May 11, 2011 - 8:45 PM May 11, 2011 - 8:45 PM

|

|

Enthusiast    Joined Nov 18, '10 From montreal Currently Offline Reputation: 0 (0%) |

this is not something i suggest for people ,its just one way u can acheive extend your wiring

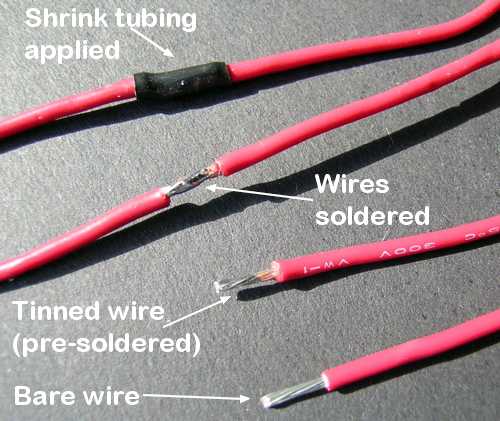

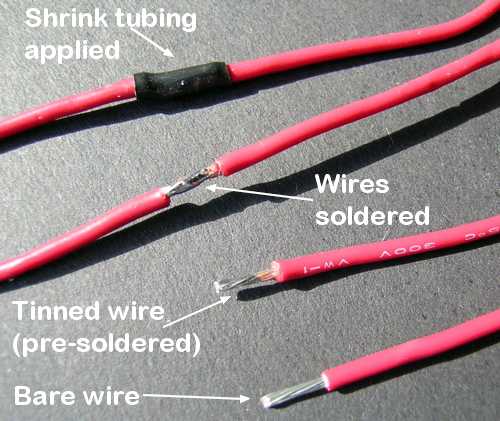

there is a lots of way to extend your wiring when you do your swap. this is one way, the one i did, whitout really being prepared. u can use this and form your own way to do it urself from there first you will need the following tool: ---one good wire splice tool..((sorry im french) (to easely took out the too many wire u will have to splice)) ---one pencil torch or a bic lighter ---cutter ---shrink tube to cover and securise each connection (dont use tape) ---welding pencil --- weldind metal ---use scott towell to clean your welding pencil and keep the same u will need some patience also how to weld: first , u will need to learn how to weld, its pretty easy thecnique for welding=when you have two wire u can connect them by twisting it or separate each wire inside from each other in form of star (what i did) and just reach them together and twist it around all wire together, its not important if its not hold tight at this point, your weld will tight it off whaen u weld its 3 point weld for those wire, one touch (1 or 2 sec) on top and one touch on each side of the wire whit your pencil weld and the wire weld stuff, if the stuff dont weld nicely on the wire, you can slide your pencil a little bit, dont put too much stuff cause ur wire gonna be too big and the resistance not appropriate and u will have trouble loom it back inside the hole of the firewall after cutting any wire be sure to place your rubber piece around the two side of wire...or you will have to cut it back for nothing, thats frustrating after joined the wire together and weld it, u just slide the rubber and heat it up, ( dont use the red flamme of the lighter or torch, u dont want to burn it, you want to heat it so that can shrink whitout burning, use the blue of your lighter or place ur rubber very near of your lighter) i did extend my wiring whit my engine and everything installed in the car first you start by unloom your wiring behin your charge cooler, until the end plug to cpu,  from there you will have to unloom all your old wiring from 5sfe get some mesure (i use something like 28 to 30 inch) 28 is minimum, and then cut all my old wire from old harness at the same lenght, after you will want to cut the tip of each side to prepared to be connected (unloom the tip)try to use the same color for your extention.but i ended up missing some wire for match color...i used other color wire or u can buy the missing one to match color. one good step to start the job is to seek where the jonction is, some wire alone , split in 3 at certain time, so extend the one wire not the 3 wire ... so, you will have to cut it to different place, check it and figure it out, the best way to start the job is to cut the wire (i think 2 or 3 ) that are alone from the harness red blue wire i think not sure) these wire are separate in the harness from all junction , so its a good way to start, cut those one, and extend it and put it a part ,on the side, each time you will cut and extend one wire at a time ,and put it on the side, whit the other wire ,that are already extend . so you dont get confuse, i suggest to cut one wire at a time and extend it and finish it and put it on the side before cutting another wire but, my friend who show me this have started the job by cutting a couple wire and identyfy the one whit same color, i think its better to do mit one at a time, abunch of wire will be in the way, so you maybe want to put those on the wiper, put the whipper up and put ur extra extended wire there, at this point some wire on the wiper, some on the right side are extend and in the middle still the wiring that is not extend the wire in the picture is the one that is good to start whit  just continue the process until its done, be sure to secure each connection when melting the rubber on it, it need to secure humidity, think of that the rest is looming back the harness together, im sure at this point you have your own idea how to do it lol  dont use that torch, lighter is better or pencil torch

