Aug 11, 2010 - 8:36 PM Aug 11, 2010 - 8:36 PM

|

|

|

Enthusiast   Joined Dec 30, '09 From Wilmington, NC Currently Offline Reputation: 1 (100%) |

So first off, I've been using this forum a lot for reference and information in the past few months and it's a great tool for anyone who owns a Celica, so thanks to everyone who puts up good information.

I'm in the process of rebuilding my 7afe. It had 136000 on it when i pulled it out, but it hardly looked like 30000 were on it once i opened it up except for some oil sludge. I purchased a V-5 vortech f-trim to put on after i get the car running again, but I figured I'd share a few pics of the rebuild and update some more when I get to the fun stuff. Pulled the engine in Feb, (i travel around the world a lot, so I've been off and on with this project) brought block and head to my machinist. Block only needed a fine hone. Head didn't need much, but had a valve job done just to freshen it up since 16 yrs on the valve springs is probably enough. Started rebuilding on Wednesday and relaxed today, I might finish rebuilding tomorrow.  Block painted and piston one reinstalled.   nice picture of the little 7a rods  head and cams installed, water pump on  timing belt installed This post has been edited by al94st: Nov 1, 2011 - 5:35 AM |

|

Replies

Jul 10, 2011 - 7:13 PM Jul 10, 2011 - 7:13 PM

|

|

|

Enthusiast   Joined Dec 30, '09 From Wilmington, NC Currently Offline Reputation: 1 (100%) |

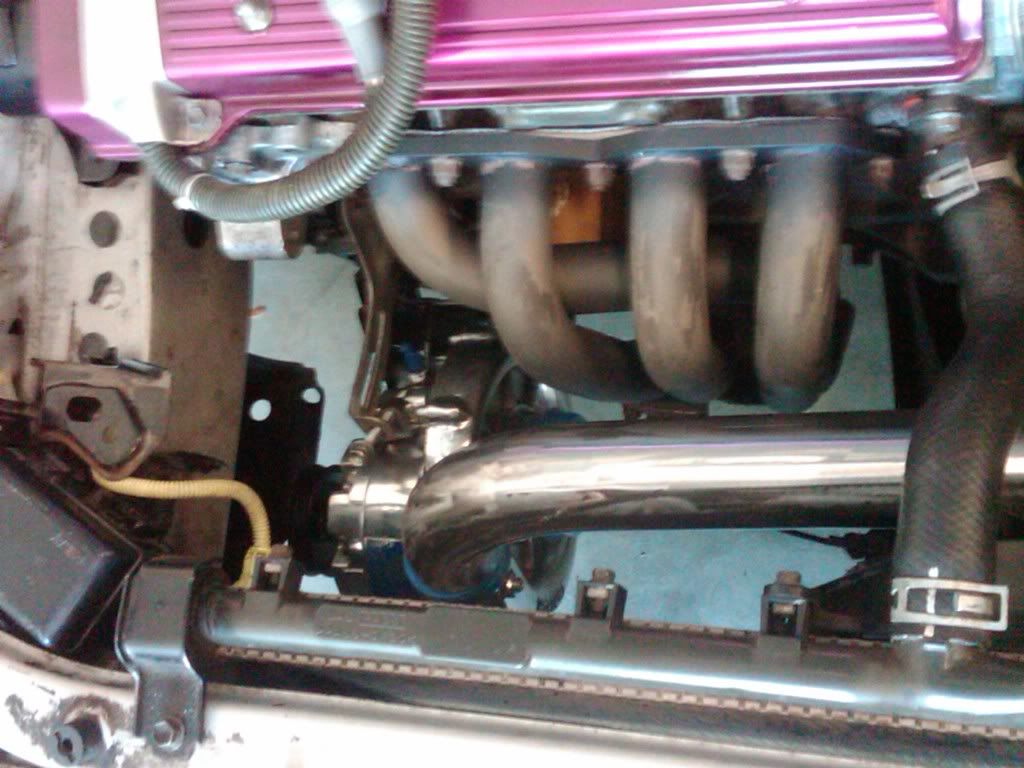

So like I said I decided to make a new bracket and ditch my A/C. I spent the whole weekend fabricating crap, but it's almost done. I'm waiting on the silicon couplers for my intake piping and then I'll be able to hook it all up.

