Sep 18, 2009 - 12:02 PM Sep 18, 2009 - 12:02 PM

|

|

|

Enthusiast   Joined Jan 28, '09 From Austin, TX Currently Offline Reputation: 0 (0%) |

EDIT START 9/22/2009

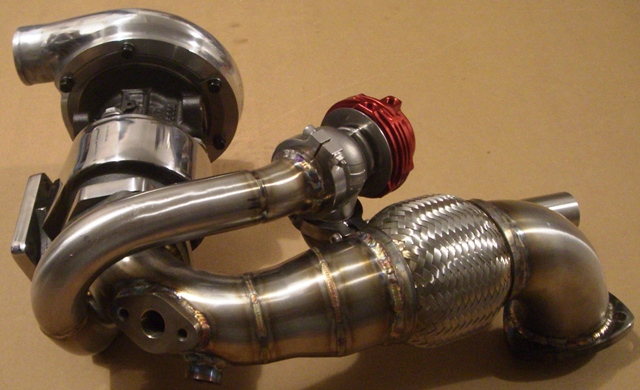

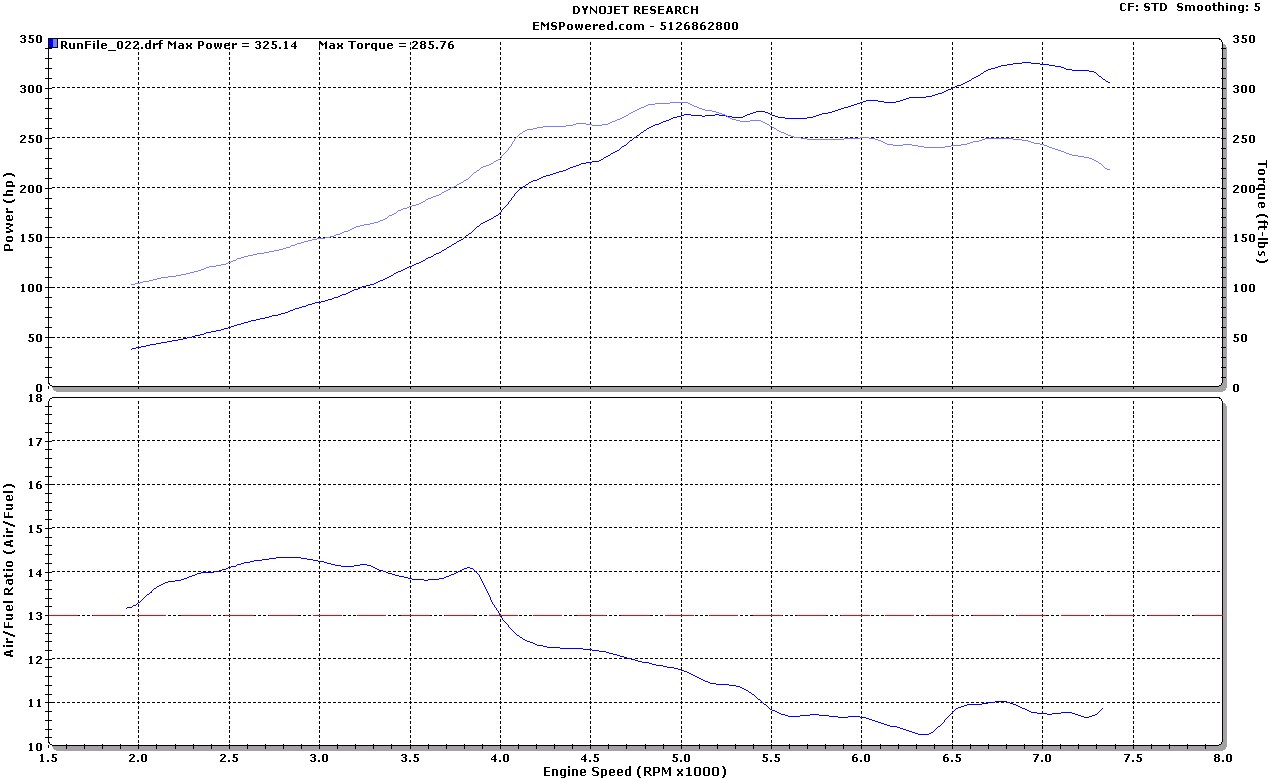

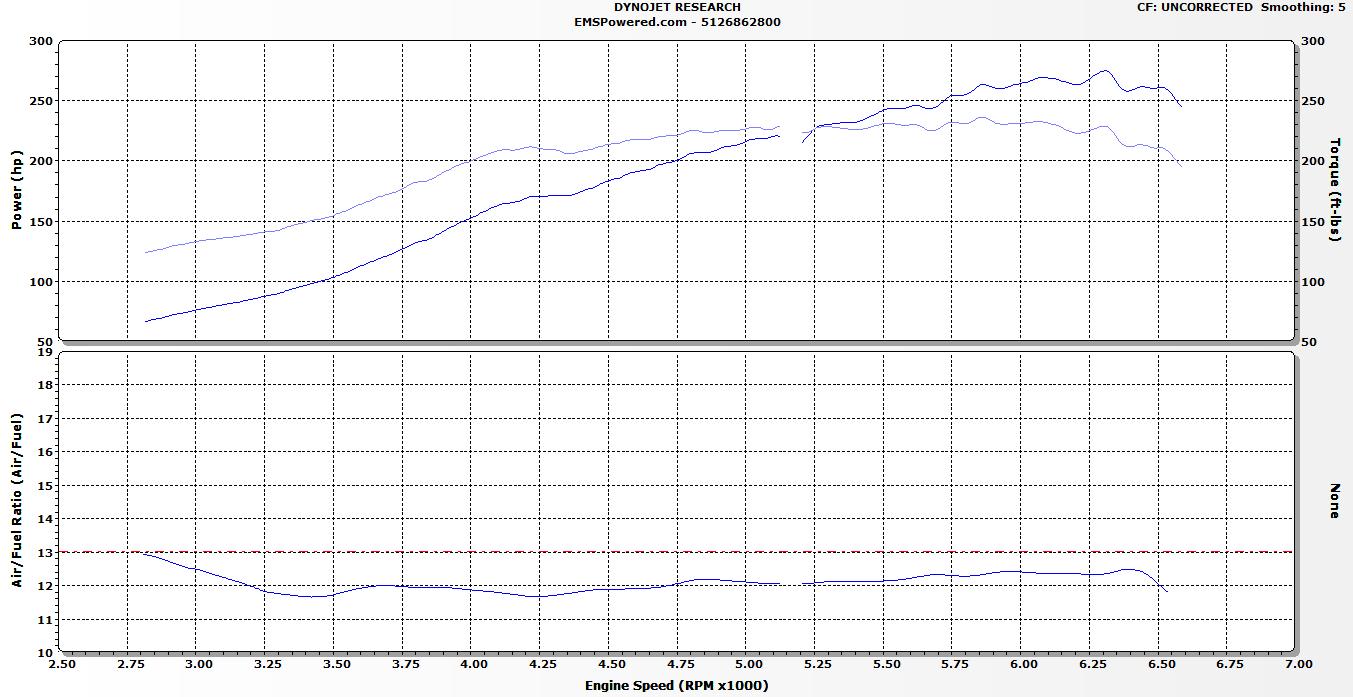

Pictures of the final version of the downpipe * v-band 38mm TIAL wastegate * All stainless steel * Stainless steel 3" interlocking flex section * Included wideband O2 sensor bung and Toyota O2 sensor bung   EDIT END 9/22/2009 We're finishing up the final revisions to our turbo kit. The final production version should be available for sale soon (within the next few months). Revisions from what you've seen in the past from various prototypes: * Flex section added to the downpipe * Tial 38mm v-band external wastegate option * Stainless steel turbine housing * -4AN braided stainless steel oil feed * -10AN braided stainless steel oil drain * Stainless steel 3" downpipe * Stock heatshield works and bolts on with our kit * Turbine inlet gasket matched for maximum flow * Various configurations available to support anywhere from an insanely fast spooling 300whp setup all the way to a monster 600whp capable setup that will spool quicker than any other 600whp capaable turbo kit around. * Lifetime warranty on the tubo kit (1 year on the turbo internals) * Kit made in the USA * The turbo's being used with the kit are manufactured by Borg Warner A few more pictures    A couple dyno's from various setups that some of our testers have been playing around with: Stock Gen3 3sgte MR2. 93 octane pump gas. Stock Longblock. Stock ECU. Stock fueling. No tuning. EMSPowered 4" intake. EMSPowered S252 Turbo Kit @ 17psi (this turbo is capable of around 450-500whp:  Gen2 3sgte MR2. 93 octane pump gas. Stock cams. 550cc injectors. EMSPowered 50trim Turbo Kit @ 14psi (this turbo is capable of around 400-450whp). This was a prototype kit that was not using our new Stainless Steel turbine housing, so spool is slower by about 150rpm on this dyno and power is lower by about 15-30hp:

This post has been edited by baktasht: Sep 25, 2009 - 1:10 PM -------------------- |

|

Replies

Sep 18, 2009 - 6:49 PM Sep 18, 2009 - 6:49 PM

|

|

|

Enthusiast  Joined Sep 14, '09 Currently Offline Reputation: 1 (100%) |

I truly hate to post seemingly negative comments about admirable endeavors such as this kind, but I can't seem to keep my mouth shut about my personal grievances. So please take what I'm about to say as positively as possible. I really mean no harm by it.

This is ONLY my opinion. As a company or businessman with aspirations of developing a Turbo Kit (or anything) that will increase the performance of an engine that has already been flagged as one having a very high level of performance potential in stock trim, the engineering approach should follow stringent quality control measures to ensure that the end product is both marketable, and a viable purchase for the end user. Considering this, my approach in developing such a kit would be to carefully detail the parameters of testing to be used for the development and fine tuning of the kit to be manufactured. Then, BEFORE beginning to manufacture said upgrade kit, have a fully refurbished/rebuilt BONE STOCK unit operating within the best performance specifications as outlined by the manufacturer. you know static compression, engine clearances, new distributor cap and rotor/spark cables etc etc. This engine should then be put through the full spectrum of tuning and tweaking to observe and document the limitations of the engine's full potential in completely stock configuration from a PERFORMANCE ONLY standpoint. Again just to emphasize, these tests MUST based on the same tuning and testing the engine being used for the turbo kit's development, is expected to go through. Then you can have all the data and dyno sheets from both the OEM spec as well as the upgrade spec setup, to display to perspective buyers of your upgrade kit. This type of approach clearly demonstrates the strong points and weaknesses of the upgrade product and puts both the buyer as well as the manufacturer in the driver's seat in terms of the "no surprises" aspect. This is what makes you a reputable after market performance equipment manufacturer. Just for argument's sake suppose that after the final release of your kit, another private tuner can provide a dyno sheet, clearly displaying that for approximately half the cost of turbo kit she/he was able to fit "drop in", replacement upgrade camshafts to the stock gen3 motor, and a piggyback tuning device, and achieve exactly the same peak dyno figures results with considerably better low RPM torque/response and significantly less installation headache? |

Posts in this topic

baktasht EMSPowered Turbo Kit - Coming Soon! Sep 18, 2009 - 12:02 PM

baktasht EMSPowered Turbo Kit - Coming Soon! Sep 18, 2009 - 12:02 PM

Mstoochn would of been nice to of seen this like... 3 weeks... Sep 18, 2009 - 1:53 PM

Mstoochn would of been nice to of seen this like... 3 weeks... Sep 18, 2009 - 1:53 PM

baktasht QUOTE (Mstoochn @ Sep 18, 2009 - 1:5... Sep 18, 2009 - 2:02 PM

baktasht QUOTE (Mstoochn @ Sep 18, 2009 - 1:5... Sep 18, 2009 - 2:02 PM

95st-celica maybe im missing something here...but on a stock 3... Sep 18, 2009 - 2:39 PM

95st-celica maybe im missing something here...but on a stock 3... Sep 18, 2009 - 2:39 PM

_Jim_ QUOTE (95st-celica @ Sep 18, 2009 ... Sep 18, 2009 - 2:48 PM

_Jim_ QUOTE (95st-celica @ Sep 18, 2009 ... Sep 18, 2009 - 2:48 PM

baktasht QUOTE (95st-celica @ Sep 18, 2009 ... Sep 18, 2009 - 3:17 PM

baktasht QUOTE (95st-celica @ Sep 18, 2009 ... Sep 18, 2009 - 3:17 PM

_Jim_ GREAT STUFF BAKTASH, I got my turbo in last week a... Sep 18, 2009 - 2:40 PM

_Jim_ GREAT STUFF BAKTASH, I got my turbo in last week a... Sep 18, 2009 - 2:40 PM

95st-celica i didnt know all the little detalis...that makes s... Sep 18, 2009 - 3:26 PM

95st-celica i didnt know all the little detalis...that makes s... Sep 18, 2009 - 3:26 PM

