May 20, 2012 - 7:36 PM May 20, 2012 - 7:36 PM

|

|

|

Enthusiast      Joined Aug 2, '05 From Guam Currently Offline Reputation: 15 (100%) |

INNER/OUTER TIE ROD REMOVAL/REPLACE

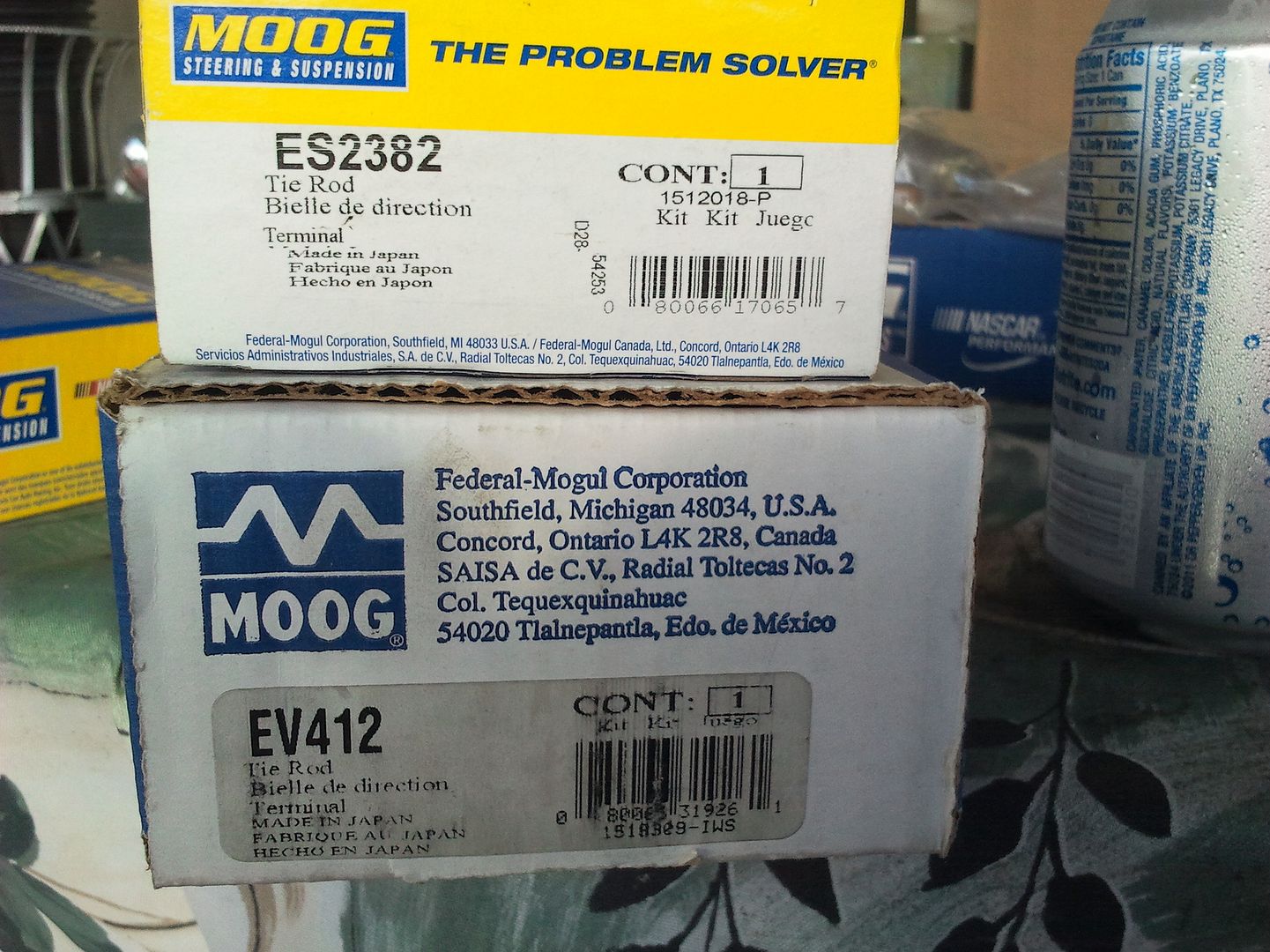

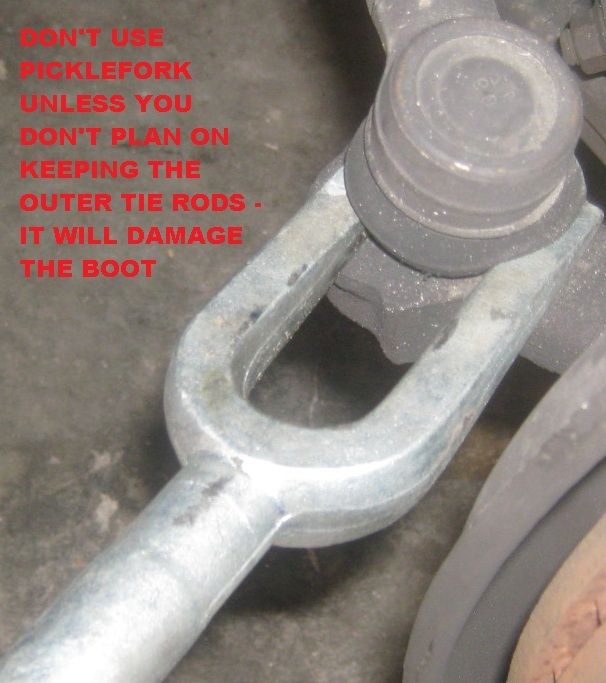

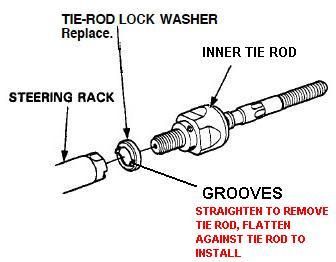

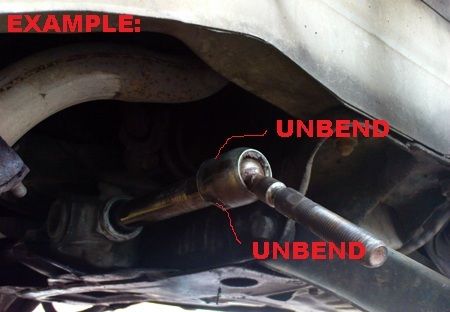

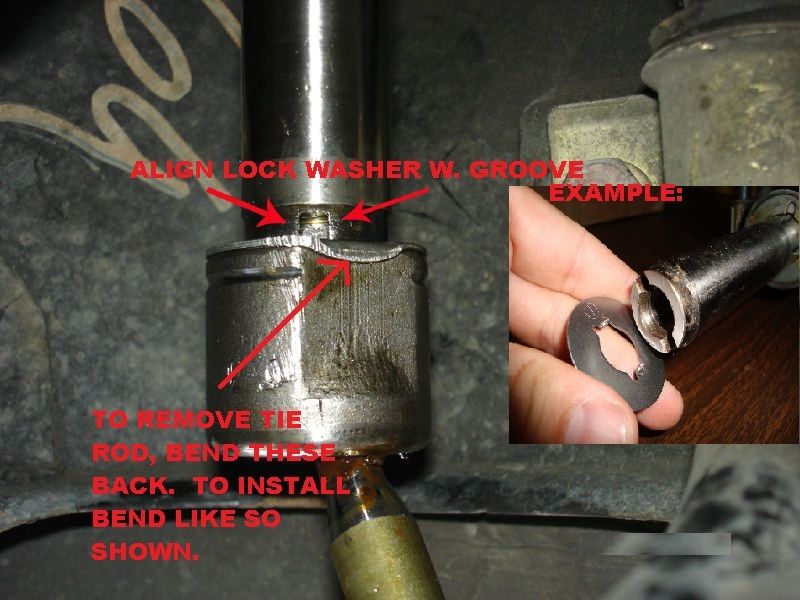

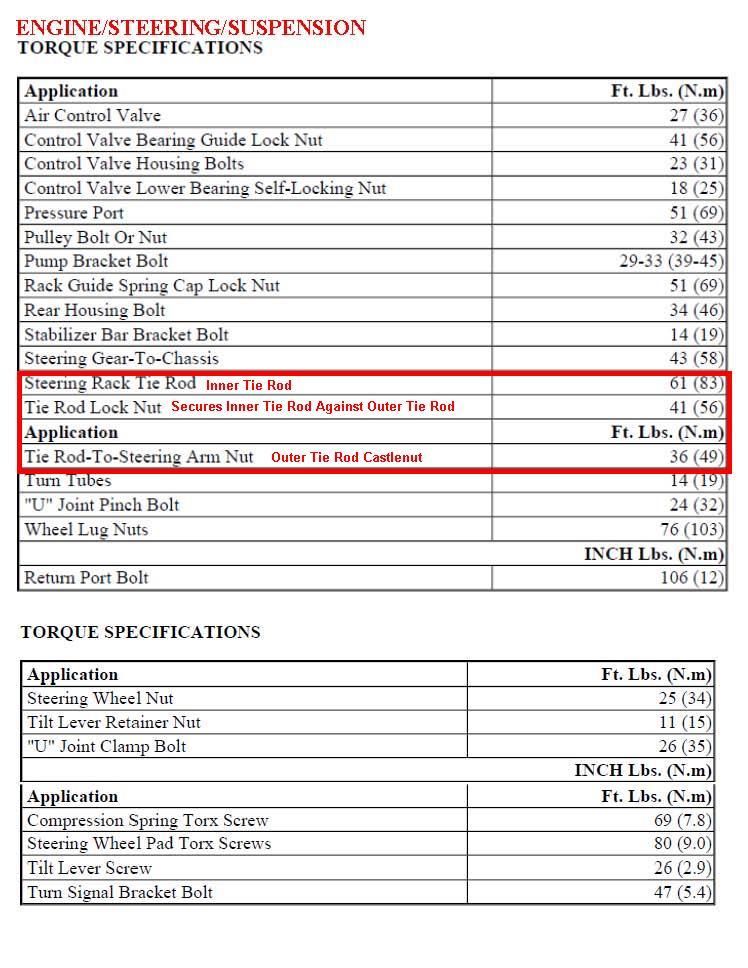

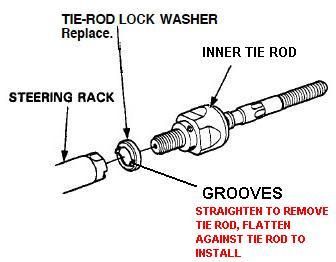

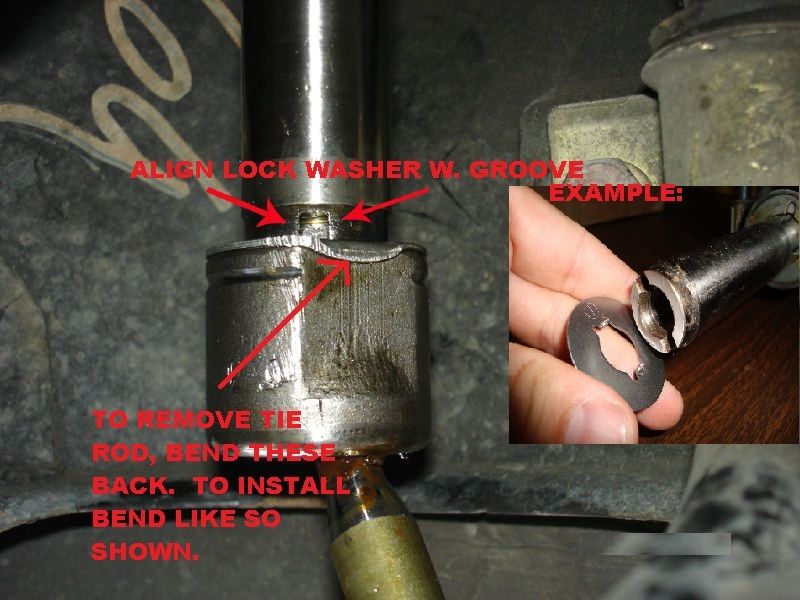

TOOLS NEEDED: -Jack - to jack up car -Jack Stands - to hold up car -Ratchet/Long Ratchet or Breaker Bar and correct socket for Wheel Lugnuts and Outer Tie Rod Castlenut. -Hammer - to hammer -Puller - for outer tie rod, if hammering the side knuckle does not work. -WD40 or PBBLaster whatever - To loosen stuff -Adjustable Wrench - To remove lock nut -Screwdriver - to remove clamps or to straighten out lockwasher for removal. -Pliers and/or Channel locks - to remove cotter pin and rack boot clamps, also used it to flatten lock washer -Inner Tie Rod Tool - to remove and install inner tie rods -Torque Wrench - to torque to spec -Inner or Outer Tie Rod Parts (Whichever you are changing, in my case I purchased both MOOG Inner and Outer Tie Rods, this model does not require grease fittings) -lithium multigrease for the pivot ball inner tie rod - for extra greasing -I think thats all i remembered that I used  MOOG Parts I Bought:      Reference Videos - Pretty Much Exactly