Apr 5, 2017 - 9:41 AM Apr 5, 2017 - 9:41 AM

|

|

|

Enthusiast Joined Mar 28, '17 From Albany, OR USA Currently Offline Reputation: 0 (0%) |

I spent months researching and looking for rear spats for my convertible. When it comes to body kits, especially mods for the rear of the vehicle, we've all been told that we are simply out of luck or hey, the Curren spats will fit! Have you bought parts from Japan? I have, it's risky, it's expensive and if you don't know exactly what you are looking for you may wind up with something that still does not fit. I decided to wait no longer! My car is going to paint pretty soon and I needed a solution quick. In the course of my life I had never used fiberglass or bondo but it always seemed like it would be fun, I decided to try it. So, I bought a set of TRD replica rear spats and extended them to fit, this is how I did it.

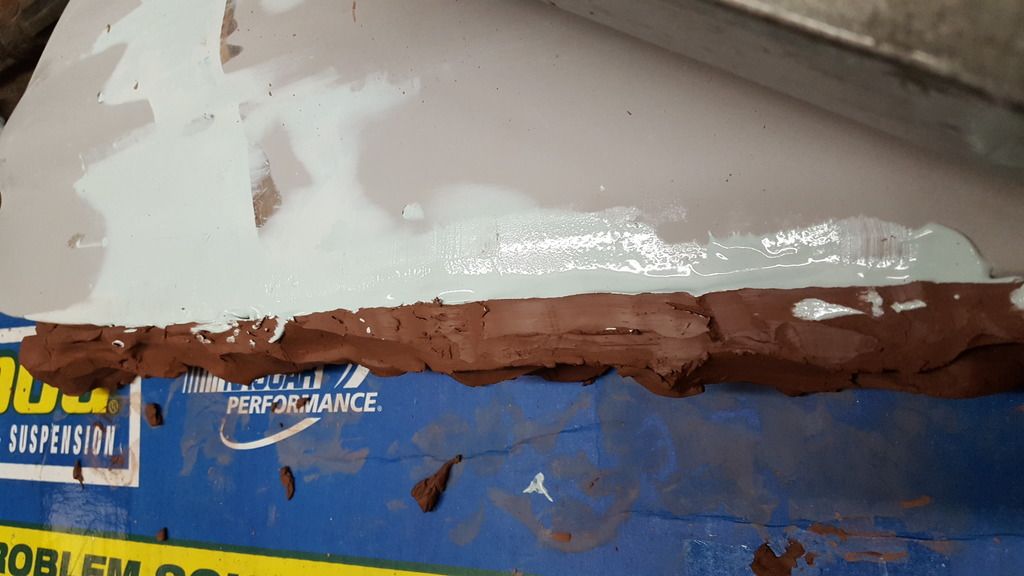

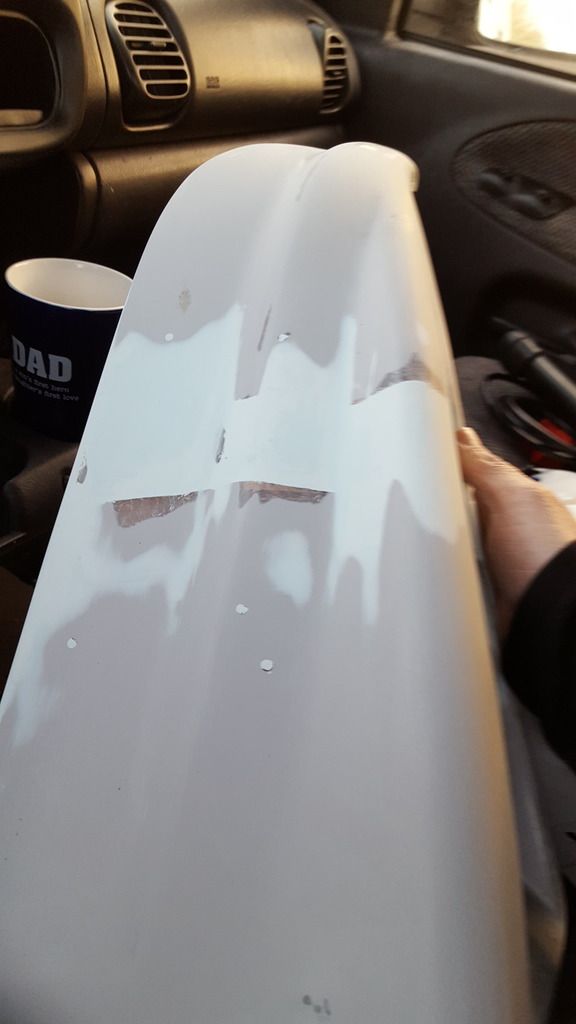

First, I cut them in half (have a little faith). The cut doesn't have to be perfect because the middle is going to be filled in anyway. Then I secured both pieces to the bumper being very careful to line them up perfectly. The rear piece by the tire will secure with 2 factory screws for the mud guard. Make sure you take the mud guard off before you start!!! Slide the front piece around the bend in the bumper until you find the perfect location (no gaps). There is a hole on the bottom, fasten to the bumper using a self tapping screw. It was very helpful having a second person help with the next step. I then used a hot glue gun and secured the two pieces together with some small, flat pieces of wood. Use a long, flat edge to make sure they are not dipping in the middle otherwise you'll have a lot of filling to do. Happened on one of mine.  I know, some of you math nerds are doing the geometry in your head, I know, in the end it will not line up perfectly, your right but close enough. I elected to have the bottom (under the car) be off just a bit. The important thing is to make sure the lines on the face of the spat line up perfectly.  After I had both sides complete I used clay and tin foil to build a base behind the gap. Once complete you will lay about 5 layers of fiberglass overlapping each edge by about 6 inches. Let it cure for about 36 hours.  