_Jim_ QUOTE (6gtfour @ Sep 18, 2009 - 7:49... Sep 18, 2009 - 7:17 PM

_Jim_ QUOTE (6gtfour @ Sep 18, 2009 - 7:49... Sep 18, 2009 - 7:17 PM

6gtfour QUOTE (_Jim_ @ Sep 18, 2009 - 7:17 P... Sep 18, 2009 - 8:15 PM

6gtfour QUOTE (_Jim_ @ Sep 18, 2009 - 7:17 P... Sep 18, 2009 - 8:15 PM

_Jim_ QUOTE (6gtfour @ Sep 18, 2009 - 9:15... Sep 19, 2009 - 7:50 AM

_Jim_ QUOTE (6gtfour @ Sep 18, 2009 - 9:15... Sep 19, 2009 - 7:50 AM

lagos QUOTE 1. a perspective customer anywhere in the wo... Sep 19, 2009 - 2:24 PM

lagos QUOTE 1. a perspective customer anywhere in the wo... Sep 19, 2009 - 2:24 PM

_Jim_ QUOTE (lagos @ Sep 19, 2009 - 2:24 P... Sep 19, 2009 - 6:36 PM

_Jim_ QUOTE (lagos @ Sep 19, 2009 - 2:24 P... Sep 19, 2009 - 6:36 PM

baktasht 6gtfour, thanks for the input. I always appreciate... Sep 19, 2009 - 10:33 PM

baktasht 6gtfour, thanks for the input. I always appreciate... Sep 19, 2009 - 10:33 PM

baktasht Pictures of the final version of the downpipe

* v... Sep 21, 2009 - 6:03 PM

baktasht Pictures of the final version of the downpipe

* v... Sep 21, 2009 - 6:03 PM

_Jim_ QUOTE (baktasht @ Sep 21, 2009 - 7:0... Sep 21, 2009 - 6:08 PM

_Jim_ QUOTE (baktasht @ Sep 21, 2009 - 7:0... Sep 21, 2009 - 6:08 PM

presure2 VERY nice. Is this the same basic setup that Texas... Sep 21, 2009 - 7:10 PM

presure2 VERY nice. Is this the same basic setup that Texas... Sep 21, 2009 - 7:10 PM

baktasht QUOTE (presure2 @ Sep 21, 2009 - 7:1... Sep 21, 2009 - 7:44 PM

baktasht QUOTE (presure2 @ Sep 21, 2009 - 7:1... Sep 21, 2009 - 7:44 PM

presure2 QUOTE (baktasht @ Sep 21, 2009 - 7:4... Sep 21, 2009 - 7:49 PM

presure2 QUOTE (baktasht @ Sep 21, 2009 - 7:4... Sep 21, 2009 - 7:49 PM

baktasht QUOTE (presure2 @ Sep 21, 2009 - 7:4... Sep 21, 2009 - 7:54 PM

baktasht QUOTE (presure2 @ Sep 21, 2009 - 7:4... Sep 21, 2009 - 7:54 PM

_Jim_ soon enough Sep 21, 2009 - 7:50 PM

_Jim_ soon enough Sep 21, 2009 - 7:50 PM

RUNNIN-LOW QUOTE (baktasht @ Sep 21, 2009 - 6:0... Sep 21, 2009 - 10:21 PM

RUNNIN-LOW QUOTE (baktasht @ Sep 21, 2009 - 6:0... Sep 21, 2009 - 10:21 PM

baktasht Added a few more pictures to the first post. Sep 25, 2009 - 1:10 PM

baktasht Added a few more pictures to the first post. Sep 25, 2009 - 1:10 PM

_Jim_ GORGEOUS Baktash, amazing as always. We will have... Sep 25, 2009 - 2:09 PM

_Jim_ GORGEOUS Baktash, amazing as always. We will have... Sep 25, 2009 - 2:09 PM

Terracar I think the point 6gtfour is trying to make he wou... Sep 25, 2009 - 3:16 PM

Terracar I think the point 6gtfour is trying to make he wou... Sep 25, 2009 - 3:16 PM

6gtfour QUOTE (Terracar @ Sep 25, 2009 - 4:1... Sep 26, 2009 - 5:22 PM

6gtfour QUOTE (Terracar @ Sep 25, 2009 - 4:1... Sep 26, 2009 - 5:22 PM

supershannon77 I'm really excited to see what my kind of magi... Sep 26, 2009 - 8:52 PM

supershannon77 I'm really excited to see what my kind of magi... Sep 26, 2009 - 8:52 PM

enderswift amazing quality! Sep 27, 2009 - 1:56 AM

enderswift amazing quality! Sep 27, 2009 - 1:56 AM

OOBE Those welds look as good as the ones on the GE T-7... Sep 27, 2009 - 2:06 AM

OOBE Those welds look as good as the ones on the GE T-7... Sep 27, 2009 - 2:06 AM

baktasht Will be posting the introductory sale this week. Sep 29, 2009 - 8:53 AM

baktasht Will be posting the introductory sale this week. Sep 29, 2009 - 8:53 AM

jeffrosie Will you be able to post this kit to U.K.?