Like Our Celicas: Inner Tie Rod Example Video Outer Tie Rod Example Video STEPS: (Random Actual Pics, Or Concept/Example Illustrations:) This is for Remove/Install of Inner/Outer Tie Rods while the Steering Rack is still on the vehicle. 1. Secure vehicle so that it does not roll 2. Jack Up Car 3. Put on Jack Stands 4. Take Off Wheel 5. You can move steering Wheel to the correct side to let it come out more to your side to make it easier to work on. 6. I'd probably take off the lock nut by this time because its still bolted on, you can remove this with an adjustable wrench, sometimes you have to hit your wrench with a hammer to get it loose or spray oil on it. NOTE: You just have to get a bit loose so you still know where the position is. PB Blaster works well.  7. Take Off CotterPin from Outer Tie Rod and then,  8. Take Off Castlenut from Outer Tie Rod (I think it was a 17mm or 19mm)  9. You can hit the side of the knuckle with a hammer to let loose the outer tie rod, if it doesn't work, use a puller.  10. Don't hit the outer tie rod ball joint stud, you might damage it if you plan to reuse and if you are planning to just change the inner tie rod. NOTE: Picklefork will damage the boot so I go against this unless you don't need the old outer tie rod.  11. Once the outer tie rod is off either mark, measure the distance of the current position of the outer tie rod. 12. Common technique IF the original and new tie rods are same length is note the positions before spinning