Jan 6, 2007 - 4:04 PM Jan 6, 2007 - 4:04 PM

|

|

Enthusiast      Joined Feb 3, '06 From Czech Republic (Europe) Currently Offline Reputation: 56 (100%) |

At last I had some time for another upgrade. Steering wheel swap... My stock one was 4-spoke with airbag/horn in the middle.

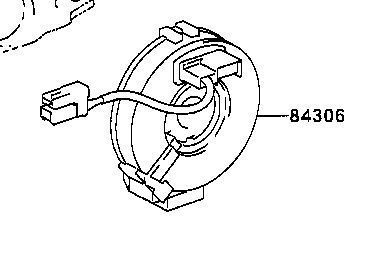

Just history now  Although horn mechanism and airbag connector were different everything is working now. And I'll try describe here how generally do that... believe it will be handy for anyone step no one: remove old steering wheel Two screws on sides (behind small covers) holds airbag part   There are just two plugs inside. That yellow one is for airbag and white is horn (there is possibility also for cruise multi switch, where are many more wires. Horn wire is black, every time that last on right connected to wheel body)  When you unplug everything + unscrew nut in the middle you should remove wheel with puller (w/o that it's not possible at all)  step two: solving airbag connection  Different airbag connector means find right module (spiral) for it...  ...or use same airbag refill   Of course... some customization should be done if airbag refill has different size (more are different, more custom work is needed). My one was just bit different... and airbag part was easy take into parts.  step three: solving horn connection This step depends on type of horn you have. However every time it's about find how horn mechanism works, cut black wire off old wheel and connect it somewhere... It really depends on that horn mechanism. However it's really easy, just one wire to screw... somewhere step four: piece everything together Installation of new wheel body (with same center bore of course) is easy...  ...and in my case screw horn cable to airbag body (not wheel body like stock one)...and all finished

This post has been edited by malpaso: Jan 6, 2007 - 4:27 PM -------------------- No more replicas... This is evolution... This is SS-four :)

________[Featured Celica of 6gc.net @ 2010]_________ |

|

Replies

Jun 17, 2009 - 8:46 PM Jun 17, 2009 - 8:46 PM

|

|

|

Enthusiast    Joined Jul 2, '08 From SoCal Currently Offline Reputation: 6 (100%) |

ok, i finished wiring the horn in last weekend, so i'll post up what i did in case any of you guys do an aftermarket wheel like me. i used an NRG steering wheel with an NRG quick release and a SPARCO steering wheel hub. for connectors, i used 2 eyelet connectors and an inline splice connector. the reason i used the inline splice connector was in case i want to put the stock wheel back in, i didn't FUBAR the wiring or stock connector. plus its easy to put in and take off if needed.

there were two wires on the quick release and steering wheel horn button, but there was only one wire on the hub. basically i ended up using the one wire from the hub as the positive (signal wire) for the horn, and then i used one of the eyelet connectors on the black wire from the quick release as the ground. i grounded it via one of the screws that attaches the quick release to the hub. there is a metal shim that goes between the quick release and the hub, so you will need to take some cutters and trim out a notch big enough for the connector.   after you get the quick release or wheel firmly attached to the hub, you'll want to move onto locating the signal wire for the horn at the connecter by the steering column. its the green wire at the end of the connector. an easy way to make sure is to take a short piece of wire, slide one end in the connector which is the contact for the green wire and ground it out. if you have the right wire, the horn will beep. i highly recommend doing this with the key out of the ignition. it will work without the key, and the reason i recommend doing it with the key off is so you don't short to ground a different circuit and fry it.  now you're going to need to make a wire that will go from the green wire to the back of the hub. there is a contact area that you need to touch the signal wire to. the contact is the gold colored ring that allows you to keep contact while the wheel is turning. in order to keep the signal wire contacting the gold ring on the back of the hub, i made a bracket that will constantly touch the gold ring. i made it from a piece of scrap metal i had laying around. it is important to make a smooth curve to the side that will contact the ring, as you don't want to scrape the hell out of the ring, which will lead to wear and a scraping noise.   the part in between my fingers is the part that touches the gold ring. now you'll want to cut some 16 gauge wire (keep very close to the same size wire as what is at the connector from the steering column) to about 5". on one end you will want to put the second eyelet connector. the end with nothing on it is where you will use the inline splice connector at the green wire.  as for a place to put the bracket i made to contact the gold ring, i am just using the attaching point where the stock clock spring (steering angle sensor) screwed in, and i used the screw from the clock spring as well. sandwich the eyelet connector from the wire and the bracket, then tighten down the screw.  make sure that the curve is directed to make the smoothest path on the gold ring and make sure there is decent tension on the bracket.  don't forget to double check your work through the process and keep checking to see if the horn works through the process. if you keep checking as you go, then the less you have to back track if you make a mistake. it's pretty simple and easy though. |