First I started with some 3/16 steel. 3/16 only because that's the limit for my fluxcore welder (also why all my welds are ground down) So I cut up some pieces like so.  Before that (last weekend) I welded up some steel on the A/C bracket so eventaully the supercharger bracket could be welded to that. Yea I could've made it so it bolted to the A/C bracket...but that would've been a real pain.  So after some welding, grinding and more grinding I had something like  Then I welded that up to the A/C bracket after a lot of measuring and in and out of the car crap  Then I messed around added another piece to the bracket for more stability since it's only 3/16" I figured better safe than sorry. The picture is crappy and doesnt really do justice of the time it took, but w/e.  Then after that I started make up piping. 2.5" Hooker J pipes...cut..weld...grind..cut..weld..grind..grind..grind. I also welded up my BOV flange, but I didnt take pics. It's not alumium its mild steel, but looks shiny from hitting it with a 120grit pad on my grinder.   I installed the Wlabro pump like a month ago...and I think I have the right length belt now after realizing the one I got yesterday was too long. So once I get the couplers I just have to put everything in, connect the oil lines, which are ready to go, and reinstall the 2bar map and injectors. |

Posts in this topic

al94st 7a rebuild and Vortech Supercharger Aug 11, 2010 - 8:36 PM

al94st 7a rebuild and Vortech Supercharger Aug 11, 2010 - 8:36 PM

celica74 wow. very unique. Have never heard of anyone putti... Aug 12, 2010 - 5:18 PM

celica74 wow. very unique. Have never heard of anyone putti... Aug 12, 2010 - 5:18 PM

95celicastLSR i have thought about this because of instant boost... Aug 14, 2010 - 9:22 PM

95celicastLSR i have thought about this because of instant boost... Aug 14, 2010 - 9:22 PM

Johnnyny if you want some low rpm power get some cams work ... Aug 14, 2010 - 9:44 PM

Johnnyny if you want some low rpm power get some cams work ... Aug 14, 2010 - 9:44 PM

al94st As far as I've seen the stock cams are designe... Aug 15, 2010 - 8:58 AM

al94st As far as I've seen the stock cams are designe... Aug 15, 2010 - 8:58 AM

SwissFerdi I'm very interested to see how this'll tur... Aug 15, 2010 - 9:27 AM

SwissFerdi I'm very interested to see how this'll tur... Aug 15, 2010 - 9:27 AM

Nartanian This should prove to be interesting. Aug 15, 2010 - 11:36 AM

Nartanian This should prove to be interesting. Aug 15, 2010 - 11:36 AM

JoKeRkId613 the v5 might be a little big for the 7a, but props... Aug 16, 2010 - 12:30 PM

JoKeRkId613 the v5 might be a little big for the 7a, but props... Aug 16, 2010 - 12:30 PM

al94st Quick update. Yesterday I started and timed the e... Aug 22, 2010 - 7:37 AM

al94st Quick update. Yesterday I started and timed the e... Aug 22, 2010 - 7:37 AM

Tom_SS2 i heard a 7A-GZE had been done before using pars f... Aug 22, 2010 - 8:17 AM

Tom_SS2 i heard a 7A-GZE had been done before using pars f... Aug 22, 2010 - 8:17 AM

delusionz QUOTE (Tom_SS2 @ Aug 23, 2010 - 1:17... Apr 21, 2011 - 12:14 AM

delusionz QUOTE (Tom_SS2 @ Aug 23, 2010 - 1:17... Apr 21, 2011 - 12:14 AM

JuMPiiN Nice vid find, GL with your build bro, this is def... Aug 22, 2010 - 8:43 AM

JuMPiiN Nice vid find, GL with your build bro, this is def... Aug 22, 2010 - 8:43 AM

cheela very interesting indeed. I'll be peeking into ... Aug 22, 2010 - 11:39 AM

cheela very interesting indeed. I'll be peeking into ... Aug 22, 2010 - 11:39 AM

al94st I've put about 90 miles on it since rebuild. ... Sep 2, 2010 - 7:43 AM

al94st I've put about 90 miles on it since rebuild. ... Sep 2, 2010 - 7:43 AM

al94st Quick update on this. Haven't given up on the... Oct 28, 2010 - 10:11 PM

al94st Quick update on this. Haven't given up on the... Oct 28, 2010 - 10:11 PM

celica74 What part of NC? im located just outside of raleig... Oct 30, 2010 - 5:33 PM

celica74 What part of NC? im located just outside of raleig... Oct 30, 2010 - 5:33 PM

al94st Wilmington Oct 30, 2010 - 9:31 PM

al94st Wilmington Oct 30, 2010 - 9:31 PM

HectortheRican Nice choice of wheels! I dunno how to explain ... Nov 2, 2010 - 6:00 PM