This post has been edited by Needles: May 12, 2011 - 11:28 AM |

|

Replies

May 12, 2011 - 10:17 PM May 12, 2011 - 10:17 PM

|

|

|

Enthusiast      Joined May 29, '09 From Gainesville, FL Currently Offline Reputation: 17 (100%) |

Sounds neat, agreed on overkill =P

This post has been edited by rave2n: May 12, 2011 - 10:18 PM |

May 12, 2011 - 10:39 PM May 12, 2011 - 10:39 PM

|

|

Enthusiast    Joined Nov 18, '10 From montreal Currently Offline Reputation: 0 (0%) |

Sounds neat, agreed on overkill =P  this shrink tube should be larger , to be sure its cover and secure no need overkill soldering, if your wire gonn a broke, it gonna broke at another place than where you made your soldering one simple sold, and you cannot broke the wire whit pulling hard whit your two arm This post has been edited by Needles: May 12, 2011 - 10:43 PM |

Posts in this topic

Needles How to extend your harness May 11, 2011 - 8:45 PM

Needles How to extend your harness May 11, 2011 - 8:45 PM

brenton1919 i dont recommend solder or wire welding, over time... May 12, 2011 - 6:12 AM

brenton1919 i dont recommend solder or wire welding, over time... May 12, 2011 - 6:12 AM

nsxtypeR What do you recommend then? Since soldering is the... May 12, 2011 - 6:33 AM

nsxtypeR What do you recommend then? Since soldering is the... May 12, 2011 - 6:33 AM

brenton1919 QUOTE (nsxtypeR @ May 12, 2011 - 7:3... May 12, 2011 - 7:50 AM

brenton1919 QUOTE (nsxtypeR @ May 12, 2011 - 7:3... May 12, 2011 - 7:50 AM

Needles QUOTE (brenton1919 @ May 12, 2011 - 7... May 12, 2011 - 11:25 AM

Needles QUOTE (brenton1919 @ May 12, 2011 - 7... May 12, 2011 - 11:25 AM

rave2n QUOTE (brenton1919 @ May 12, 2011 - 7... May 12, 2011 - 4:44 PM

rave2n QUOTE (brenton1919 @ May 12, 2011 - 7... May 12, 2011 - 4:44 PM

lagos Soldering is perfectly fine and much better than n... May 12, 2011 - 1:36 PM

lagos Soldering is perfectly fine and much better than n... May 12, 2011 - 1:36 PM

njccmd2002 nah the best way to solder is to get the wires tog... May 12, 2011 - 10:14 PM

njccmd2002 nah the best way to solder is to get the wires tog... May 12, 2011 - 10:14 PM

delusionz I interlock the strands of wire then give it a lit... May 13, 2011 - 4:40 AM

delusionz I interlock the strands of wire then give it a lit... May 13, 2011 - 4:40 AM

delusionz if you do rave2n's way you gotta be extra care... May 13, 2011 - 4:45 AM

delusionz if you do rave2n's way you gotta be extra care... May 13, 2011 - 4:45 AM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 27th, 2024 - 3:53 AM |