Posts in this topic

malpaso Steering wheel swap guide Jan 6, 2007 - 4:04 PM

malpaso Steering wheel swap guide Jan 6, 2007 - 4:04 PM

snapshotgt Very nice Jan 6, 2007 - 4:16 PM

snapshotgt Very nice Jan 6, 2007 - 4:16 PM

zCelicaDude very nice guide. this will be very helpful to the ... Jan 6, 2007 - 4:18 PM

zCelicaDude very nice guide. this will be very helpful to the ... Jan 6, 2007 - 4:18 PM

My2Celi nice i like it a lot. How much did you get the ste... Jan 6, 2007 - 7:46 PM

My2Celi nice i like it a lot. How much did you get the ste... Jan 6, 2007 - 7:46 PM

Batman722 Nice Job Martin Jan 7, 2007 - 12:35 AM

Batman722 Nice Job Martin Jan 7, 2007 - 12:35 AM

malpaso thanks for posts and PMs. Here is additional info:... Jan 7, 2007 - 2:39 AM

malpaso thanks for posts and PMs. Here is additional info:... Jan 7, 2007 - 2:39 AM

tomazws Nice swap dude! That 7th gen steering wheel l... Jan 7, 2007 - 4:55 PM

tomazws Nice swap dude! That 7th gen steering wheel l... Jan 7, 2007 - 4:55 PM

My2Celi aww. i guess i wont be doing it. US import cars ar... Jan 7, 2007 - 10:53 PM

My2Celi aww. i guess i wont be doing it. US import cars ar... Jan 7, 2007 - 10:53 PM

Rockford Excellent work, congrats!!!! Jan 7, 2007 - 11:19 PM

Rockford Excellent work, congrats!!!! Jan 7, 2007 - 11:19 PM

CelicaSweden Which size is the puller?

100mm, 150mm or 200 mm ?... Feb 10, 2007 - 9:19 AM

CelicaSweden Which size is the puller?

100mm, 150mm or 200 mm ?... Feb 10, 2007 - 9:19 AM

malpaso QUOTE(CelicaSweden @ Feb 10, 2007 - 3... Feb 10, 2007 - 10:43 AM

malpaso QUOTE(CelicaSweden @ Feb 10, 2007 - 3... Feb 10, 2007 - 10:43 AM

CelicaSweden QUOTE(malpaso @ Feb 10, 2007 - 10:43... Feb 11, 2007 - 3:16 AM

CelicaSweden QUOTE(malpaso @ Feb 10, 2007 - 10:43... Feb 11, 2007 - 3:16 AM

malpaso QUOTE(CelicaSweden @ Feb 11, 2007 - 9... Feb 11, 2007 - 3:28 AM

malpaso QUOTE(CelicaSweden @ Feb 11, 2007 - 9... Feb 11, 2007 - 3:28 AM

Excursion745 7th gen/MR2/MR-S st. wheel. Where and how much?: I... Feb 11, 2007 - 11:18 PM