Remove the mold and clean the surfaces thoroughly.  After drying, fill in the gaps with bondo. I Used a long, flat yet pliable edge to pull the bondo while making contact with the edges of the mold. This will help maintain the shape from end to end.  After the bondo has setup (about 10 min) begin sanding with a long block sander with 120 grit sand paper. This will sand down very quickly and will reveal any low spots that need to be filled. Keep adding and sanding bondo until all the low spots are filled.  I used a clay mold to shape the edge and get it straight. I Pressed a pry-bar into the clay to form the edge then I back filled with bondo then sanded This made the line nice and straight, compare both pictures.    Sand with 320 then 400 then 600 then 800 until smooth. This was my first attempt at fiberglassing, if I can do it you can too. If anybody out there has been following this project I have a quick update, I finished the rear spats, they are painted and installed. I think they turned out pretty good!

This post has been edited by CelicaRelica: May 23, 2017 - 11:57 AM |

Posts in this topic

CelicaRelica Rear TRD Spats Apr 5, 2017 - 9:41 AM

CelicaRelica Rear TRD Spats Apr 5, 2017 - 9:41 AM

njccmd2002 Remove convertible from the header. Youll get mor... Apr 11, 2017 - 9:19 AM

njccmd2002 Remove convertible from the header. Youll get mor... Apr 11, 2017 - 9:19 AM

jordisonjr Nice work! keep this updated as you get them p... Apr 12, 2017 - 8:46 AM

jordisonjr Nice work! keep this updated as you get them p... Apr 12, 2017 - 8:46 AM

CelicaRelica Thanks for the tip! I will definately post fol... Apr 16, 2017 - 4:42 PM

CelicaRelica Thanks for the tip! I will definately post fol... Apr 16, 2017 - 4:42 PM

97Celica QUOTE (CelicaRelica @ Apr 16, 2017 - 4... Feb 25, 2018 - 8:25 PM

97Celica QUOTE (CelicaRelica @ Apr 16, 2017 - 4... Feb 25, 2018 - 8:25 PM

trdproven wish i could see how it looks like one day Mar 3, 2018 - 2:33 AM

trdproven wish i could see how it looks like one day Mar 3, 2018 - 2:33 AM  |

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 22nd, 2024 - 7:54 PM |