, 2008 - 5:59 PM

DEATH Sweet Sep 22, 2008 - 5:59 PM

Batman722 those vids suck, I know. I will have better vids s... Sep 22, 2008 - 8:45 PM

Batman722 those vids suck, I know. I will have better vids s... Sep 22, 2008 - 8:45 PM

97lestyousay That cutout is the ****, the first one looks like ... Sep 24, 2008 - 12:56 AM

97lestyousay That cutout is the ****, the first one looks like ... Sep 24, 2008 - 12:56 AM

zero07 Sounds good............ but stop teasing us and po... Sep 24, 2008 - 8:31 AM

zero07 Sounds good............ but stop teasing us and po... Sep 24, 2008 - 8:31 AM

Daftboy yea it looks like the circle by pressure2's ho... Sep 24, 2008 - 8:55 AM

Daftboy yea it looks like the circle by pressure2's ho... Sep 24, 2008 - 8:55 AM

presure2 QUOTE (Daftboy @ Sep 24, 2008 - 9:55... Sep 24, 2008 - 9:17 AM

presure2 QUOTE (Daftboy @ Sep 24, 2008 - 9:55... Sep 24, 2008 - 9:17 AM

_mikeE I really like how you placed that wideband meter, ... Sep 25, 2008 - 1:03 AM

_mikeE I really like how you placed that wideband meter, ... Sep 25, 2008 - 1:03 AM

Batman722 the single pod was made by an overseas member here... Sep 25, 2008 - 7:10 AM

Batman722 the single pod was made by an overseas member here... Sep 25, 2008 - 7:10 AM

Daftboy When you taking this to the dyno....I want to see ... Sep 25, 2008 - 8:09 AM

Daftboy When you taking this to the dyno....I want to see ... Sep 25, 2008 - 8:09 AM

6strngs that's F'in sweet dude! congrats on th... Oct 16, 2008 - 1:32 AM

6strngs that's F'in sweet dude! congrats on th... Oct 16, 2008 - 1:32 AM

Batman722 just a quick update.

I installed some tworus bras... Oct 27, 2008 - 12:08 PM

Batman722 just a quick update.

I installed some tworus bras... Oct 27, 2008 - 12:08 PM

95celgt yea dustin, get rid of them, what i learned recent... Oct 28, 2008 - 4:38 PM

95celgt yea dustin, get rid of them, what i learned recent... Oct 28, 2008 - 4:38 PM

Batman722 went to the dyno today, I thought Jim was coming u... Feb 7, 2009 - 11:54 PM

Batman722 went to the dyno today, I thought Jim was coming u... Feb 7, 2009 - 11:54 PM

lagos it looks like youre running out of fuel. Feb 8, 2009 - 12:36 AM

lagos it looks like youre running out of fuel. Feb 8, 2009 - 12:36 AM

presure2 QUOTE (lagos @ Feb 8, 2009 - 12:36 A... Feb 8, 2009 - 8:01 AM

presure2 QUOTE (lagos @ Feb 8, 2009 - 12:36 A... Feb 8, 2009 - 8:01 AM

lagos I was going to say, that **** looked crazy lean...... Feb 8, 2009 - 10:53 AM

lagos I was going to say, that **** looked crazy lean...... Feb 8, 2009 - 10:53 AM

presure2 QUOTE (lagos @ Feb 8, 2009 - 10:53 A... Feb 8, 2009 - 10:55 AM

presure2 QUOTE (lagos @ Feb 8, 2009 - 10:53 A... Feb 8, 2009 - 10:55 AM

_Jim_ Great numbers Dustin, please send me the run files... Feb 8, 2009 - 11:01 AM

_Jim_ Great numbers Dustin, please send me the run files... Feb 8, 2009 - 11:01 AM

supershannon77 Awesome Dustin congrats Feb 8, 2009 - 11:56 AM

supershannon77 Awesome Dustin congrats Feb 8, 2009 - 11:56 AM

lagos Further proof that Dustin is THE MAN! Feb 8, 2009 - 12:05 PM

lagos Further proof that Dustin is THE MAN! Feb 8, 2009 - 12:05 PM

Defgeph Now thats what I call fried chicken. Thats bomb r... Feb 8, 2009 - 1:02 PM

Defgeph Now thats what I call fried chicken. Thats bomb r... Feb 8, 2009 - 1:02 PM

Batman722 thanks guys.

Yeah I was a little drunk last night... Feb 8, 2009 - 1:13 PM

Batman722 thanks guys.

Yeah I was a little drunk last night... Feb 8, 2009 - 1:13 PM

Batman722 hey Manny, post the pic of my car on the dyno ... Feb 8, 2009 - 1:16 PM

Batman722 hey Manny, post the pic of my car on the dyno ... Feb 8, 2009 - 1:16 PM

x_itchy_b_x AWESOME numbers. Feb 8, 2009 - 2:05 PM

x_itchy_b_x AWESOME numbers. Feb 8, 2009 - 2:05 PM

manphibian Big numbers! Nice work Feb 8, 2009 - 5:00 PM

manphibian Big numbers! Nice work Feb 8, 2009 - 5:00 PM

Fate wow that is awesome. is this what i have to look f... Feb 8, 2009 - 7:28 PM

Fate wow that is awesome. is this what i have to look f... Feb 8, 2009 - 7:28 PM

Supersprynt You guys are putting 6GCs on the map! Nice wor... Feb 8, 2009 - 10:52 PM

Supersprynt You guys are putting 6GCs on the map! Nice wor... Feb 8, 2009 - 10:52 PM

_Jim_ That is pretty consistent results, proving what t... Feb 8, 2009 - 11:00 PM

_Jim_ That is pretty consistent results, proving what t... Feb 8, 2009 - 11:00 PM

playr158 WOOOHOOOO Dustin!

thanks for the call letting... Feb 9, 2009 - 7:22 AM

playr158 WOOOHOOOO Dustin!

thanks for the call letting... Feb 9, 2009 - 7:22 AM  |

4 User(s) are reading this topic (4 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 26th, 2024 - 6:10 PM |