Excursion745 7th gen/MR2/MR-S st. wheel. Where and how much?: I... Feb 11, 2007 - 11:18 PM

malpaso QUOTE(Excursion745 @ Feb 12, 2007 - 5... Feb 12, 2007 - 2:29 AM

malpaso QUOTE(Excursion745 @ Feb 12, 2007 - 5... Feb 12, 2007 - 2:29 AM

Batman722 I was lucky enough to get my hands on some 7th gen... Feb 27, 2007 - 10:56 PM

Batman722 I was lucky enough to get my hands on some 7th gen... Feb 27, 2007 - 10:56 PM

malpaso QUOTE(Batman722 @ Feb 28, 2007 - 4:5... Feb 28, 2007 - 1:43 AM

malpaso QUOTE(Batman722 @ Feb 28, 2007 - 4:5... Feb 28, 2007 - 1:43 AM

dutchboy QUOTE(Batman722 @ Feb 27, 2007 - 10... Jul 11, 2007 - 3:13 PM

dutchboy QUOTE(Batman722 @ Feb 27, 2007 - 10... Jul 11, 2007 - 3:13 PM

j0e_p3t nice. now i'm really thinking about doing this... Feb 27, 2007 - 11:13 PM

j0e_p3t nice. now i'm really thinking about doing this... Feb 27, 2007 - 11:13 PM

Batman722 the 7th gen clockspring (spiral) does not fit in t... Feb 28, 2007 - 8:52 AM

Batman722 the 7th gen clockspring (spiral) does not fit in t... Feb 28, 2007 - 8:52 AM

malpaso QUOTE(Batman722 @ Feb 28, 2007 - 2:5... Feb 28, 2007 - 9:30 AM

malpaso QUOTE(Batman722 @ Feb 28, 2007 - 2:5... Feb 28, 2007 - 9:30 AM

Batman722 Martin NO !!! I cut here not the bag ... Feb 28, 2007 - 11:20 AM

Batman722 Martin NO !!! I cut here not the bag ... Feb 28, 2007 - 11:20 AM

malpaso cunning Feb 28, 2007 - 12:09 PM

malpaso cunning Feb 28, 2007 - 12:09 PM

Negative There is also a 6th gen steering wheel that looks ... Feb 28, 2007 - 2:27 PM

Negative There is also a 6th gen steering wheel that looks ... Feb 28, 2007 - 2:27 PM

tankd0g QUOTE(Negative @ Feb 28, 2007 - 2:27... Apr 1, 2008 - 8:42 PM

tankd0g QUOTE(Negative @ Feb 28, 2007 - 2:27... Apr 1, 2008 - 8:42 PM

Batman722 correct. The 98-99s had a 3 spoke also. IMO the 7t... Feb 28, 2007 - 2:41 PM

Batman722 correct. The 98-99s had a 3 spoke also. IMO the 7t... Feb 28, 2007 - 2:41 PM

Batman722 and some more pics

I still need to clean an... Feb 28, 2007 - 6:07 PM

Batman722 and some more pics

I still need to clean an... Feb 28, 2007 - 6:07 PM

azian_advanced are all 7th gen steering wheels the same? do any ... Mar 1, 2007 - 2:25 AM

azian_advanced are all 7th gen steering wheels the same? do any ... Mar 1, 2007 - 2:25 AM

malpaso QUOTE(azian_advanced @ Mar 1, 2007 - 8... Mar 1, 2007 - 2:43 AM

malpaso QUOTE(azian_advanced @ Mar 1, 2007 - 8... Mar 1, 2007 - 2:43 AM

Batman722 QUOTE(azian_advanced @ Mar 1, 2007 - 2... Mar 1, 2007 - 11:05 AM

Batman722 QUOTE(azian_advanced @ Mar 1, 2007 - 2... Mar 1, 2007 - 11:05 AM

Negative So is my stock 3 post. Well pleather or whatever T... Mar 1, 2007 - 9:46 AM