Looks l... Sep 29, 2009 - 2:41 PM

jeffrosie Will you be able to post this kit to U.K.?

Looks l... Sep 29, 2009 - 2:41 PM

baktasht QUOTE (jeffrosie @ Sep 29, 2009 - 2... Sep 29, 2009 - 2:51 PM

baktasht QUOTE (jeffrosie @ Sep 29, 2009 - 2... Sep 29, 2009 - 2:51 PM

3WayStunna Well as wonderful as the pics are here, i just hav... Sep 29, 2009 - 3:14 PM

3WayStunna Well as wonderful as the pics are here, i just hav... Sep 29, 2009 - 3:14 PM

baktasht QUOTE (3WayStunna @ Sep 29, 2009 - 3... Sep 29, 2009 - 3:36 PM

baktasht QUOTE (3WayStunna @ Sep 29, 2009 - 3... Sep 29, 2009 - 3:36 PM

6gtfour MR2 Bolt-on Turbo Kit (300-625hp)

Retail Price: St... Sep 29, 2009 - 5:25 PM

6gtfour MR2 Bolt-on Turbo Kit (300-625hp)

Retail Price: St... Sep 29, 2009 - 5:25 PM

baktasht QUOTE (6gtfour @ Sep 29, 2009 - 5:25... Sep 29, 2009 - 5:51 PM

baktasht QUOTE (6gtfour @ Sep 29, 2009 - 5:25... Sep 29, 2009 - 5:51 PM

3WayStunna QUOTE (6gtfour @ Sep 29, 2009 - 6:25... Sep 29, 2009 - 11:52 PM

3WayStunna QUOTE (6gtfour @ Sep 29, 2009 - 6:25... Sep 29, 2009 - 11:52 PM

lagos QUOTE (6gtfour @ Sep 29, 2009 - 6:25... Sep 29, 2009 - 5:28 PM

lagos QUOTE (6gtfour @ Sep 29, 2009 - 6:25... Sep 29, 2009 - 5:28 PM

yellowchinaman This is a very nice down pipe. Definately a differ... Oct 1, 2009 - 2:16 PM

yellowchinaman This is a very nice down pipe. Definately a differ... Oct 1, 2009 - 2:16 PM

baktasht QUOTE (yellowchinaman @ Oct 1, 2009 - 2... Oct 1, 2009 - 2:24 PM

baktasht QUOTE (yellowchinaman @ Oct 1, 2009 - 2... Oct 1, 2009 - 2:24 PM

97celiman forgive my ignorance...what is the purpose of the ... Oct 1, 2009 - 2:36 PM

97celiman forgive my ignorance...what is the purpose of the ... Oct 1, 2009 - 2:36 PM

baktasht QUOTE (97celiman @ Oct 1, 2009 - 2:3... Oct 1, 2009 - 2:39 PM

baktasht QUOTE (97celiman @ Oct 1, 2009 - 2:3... Oct 1, 2009 - 2:39 PM

Detatch QUOTE (baktasht @ Sep 18, 2009 - 1:0... Oct 7, 2009 - 4:34 AM

Detatch QUOTE (baktasht @ Sep 18, 2009 - 1:0... Oct 7, 2009 - 4:34 AM

baktasht QUOTE (Detatch @ Oct 7, 2009 - 4:34 ... Oct 7, 2009 - 1:37 PM

baktasht QUOTE (Detatch @ Oct 7, 2009 - 4:34 ... Oct 7, 2009 - 1:37 PM

6gtfour any all wheel drive dyno runs with big boost yet o... Oct 21, 2009 - 10:42 PM

6gtfour any all wheel drive dyno runs with big boost yet o... Oct 21, 2009 - 10:42 PM

baktasht QUOTE (6gtfour @ Oct 21, 2009 - 10:4... Oct 25, 2009 - 11:24 PM

baktasht QUOTE (6gtfour @ Oct 21, 2009 - 10:4... Oct 25, 2009 - 11:24 PM  |

7 User(s) are reading this topic (7 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 25th, 2024 - 12:19 AM |