HectortheRican Nice choice of wheels! I dunno how to explain ... Nov 2, 2010 - 6:00 PM

al94st QUOTE (HectortheRican @ Nov 2, 2010 - 6... Nov 2, 2010 - 6:29 PM

al94st QUOTE (HectortheRican @ Nov 2, 2010 - 6... Nov 2, 2010 - 6:29 PM

HectortheRican QUOTE (al94st @ Nov 2, 2010 - 5:29 P... Nov 2, 2010 - 8:45 PM

HectortheRican QUOTE (al94st @ Nov 2, 2010 - 5:29 P... Nov 2, 2010 - 8:45 PM

celica74 might have to take the 2 1/2 hour drive to check i... Nov 2, 2010 - 6:05 PM

celica74 might have to take the 2 1/2 hour drive to check i... Nov 2, 2010 - 6:05 PM

GriffGirl 2.5" exhaust is going to be a tad big for a 7... Nov 11, 2010 - 3:13 PM

GriffGirl 2.5" exhaust is going to be a tad big for a 7... Nov 11, 2010 - 3:13 PM

al94st I actually just redid the exhaust to make the car ... Nov 11, 2010 - 3:27 PM

al94st I actually just redid the exhaust to make the car ... Nov 11, 2010 - 3:27 PM

al94st Finally getting back to this project, bought supra... Mar 5, 2011 - 11:22 PM

al94st Finally getting back to this project, bought supra... Mar 5, 2011 - 11:22 PM

k-weaver QUOTE (al94st @ Mar 6, 2011 - 5:22 A... Mar 6, 2011 - 9:30 PM

k-weaver QUOTE (al94st @ Mar 6, 2011 - 5:22 A... Mar 6, 2011 - 9:30 PM

NYp8tBaller07 awesome work, can not wait to see how this ends up Mar 6, 2011 - 1:13 AM

NYp8tBaller07 awesome work, can not wait to see how this ends up Mar 6, 2011 - 1:13 AM

al94st Having trouble locating a good oil feed adapter bl... Mar 18, 2011 - 7:34 PM

al94st Having trouble locating a good oil feed adapter bl... Mar 18, 2011 - 7:34 PM

al94st Oil pan painted and oil return installed...10an

... Mar 22, 2011 - 8:49 PM

al94st Oil pan painted and oil return installed...10an

... Mar 22, 2011 - 8:49 PM

al94st Well, my walbro fuel pump, stoich gauge, breather ... Mar 31, 2011 - 7:58 PM

al94st Well, my walbro fuel pump, stoich gauge, breather ... Mar 31, 2011 - 7:58 PM

al94st Finally got my gauge holder finished and gauges al... Apr 6, 2011 - 6:49 PM

al94st Finally got my gauge holder finished and gauges al... Apr 6, 2011 - 6:49 PM

Smaay QUOTE (al94st @ Apr 6, 2011 - 4:49 P... May 31, 2011 - 11:04 AM

Smaay QUOTE (al94st @ Apr 6, 2011 - 4:49 P... May 31, 2011 - 11:04 AM

al94st just so you guys get an idea of where this bad boy... Apr 8, 2011 - 8:14 PM

al94st just so you guys get an idea of where this bad boy... Apr 8, 2011 - 8:14 PM

SwissFerdi Wow. Best of luck. The awesomeness is strong in th... Apr 8, 2011 - 9:32 PM