Negative So is my stock 3 post. Well pleather or whatever T... Mar 1, 2007 - 9:46 AM

kerosene even though o wasn't replacing my steering whe... Jul 8, 2007 - 4:17 PM

kerosene even though o wasn't replacing my steering whe... Jul 8, 2007 - 4:17 PM

Kadett I really want one. To bad there aren't any ava... Jul 9, 2007 - 7:00 AM

Kadett I really want one. To bad there aren't any ava... Jul 9, 2007 - 7:00 AM

Kadett Found Myself a nice Leather 7th gen steering wheel... Jul 23, 2007 - 10:17 AM

Kadett Found Myself a nice Leather 7th gen steering wheel... Jul 23, 2007 - 10:17 AM

dutchboy Anyone know if the 6th gen cruise control switch w... Jul 25, 2007 - 4:48 AM

dutchboy Anyone know if the 6th gen cruise control switch w... Jul 25, 2007 - 4:48 AM

malpaso QUOTE(dutchboy @ Jul 25, 2007 - 11:4... Jul 25, 2007 - 4:57 AM

malpaso QUOTE(dutchboy @ Jul 25, 2007 - 11:4... Jul 25, 2007 - 4:57 AM

dutchboy Is the back side of the 7th gen wheel metal or pla... Jul 25, 2007 - 8:19 PM

dutchboy Is the back side of the 7th gen wheel metal or pla... Jul 25, 2007 - 8:19 PM

njccmd2002 Now all you have to do is test the airbag to see i... Jul 25, 2007 - 8:26 PM

njccmd2002 Now all you have to do is test the airbag to see i... Jul 25, 2007 - 8:26 PM

thespacepanda Nice write-up, man.

Just out of curiosity, if I w... Jan 22, 2008 - 10:23 PM

thespacepanda Nice write-up, man.

Just out of curiosity, if I w... Jan 22, 2008 - 10:23 PM

reko Taking the thread back from the dead lolů.

Quick ... Apr 2, 2009 - 1:04 PM

reko Taking the thread back from the dead lolů.

Quick ... Apr 2, 2009 - 1:04 PM

njccmd2002 take the momo steering of, and show us a picture. ... Apr 2, 2009 - 6:34 PM

njccmd2002 take the momo steering of, and show us a picture. ... Apr 2, 2009 - 6:34 PM

windowlicker quick question, is there any special process when ... Apr 7, 2009 - 6:25 PM

windowlicker quick question, is there any special process when ... Apr 7, 2009 - 6:25 PM

njccmd2002 do the safest, disconnect the battery. Apr 7, 2009 - 6:43 PM

njccmd2002 do the safest, disconnect the battery. Apr 7, 2009 - 6:43 PM

windowlicker will do. i get spoiled with the mercedes airbags ... Apr 7, 2009 - 6:48 PM

windowlicker will do. i get spoiled with the mercedes airbags ... Apr 7, 2009 - 6:48 PM

deliriouzgtfour any other precautions before starting...? like dis... Apr 14, 2009 - 12:41 AM

deliriouzgtfour any other precautions before starting...? like dis... Apr 14, 2009 - 12:41 AM

malpaso QUOTE (deliriouzgtfour @ Apr 14, 2009 - ... Apr 14, 2009 - 2:13 AM

malpaso QUOTE (deliriouzgtfour @ Apr 14, 2009 - ... Apr 14, 2009 - 2:13 AM

deliriouzgtfour fixed my horn. On the other hand, wire was torn i... Apr 14, 2009 - 4:17 PM

deliriouzgtfour fixed my horn. On the other hand, wire was torn i... Apr 14, 2009 - 4:17 PM

windowlicker took the airbag off this morning to speed up the p... Apr 22, 2009 - 1:18 PM

windowlicker took the airbag off this morning to speed up the p... Apr 22, 2009 - 1:18 PM