the tie rod off, count how many times it takes to back it off to remove, you can do the same to install (i counted by noticing the position of the stud north or south when I took it off and remembering that when I install back). Sometimes tie rod replacements are not the same length or specs. (this will make it easier to get it close to put it back on to almost the same position and makes it easier for the alignment shop).   13. Once you are confident and decided how to mark your the position for reinstalling it back. Take off the locknut, (because you already marked, measured, or counted), remove the steering rack boot, there are different types of clamps, common sense how to remove them. 14. You can now pull the boot off - be careful.  15. Here you will see the inner tie rod by itself. There is this lock washer You need to get this washer flattened against the rod flats back to , hit it with anything, I used a screwdriver whatever I could get in there to make it flat. This will make the inner tie rod removable.     16. Now, that the washer is flattened back to normal, you take your inner tie rod tool and line it up correctly to the 2 flats on the tie rod. use a 1/2 ratchet to loosen it. I found that if you can't get the washer bent back, you can force it loose by turning left with the inner tie rod tool and the 1/2, eventually that washer will give in. **There are different Inner Tie Rod Tools: a. I've used the Napa/KD Tools one where it is a flat on one side, and the other side is a bolt, which you can adjust and tighten to basically make the other flat side. Kinda universal but not the easiest or most reassuring tool because of aligning it was the most inconvenient part. b. There is the changeable crows foot adapters one which I find more commonly and preferredly used. There are different sizes some sets more complete than others. c. There is a universal type which have good and bad reviews because of the fitment. d. There are the hex type tools that are for tie rods that do not have 2 flats. < not relative to us.   17. Once it loosened and off, you can now take off the inner tie rod and locking washer. Reinstallation: Review Torque Specs - Personally don't like those numbers, dont sound tight enough, but the dealer should know better than me yea?  NOTE: Some people like to use blue loctite on the inner tie rod threads - its your choice but not mandatory.  1. Put on the locking washer first, you'll notice it lines up to the grooves on the rack. Make sure it stays in this position while you hold it with one hand and the other hand screws back in the new inner tie rod.   2. At this point use the inner tie rod tool to tighten it to OEM spec (61 ft lbs)  3. Smash the locking washer against the tie rod flats again (Tight fit). I used pliers/channel lock to bite and smash it flat. **Make sure you also grease inner tie rod pivot ball joint. Use Lithium Multi-purpose grease. I've seen semi gold clear ones from grease gun cartridges and also the nice white colored ones which i found were used already in the MOOG ones, might as well grease it up more.  4. Reinstall Rack Boot, you can also use Zip Ties, if the old clamps are damaged. 5. Put back on the outer tie rod locking nut. Install it all the way back to give the outer tie rod some room. 6. Spin on the new Outer tie rod, what I did was count how many spins i took to remove it, so thats how much i put it back. since the old and new parts were exactly the same in length. 7. Tighten the lock nut back against the outer tie rod, OEM Spec of torque was 41 ft lbs, but I dont have anything to torque with this kind of nut, just get it tight enough. 8. Install outer tie rod back onto knuckle -Put on castlenut, torque to OEM spec 36 ft lbs -Put on Cotter Pin and bend.  9. Thats it, put back the tire. 10. Mission Completed. Your Car should now look like Boss Status like my 2 Cars below, LOL. Conclusion: Steering Wheel and Feel, tightened up a bit (no loose sounds), so thats what you should notice besides prolly your alignment is F'ED up if you screwed up in that part to count/mark HAHA. I'm not sure if I missed an important step or could've done something better, thats where your feedback comes in. Thats why DIY write ups are tough. Especially when you are trying to get the installation done while taking pics. Just a side note: I've done removal and replace of tie rods just using a pipe wrench in the past, LOL, Ghettofabulous. INNER/OUTER TIE ROD WRITE-UP BY:

This post has been edited by trdproven: Jun 20, 2012 - 12:20 AM -------------------- 94 Celica GT

|Toyota OEM Japan|Toyota Racing Development|Tom's|Competition Clutch|5Zigen|Apexi| |Laille/Beatrush|Magnecor|Denso|Royal Purple|Optima|PIAA|PW JDM|Megan Racing|Nitto| |Work|Greddy|Samco|Project Mu|H&R|Gates|Moog|Rota|Yokohama|Epman|1320|Upgr8 04 Celica GT |Toyota OEM Japan|Toyota Racing Development|Tein|BC Racing|Greddy| |

|

Replies

May 24, 2012 - 3:51 PM May 24, 2012 - 3:51 PM

|

|

|

Enthusiast      Joined Jan 20, '09 From Winnipeg Currently Offline Reputation: 5 (100%) |

Vote for sticky.

-------------------- -Protection mode, For when your amp tries to blow its load. 1995 Toyota Celica GTS - Daily Driver 1999 Chevy Cavalier - Winter Beater 1994 Honda Civic CX Hatchback - Dead My Celica! |

Posts in this topic

trdproven TIE ROD REMOVAL/REPLACE: May 20, 2012 - 7:36 PM

trdproven TIE ROD REMOVAL/REPLACE: May 20, 2012 - 7:36 PM

trdproven its weird, theres really no thread on this forum o... May 23, 2012 - 5:05 PM

trdproven its weird, theres really no thread on this forum o... May 23, 2012 - 5:05 PM

azian_advanced i remember reading up a outer tie rod removal, but... May 24, 2012 - 12:06 AM

azian_advanced i remember reading up a outer tie rod removal, but... May 24, 2012 - 12:06 AM

trdproven yea its hard to get the lock washers flat if its b... May 24, 2012 - 3:40 PM

trdproven yea its hard to get the lock washers flat if its b... May 24, 2012 - 3:40 PM

richee3 QUOTE (jordisonjr @ May 24, 2012 - 3... May 24, 2012 - 4:48 PM

richee3 QUOTE (jordisonjr @ May 24, 2012 - 3... May 24, 2012 - 4:48 PM

S8S8 QUOTE (richee3 @ May 25, 2012 - 7:48... May 25, 2012 - 2:24 AM

S8S8 QUOTE (richee3 @ May 25, 2012 - 7:48... May 25, 2012 - 2:24 AM

Rusty checked the stickies?

it was added the same day as... May 25, 2012 - 3:28 AM

Rusty checked the stickies?

it was added the same day as... May 25, 2012 - 3:28 AM

jordisonjr Woops my bad haha May 25, 2012 - 9:42 AM

jordisonjr Woops my bad haha May 25, 2012 - 9:42 AM

zfjohnson07 dont forget to get your car aligned after you chan... May 25, 2012 - 3:23 PM

zfjohnson07 dont forget to get your car aligned after you chan... May 25, 2012 - 3:23 PM

trdproven Yupp, its in step 12, where it says to count or ma... May 25, 2012 - 4:08 PM

trdproven Yupp, its in step 12, where it says to count or ma... May 25, 2012 - 4:08 PM

BonzaiCelica how do you know if your inner tie rods need replac... Jun 18, 2012 - 12:35 AM

BonzaiCelica how do you know if your inner tie rods need replac... Jun 18, 2012 - 12:35 AM

BonzaiCelica how do you know if your inner tie rods need replac... Jun 18, 2012 - 12:37 AM

BonzaiCelica how do you know if your inner tie rods need replac... Jun 18, 2012 - 12:37 AM

trdproven QUOTE (BonzaiCelica @ Jun 18, 2012 - 3... Jun 19, 2012 - 12:48 AM

trdproven QUOTE (BonzaiCelica @ Jun 18, 2012 - 3... Jun 19, 2012 - 12:48 AM

lagos Thanks for posting this! I'll be using thi... Jun 18, 2012 - 10:05 AM

lagos Thanks for posting this! I'll be using thi... Jun 18, 2012 - 10:05 AM

trdproven yea pretty much exactly the same thing for a corol... Jun 18, 2012 - 6:26 PM

trdproven yea pretty much exactly the same thing for a corol... Jun 18, 2012 - 6:26 PM

azian_advanced the inner tie rods need to be replaced if the inne... Jun 18, 2012 - 10:46 PM

azian_advanced the inner tie rods need to be replaced if the inne... Jun 18, 2012 - 10:46 PM

lagos QUOTE (azian_advanced @ Jun 18, 2012 - 1... Jun 18, 2012 - 10:52 PM

lagos QUOTE (azian_advanced @ Jun 18, 2012 - 1... Jun 18, 2012 - 10:52 PM

trdproven By moving your wheel left to right while jacked up... Jun 19, 2012 - 12:31 AM

trdproven By moving your wheel left to right while jacked up... Jun 19, 2012 - 12:31 AM  |

4 User(s) are reading this topic (4 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: December 4th, 2024 - 2:31 PM |