SwissFerdi Wow. Best of luck. The awesomeness is strong in th... Apr 8, 2011 - 9:32 PM

al94st hard at work..should have it mounted soon... Apr 17, 2011 - 7:45 AM

al94st hard at work..should have it mounted soon... Apr 17, 2011 - 7:45 AM

al94st Mounts made up (unfortunately the process took for... Apr 20, 2011 - 7:49 PM

al94st Mounts made up (unfortunately the process took for... Apr 20, 2011 - 7:49 PM

al94st Yea the 7a is pretty slow. The blower on that car... Apr 21, 2011 - 5:18 AM

al94st Yea the 7a is pretty slow. The blower on that car... Apr 21, 2011 - 5:18 AM

OOBE Keep on, bro. Our cars are unique. It's not ab... Apr 26, 2011 - 7:13 PM

OOBE Keep on, bro. Our cars are unique. It's not ab... Apr 26, 2011 - 7:13 PM

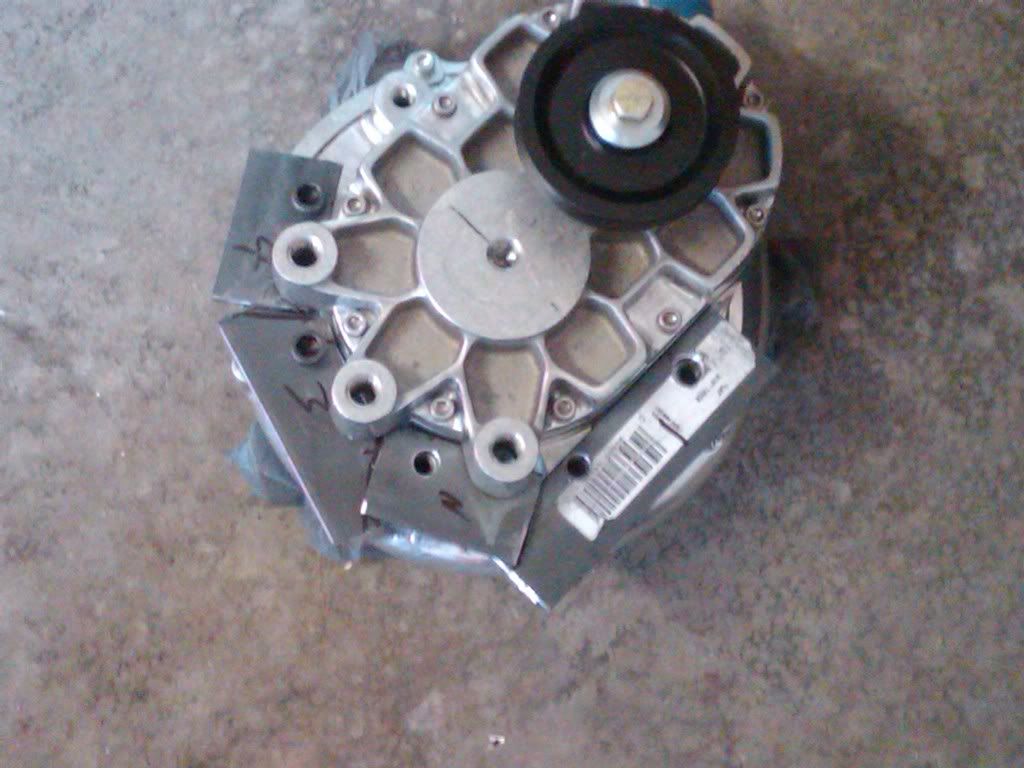

al94st I got an idler pulley and found the right belt len... May 3, 2011 - 6:15 AM

al94st I got an idler pulley and found the right belt len... May 3, 2011 - 6:15 AM

lagos Really cool project you got going here! May 3, 2011 - 11:35 AM

lagos Really cool project you got going here! May 3, 2011 - 11:35 AM

al94st Thanks Lagos

Things left to do:

Mount breather c... May 29, 2011 - 10:58 PM

al94st Thanks Lagos

Things left to do:

Mount breather c... May 29, 2011 - 10:58 PM

PolliS_5S-FE do the ebay headers get hotter than stock? May 29, 2011 - 11:22 PM

PolliS_5S-FE do the ebay headers get hotter than stock? May 29, 2011 - 11:22 PM

al94st It seems to be pretty hot and at least the stock m... May 30, 2011 - 6:46 AM

al94st It seems to be pretty hot and at least the stock m... May 30, 2011 - 6:46 AM

al94st It's really not junk, I wish people would stop... May 31, 2011 - 8:55 PM

al94st It's really not junk, I wish people would stop... May 31, 2011 - 8:55 PM

TerBeau true statement!!!^^^^^ looks good my f... Jul 7, 2011 - 8:46 PM

TerBeau true statement!!!^^^^^ looks good my f... Jul 7, 2011 - 8:46 PM

al94st Thanks, dedicating this weekend to trying to finis... Jul 7, 2011 - 8:57 PM

al94st Thanks, dedicating this weekend to trying to finis... Jul 7, 2011 - 8:57 PM

celica-s http://www.sd-performance.com/eng/showProduct.asp?... Jul 11, 2011 - 1:44 AM

celica-s http://www.sd-performance.com/eng/showProduct.asp?... Jul 11, 2011 - 1:44 AM

al94st Vortech charged 7afe alive and crusining. It... Jul 16, 2011 - 6:14 PM

al94st Vortech charged 7afe alive and crusining. It... Jul 16, 2011 - 6:14 PM

JuMPiiN QUOTE (al94st @ Jul 16, 2011 - 6:14 ... Jul 16, 2011 - 6:51 PM

JuMPiiN QUOTE (al94st @ Jul 16, 2011 - 6:14 ... Jul 16, 2011 - 6:51 PM

SwissFerdi Congratulations, I'm anxious for the video, an... Jul 16, 2011 - 7:55 PM

SwissFerdi Congratulations, I'm anxious for the video, an... Jul 16, 2011 - 7:55 PM

al94st Just need to get my header wrap on there.

Thanks... Jul 18, 2011 - 8:33 PM

al94st Just need to get my header wrap on there.

Thanks... Jul 18, 2011 - 8:33 PM

al94st OK got this thing on the dyno today. Numbers aren... Jul 20, 2011 - 3:07 PM

al94st OK got this thing on the dyno today. Numbers aren... Jul 20, 2011 - 3:07 PM

presure2 Thats about what id expect without an intercooler ... Jul 20, 2011 - 6:52 PM

presure2 Thats about what id expect without an intercooler ... Jul 20, 2011 - 6:52 PM

al94st QUOTE (presure2 @ Jul 20, 2011 - 7:5... Jul 20, 2011 - 7:22 PM

al94st QUOTE (presure2 @ Jul 20, 2011 - 7:5... Jul 20, 2011 - 7:22 PM

al94st I switched to a 2.62" pulley today from a 3.2... Jul 22, 2011 - 7:07 PM

al94st I switched to a 2.62" pulley today from a 3.2... Jul 22, 2011 - 7:07 PM

PolliS_5S-FE so its basically like a stock 5s, apart from torqu... Jul 25, 2011 - 12:10 AM

PolliS_5S-FE so its basically like a stock 5s, apart from torqu... Jul 25, 2011 - 12:10 AM

al94st QUOTE (PolliS_5S-FE @ Jul 25, 2011 ... Jul 25, 2011 - 5:15 AM

al94st QUOTE (PolliS_5S-FE @ Jul 25, 2011 ... Jul 25, 2011 - 5:15 AM

Keiri Just re-read the entire thread AJ and you have don... Jul 25, 2011 - 7:51 AM

Keiri Just re-read the entire thread AJ and you have don... Jul 25, 2011 - 7:51 AM

al94st QUOTE (Keiri @ Jul 25, 2011 - 8:51 A... Jul 25, 2011 - 5:11 PM

al94st QUOTE (Keiri @ Jul 25, 2011 - 8:51 A... Jul 25, 2011 - 5:11 PM

Cuts_the_Pilot I like this, its different.

As you know getting th... Jul 25, 2011 - 8:40 AM

Cuts_the_Pilot I like this, its different.

As you know getting th... Jul 25, 2011 - 8:40 AM

stephen_lee it actually looks like the stock tune is really ni... Jul 25, 2011 - 11:51 AM

stephen_lee it actually looks like the stock tune is really ni... Jul 25, 2011 - 11:51 AM

presure2 Nice!

Anything to keep the heat off that charg... Jul 25, 2011 - 6:58 PM

presure2 Nice!