azian_advanced as long as the 7th gen wheel you get comes with th... Apr 22, 2009 - 1:56 PM

azian_advanced as long as the 7th gen wheel you get comes with th... Apr 22, 2009 - 1:56 PM

windowlicker oh, i'm not putting in a toyota wheel, i'm... Apr 22, 2009 - 2:12 PM

windowlicker oh, i'm not putting in a toyota wheel, i'm... Apr 22, 2009 - 2:12 PM

reko Hey I'm having a hard time trying to put the s... Apr 22, 2009 - 9:56 PM

reko Hey I'm having a hard time trying to put the s... Apr 22, 2009 - 9:56 PM

windowlicker well its a little late for this now, but what i ha... Apr 22, 2009 - 11:17 PM

windowlicker well its a little late for this now, but what i ha... Apr 22, 2009 - 11:17 PM

azian_advanced yeah the wheel is supposed to be very tight.. use ... Apr 22, 2009 - 11:25 PM

azian_advanced yeah the wheel is supposed to be very tight.. use ... Apr 22, 2009 - 11:25 PM

windowlicker QUOTE (azian_advanced @ Apr 23, 2009 - 1... Apr 22, 2009 - 11:50 PM

windowlicker QUOTE (azian_advanced @ Apr 23, 2009 - 1... Apr 22, 2009 - 11:50 PM

reko That's the thing... i have a garage, impact gu... Apr 23, 2009 - 8:25 AM

reko That's the thing... i have a garage, impact gu... Apr 23, 2009 - 8:25 AM

chacha what's the part number for the clock spring...... May 1, 2009 - 10:21 AM

chacha what's the part number for the clock spring...... May 1, 2009 - 10:21 AM

Superaison I did this today.

Was really easy, I didnt **** ... Jun 4, 2009 - 7:55 PM

Superaison I did this today.

Was really easy, I didnt **** ... Jun 4, 2009 - 7:55 PM

Dragondog i got a question if you swap wheels with one thats... Jun 5, 2009 - 1:57 AM

Dragondog i got a question if you swap wheels with one thats... Jun 5, 2009 - 1:57 AM

windowlicker QUOTE (Dragondog @ Jun 5, 2009 - 2:5... Jun 7, 2009 - 9:12 PM

windowlicker QUOTE (Dragondog @ Jun 5, 2009 - 2:5... Jun 7, 2009 - 9:12 PM

windowlicker here's some pics of the nrg wheel, nrg quick r... Jun 7, 2009 - 9:09 PM

windowlicker here's some pics of the nrg wheel, nrg quick r... Jun 7, 2009 - 9:09 PM

AnaXyd Will this swap from f.ex the Celica T23 to T20 act... Jun 20, 2009 - 10:27 AM

AnaXyd Will this swap from f.ex the Celica T23 to T20 act... Jun 20, 2009 - 10:27 AM

AnaXyd QUOTE (AnaXyd @ Jun 20, 2009 - 10:27... Aug 7, 2009 - 9:51 AM

AnaXyd QUOTE (AnaXyd @ Jun 20, 2009 - 10:27... Aug 7, 2009 - 9:51 AM

tankd0g I just swapped a 99 rav4 wheel into my 5th gen (lo... Jul 23, 2009 - 12:25 AM

tankd0g I just swapped a 99 rav4 wheel into my 5th gen (lo... Jul 23, 2009 - 12:25 AM

shegarhuney GUYS!!.. i want to share a very very impor... Jul 28, 2009 - 4:29 PM

shegarhuney GUYS!!.. i want to share a very very impor... Jul 28, 2009 - 4:29 PM

zonz540 I swapped a GT4 wheel w/out an airbag into my 6gc ... Jul 29, 2009 - 1:06 AM

zonz540 I swapped a GT4 wheel w/out an airbag into my 6gc ... Jul 29, 2009 - 1:06 AM

GriffGirl this should be stickied! Jan 10, 2010 - 7:16 PM

GriffGirl this should be stickied! Jan 10, 2010 - 7:16 PM

Wintersun Have a Gen 7 wheel in my Gen 6 SSIII and was easy ... Jan 10, 2010 - 8:58 PM

Wintersun Have a Gen 7 wheel in my Gen 6 SSIII and was easy ... Jan 10, 2010 - 8:58 PM

abraxxa Thanks to malpaso who redirected me to this thread... Jan 16, 2010 - 3:52 AM

abraxxa Thanks to malpaso who redirected me to this thread... Jan 16, 2010 - 3:52 AM

malpaso QUOTE (abraxxa @ Jan 16, 2010 - 9:52... Jan 16, 2010 - 11:14 AM

malpaso QUOTE (abraxxa @ Jan 16, 2010 - 9:52... Jan 16, 2010 - 11:14 AM

GriffGirl QUOTE (malpaso @ Jan 16, 2010 - 8:14... Jan 16, 2010 - 3:00 PM

GriffGirl QUOTE (malpaso @ Jan 16, 2010 - 8:14... Jan 16, 2010 - 3:00 PM

devilsden97 Does the RHD JDM st205 wheel have an air bag? and ... Jan 16, 2010 - 12:25 PM

devilsden97 Does the RHD JDM st205 wheel have an air bag? and ... Jan 16, 2010 - 12:25 PM

shegarhuney no more fuss.. the missing link ladies n gentlemen... Jan 18, 2010 - 5:34 PM

shegarhuney no more fuss.. the missing link ladies n gentlemen... Jan 18, 2010 - 5:34 PM

GriffGirl QUOTE (shegarhuney @ Jan 18, 2010 - 2... Feb 16, 2010 - 3:50 PM

GriffGirl QUOTE (shegarhuney @ Jan 18, 2010 - 2... Feb 16, 2010 - 3:50 PM

GriffGirl Since this thread is pretty much the most thorough... Jan 20, 2010 - 5:25 PM

GriffGirl Since this thread is pretty much the most thorough... Jan 20, 2010 - 5:25 PM

GriffGirl QUOTE (GriffGirl @ Jan 20, 2010 - 2... Feb 16, 2010 - 4:52 PM

GriffGirl QUOTE (GriffGirl @ Jan 20, 2010 - 2... Feb 16, 2010 - 4:52 PM

malpaso OMG... I really didn't know what my now 3 year... Jan 21, 2010 - 8:32 AM

malpaso OMG... I really didn't know what my now 3 year... Jan 21, 2010 - 8:32 AM

GriffGirl Now, back to that cruise stalk swap! I'm c... Jan 22, 2010 - 12:03 AM

GriffGirl Now, back to that cruise stalk swap! I'm c... Jan 22, 2010 - 12:03 AM

Batman722 I just looked over my notes, it's not super cl... Jan 22, 2010 - 8:23 AM

Batman722 I just looked over my notes, it's not super cl... Jan 22, 2010 - 8:23 AM

GriffGirl QUOTE (Batman722 @ Jan 22, 2010 - 5... Feb 16, 2010 - 4:01 PM

GriffGirl QUOTE (Batman722 @ Jan 22, 2010 - 5... Feb 16, 2010 - 4:01 PM

samir0189 QUOTE (GriffGirl @ Feb 16, 2010 - 5... Feb 16, 2010 - 4:15 PM

samir0189 QUOTE (GriffGirl @ Feb 16, 2010 - 5... Feb 16, 2010 - 4:15 PM

shegarhuney hehe.. Jan 29, 2010 - 4:38 PM

shegarhuney hehe.. Jan 29, 2010 - 4:38 PM

abraxxa Good to see that the adapter fits!

I'm sti... Jan 29, 2010 - 5:16 PM

abraxxa Good to see that the adapter fits!