Anything to keep the heat off that charg... Jul 25, 2011 - 6:58 PM

celica-s very nice install, i may ask, will a stock charger... Jul 25, 2011 - 9:12 PM

celica-s very nice install, i may ask, will a stock charger... Jul 25, 2011 - 9:12 PM

PolliS_5S-FE oh sorry i thought that was flywheel hp, very nice... Jul 26, 2011 - 4:35 AM

PolliS_5S-FE oh sorry i thought that was flywheel hp, very nice... Jul 26, 2011 - 4:35 AM

al94st QUOTE (celica-s @ Jul 25, 2011 - 9... Jul 26, 2011 - 5:08 AM

al94st QUOTE (celica-s @ Jul 25, 2011 - 9... Jul 26, 2011 - 5:08 AM

celica-s a 205 bonnet and a top mount intercooler should be... Aug 3, 2011 - 1:35 AM

celica-s a 205 bonnet and a top mount intercooler should be... Aug 3, 2011 - 1:35 AM

Cuts_the_Pilot a 4a blower would probably be a reasonable match f... Aug 3, 2011 - 3:07 AM

Cuts_the_Pilot a 4a blower would probably be a reasonable match f... Aug 3, 2011 - 3:07 AM

Johnnyny this is great keep it up Aug 3, 2011 - 3:10 AM

Johnnyny this is great keep it up Aug 3, 2011 - 3:10 AM

stephen_lee the 7a runs around 15:1 idle and cruise. more than... Aug 3, 2011 - 9:28 PM

stephen_lee the 7a runs around 15:1 idle and cruise. more than... Aug 3, 2011 - 9:28 PM

al94st Got my front mount aftercooler, at some point I... Aug 10, 2011 - 11:51 AM

al94st Got my front mount aftercooler, at some point I... Aug 10, 2011 - 11:51 AM

al94st FMIC and Half Radiator installed. For any 7afe gu... Sep 4, 2011 - 7:31 PM

al94st FMIC and Half Radiator installed. For any 7afe gu... Sep 4, 2011 - 7:31 PM

cheela been waiting for someone to start a thread like th... Sep 4, 2011 - 7:43 PM

cheela been waiting for someone to start a thread like th... Sep 4, 2011 - 7:43 PM

zoik i hope to see a sleeper version of a compressed 7a... Sep 6, 2011 - 12:00 PM

zoik i hope to see a sleeper version of a compressed 7a... Sep 6, 2011 - 12:00 PM

playr158 There is so much win in this thread!! Gre... Sep 6, 2011 - 12:27 PM

playr158 There is so much win in this thread!! Gre... Sep 6, 2011 - 12:27 PM

al94st QUOTE (cheela @ Sep 4, 2011 - 7:43 P... Sep 10, 2011 - 6:06 PM

al94st QUOTE (cheela @ Sep 4, 2011 - 7:43 P... Sep 10, 2011 - 6:06 PM

presure2 good to see the civic 1/2 rad fits well in the bay... Sep 11, 2011 - 8:04 AM

presure2 good to see the civic 1/2 rad fits well in the bay... Sep 11, 2011 - 8:04 AM

al94st Thanks, I'm kind of surprised no one has tried... Sep 11, 2011 - 7:04 PM

al94st Thanks, I'm kind of surprised no one has tried... Sep 11, 2011 - 7:04 PM

BonzaiCelica QUOTE (presure2 @ Sep 11, 2011 - 8:0... Sep 11, 2011 - 8:18 PM

BonzaiCelica QUOTE (presure2 @ Sep 11, 2011 - 8:0... Sep 11, 2011 - 8:18 PM

al94st Nah, I can take more if needed though. You can ge... Sep 11, 2011 - 10:03 PM

al94st Nah, I can take more if needed though. You can ge... Sep 11, 2011 - 10:03 PM

SwissFerdi Any plans of throwing an intercooler on soon? I lo... Sep 11, 2011 - 10:15 PM