I'm sti... Jan 29, 2010 - 5:16 PM

yarik83 malpaso. I understand that you need a puller to re... Jan 29, 2010 - 5:42 PM

yarik83 malpaso. I understand that you need a puller to re... Jan 29, 2010 - 5:42 PM

abraxxa I removed mine about a year ago without a puller b... Jan 29, 2010 - 5:49 PM

abraxxa I removed mine about a year ago without a puller b... Jan 29, 2010 - 5:49 PM

malpaso QUOTE (abraxxa @ Jan 29, 2010 - 11:4... Jan 30, 2010 - 1:56 AM

malpaso QUOTE (abraxxa @ Jan 29, 2010 - 11:4... Jan 30, 2010 - 1:56 AM

GriffGirl I needed a puller to remove my 4 spoke wheel, defi... Jan 30, 2010 - 1:21 AM

GriffGirl I needed a puller to remove my 4 spoke wheel, defi... Jan 30, 2010 - 1:21 AM

samir0189 ive got the BGB, thats why i was asking if thats h... Feb 16, 2010 - 4:55 PM

samir0189 ive got the BGB, thats why i was asking if thats h... Feb 16, 2010 - 4:55 PM

GriffGirl I think you're right, I think it's somethi... Feb 16, 2010 - 5:09 PM

GriffGirl I think you're right, I think it's somethi... Feb 16, 2010 - 5:09 PM

Arsaces Hey guys,

I am thinking hard about doing this swa... Sep 15, 2011 - 10:02 AM

Arsaces Hey guys,

I am thinking hard about doing this swa... Sep 15, 2011 - 10:02 AM

abraxxa Just buy the adapter posted above. Sep 15, 2011 - 11:22 AM

abraxxa Just buy the adapter posted above. Sep 15, 2011 - 11:22 AM

Arsaces QUOTE (abraxxa @ Sep 15, 2011 - 11:2... Sep 15, 2011 - 12:39 PM

Arsaces QUOTE (abraxxa @ Sep 15, 2011 - 11:2... Sep 15, 2011 - 12:39 PM

spy00005 buy the adapter and just leave the cruise control ... Sep 15, 2011 - 12:46 PM

spy00005 buy the adapter and just leave the cruise control ... Sep 15, 2011 - 12:46 PM

Arsaces QUOTE (spy00005 @ Sep 15, 2011 - 1:4... Sep 15, 2011 - 12:51 PM

Arsaces QUOTE (spy00005 @ Sep 15, 2011 - 1:4... Sep 15, 2011 - 12:51 PM

trdproven i disabled my cruise control, the red stitch steer... Sep 22, 2011 - 10:05 PM

trdproven i disabled my cruise control, the red stitch steer... Sep 22, 2011 - 10:05 PM

Arsaces Hey guys, got my steering wheel on, I would like t... Sep 23, 2011 - 8:30 PM

Arsaces Hey guys, got my steering wheel on, I would like t... Sep 23, 2011 - 8:30 PM

spy00005 i used the old cc in my old steering wheel had but... Sep 23, 2011 - 8:51 PM

spy00005 i used the old cc in my old steering wheel had but... Sep 23, 2011 - 8:51 PM

Arsaces QUOTE (spy00005 @ Sep 23, 2011 - 9:5... Sep 23, 2011 - 9:41 PM

Arsaces QUOTE (spy00005 @ Sep 23, 2011 - 9:5... Sep 23, 2011 - 9:41 PM

spy00005 which steering wheel are you using because the old... Sep 24, 2011 - 12:58 AM

spy00005 which steering wheel are you using because the old... Sep 24, 2011 - 12:58 AM

Arsaces QUOTE (spy00005 @ Sep 24, 2011 - 1:5... Sep 24, 2011 - 4:06 PM

Arsaces QUOTE (spy00005 @ Sep 24, 2011 - 1:5... Sep 24, 2011 - 4:06 PM  |

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 5th, 2024 - 1:25 AM |