SwissFerdi Any plans of throwing an intercooler on soon? I lo... Sep 11, 2011 - 10:15 PM

matts94celica QUOTE (SwissFerdi @ Sep 11, 2011 - 10... Sep 12, 2011 - 3:45 AM

matts94celica QUOTE (SwissFerdi @ Sep 11, 2011 - 10... Sep 12, 2011 - 3:45 AM

SwissFerdi QUOTE (matts94celica @ Sep 12, 2011 - 4... Sep 12, 2011 - 6:36 PM

SwissFerdi QUOTE (matts94celica @ Sep 12, 2011 - 4... Sep 12, 2011 - 6:36 PM

Shoker Really nice work! Sep 12, 2011 - 1:06 AM

Shoker Really nice work! Sep 12, 2011 - 1:06 AM

BonzaiCelica more pics of your radiator set up please Sep 12, 2011 - 5:36 AM

BonzaiCelica more pics of your radiator set up please Sep 12, 2011 - 5:36 AM

matts94celica Yeah it was hiding in the pic. Hopefully we can se... Sep 13, 2011 - 3:06 AM

matts94celica Yeah it was hiding in the pic. Hopefully we can se... Sep 13, 2011 - 3:06 AM

al94st QUOTE (BonzaiCelica @ Sep 12, 2011 - 5... Sep 13, 2011 - 5:09 AM

al94st QUOTE (BonzaiCelica @ Sep 12, 2011 - 5... Sep 13, 2011 - 5:09 AM

matts94celica I wish I could get mine dyno'd before and afte... Sep 13, 2011 - 6:20 AM

matts94celica I wish I could get mine dyno'd before and afte... Sep 13, 2011 - 6:20 AM

bsamps4 AJ, like the intercooler set up! Exactly what ... Sep 16, 2011 - 9:29 PM

bsamps4 AJ, like the intercooler set up! Exactly what ... Sep 16, 2011 - 9:29 PM

al94st QUOTE (BonzaiCelica @ Sep 12, 2011 - 5... Sep 18, 2011 - 10:58 AM

al94st QUOTE (BonzaiCelica @ Sep 12, 2011 - 5... Sep 18, 2011 - 10:58 AM

matts94celica QUOTE (al94st @ Sep 18, 2011 - 11:58... Sep 20, 2011 - 7:59 PM

matts94celica QUOTE (al94st @ Sep 18, 2011 - 11:58... Sep 20, 2011 - 7:59 PM

bsamps4 I wanna see pics of the aftercooler! Sep 19, 2011 - 10:05 AM

bsamps4 I wanna see pics of the aftercooler! Sep 19, 2011 - 10:05 AM

al94st Well ran my first auto-x today. It was fun, but I... Sep 25, 2011 - 2:55 PM

al94st Well ran my first auto-x today. It was fun, but I... Sep 25, 2011 - 2:55 PM

al94st Well, I doubt I'm going to be selling this bab... Sep 29, 2011 - 9:08 PM

al94st Well, I doubt I'm going to be selling this bab... Sep 29, 2011 - 9:08 PM

Neon90424 QUOTE (al94st @ Sep 29, 2011 - 10:08... Sep 30, 2011 - 2:35 PM

Neon90424 QUOTE (al94st @ Sep 29, 2011 - 10:08... Sep 30, 2011 - 2:35 PM

bsamps4 Twin Charge FTMFW! Sep 29, 2011 - 9:17 PM

bsamps4 Twin Charge FTMFW! Sep 29, 2011 - 9:17 PM

SwissFerdi Why not try to twin-charge the 7A?

Glad to see y... Sep 30, 2011 - 12:02 AM

SwissFerdi Why not try to twin-charge the 7A?

Glad to see y... Sep 30, 2011 - 12:02 AM

matts94celica You would have to fully build the 7afe and get a b... Sep 30, 2011 - 2:36 AM

matts94celica You would have to fully build the 7afe and get a b... Sep 30, 2011 - 2:36 AM

al94st QUOTE (SwissFerdi @ Sep 30, 2011 - 1... Sep 30, 2011 - 5:47 AM

al94st QUOTE (SwissFerdi @ Sep 30, 2011 - 1... Sep 30, 2011 - 5:47 AM

matts94celica Well it don't matter what you placed as long a... Oct 2, 2011 - 9:31 PM

matts94celica Well it don't matter what you placed as long a... Oct 2, 2011 - 9:31 PM

al94st Nah, no decisions made as of yet. Just preregiste... Oct 3, 2011 - 7:00 PM

al94st Nah, no decisions made as of yet. Just preregiste... Oct 3, 2011 - 7:00 PM  |

18 User(s) are reading this topic (18 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 26th, 2024 - 10:32 AM |