|

May 11, 2011 - 8:45 PM May 11, 2011 - 8:45 PM

|

|

Enthusiast    Joined Nov 18, '10 From montreal Currently Offline Reputation: 0 (0%) |

this is not something i suggest for people ,its just one way u can acheive extend your wiring

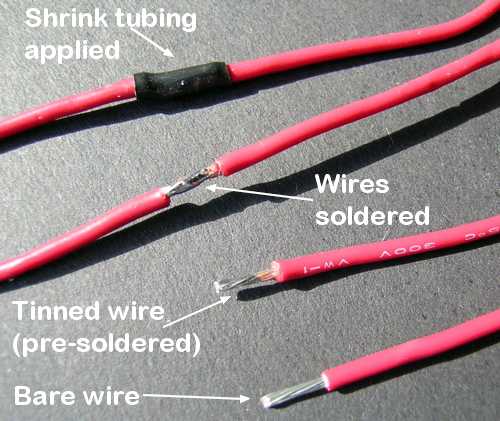

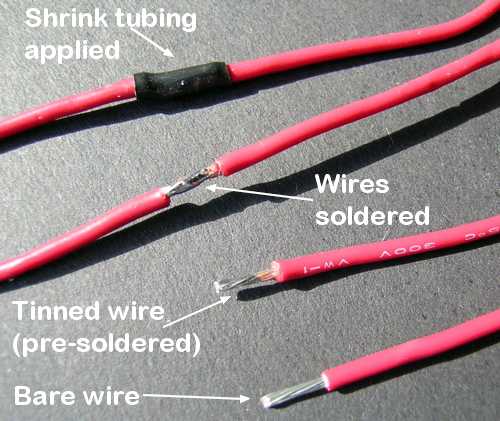

there is a lots of way to extend your wiring when you do your swap. this is one way, the one i did, whitout really being prepared. u can use this and form your own way to do it urself from there first you will need the following tool: ---one good wire splice tool..((sorry im french) (to easely took out the too many wire u will have to splice)) ---one pencil torch or a bic lighter ---cutter ---shrink tube to cover and securise each connection (dont use tape) ---welding pencil --- weldind metal ---use scott towell to clean your welding pencil and keep the same u will need some patience also how to weld: first , u will need to learn how to weld, its pretty easy thecnique for welding=when you have two wire u can connect them by twisting it or separate each wire inside from each other in form of star (what i did) and just reach them together and twist it around all wire together, its not important if its not hold tight at this point, your weld will tight it off whaen u weld its 3 point weld for those wire, one touch (1 or 2 sec) on top and one touch on each side of the wire whit your pencil weld and the wire weld stuff, if the stuff dont weld nicely on the wire, you can slide your pencil a little bit, dont put too much stuff cause ur wire gonna be too big and the resistance not appropriate and u will have trouble loom it back inside the hole of the firewall after cutting any wire be sure to place your rubber piece around the two side of wire...or you will have to cut it back for nothing, thats frustrating after joined the wire together and weld it, u just slide the rubber and heat it up, ( dont use the red flamme of the lighter or torch, u dont want to burn it, you want to heat it so that can shrink whitout burning, use the blue of your lighter or place ur rubber very near of your lighter) i did extend my wiring whit my engine and everything installed in the car first you start by unloom your wiring behin your charge cooler, until the end plug to cpu,  from there you will have to unloom all your old wiring from 5sfe get some mesure (i use something like 28 to 30 inch) 28 is minimum, and then cut all my old wire from old harness at the same lenght, after you will want to cut the tip of each side to prepared to be connected (unloom the tip)try to use the same color for your extention.but i ended up missing some wire for match color...i used other color wire or u can buy the missing one to match color. one good step to start the job is to seek where the jonction is, some wire alone , split in 3 at certain time, so extend the one wire not the 3 wire ... so, you will have to cut it to different place, check it and figure it out, the best way to start the job is to cut the wire (i think 2 or 3 ) that are alone from the harness red blue wire i think not sure) these wire are separate in the harness from all junction , so its a good way to start, cut those one, and extend it and put it a part ,on the side, each time you will cut and extend one wire at a time ,and put it on the side, whit the other wire ,that are already extend . so you dont get confuse, i suggest to cut one wire at a time and extend it and finish it and put it on the side before cutting another wire but, my friend who show me this have started the job by cutting a couple wire and identyfy the one whit same color, i think its better to do mit one at a time, abunch of wire will be in the way, so you maybe want to put those on the wiper, put the whipper up and put ur extra extended wire there, at this point some wire on the wiper, some on the right side are extend and in the middle still the wiring that is not extend the wire in the picture is the one that is good to start whit  just continue the process until its done, be sure to secure each connection when melting the rubber on it, it need to secure humidity, think of that the rest is looming back the harness together, im sure at this point you have your own idea how to do it lol  dont use that torch, lighter is better or pencil torch

This post has been edited by Needles: May 12, 2011 - 11:28 AM |

May 12, 2011 - 6:12 AM May 12, 2011 - 6:12 AM

|

|

|

Enthusiast   Joined Feb 28, '11 Currently Offline Reputation: 5 (100%) |

i dont recommend solder or wire welding, over time these can break and cause a big problem for u.

|

May 12, 2011 - 6:33 AM May 12, 2011 - 6:33 AM

|

|

|

Enthusiast   Joined Jan 3, '06 From The Netherlands Currently Offline Reputation: 6 (100%) |

What do you recommend then? Since soldering is the best and safest way to extend the wire harness!

-------------------- JDM ST205

|

May 12, 2011 - 7:50 AM May 12, 2011 - 7:50 AM

|

|

|

Enthusiast   Joined Feb 28, '11 Currently Offline Reputation: 5 (100%) |

What do you recommend then? Since soldering is the best and safest way to extend the wire harness! soldering is most def not the best way. It breaks over time and can short out easy. If anything let the a professional do it. There is more to just soldering than soldering, u just can't solder something and put tape over, u are asking for a problem. And big one. It can lead to a short. Or even wrost short out your whole ecu. If you are going to solder I would heat shrink over it. And if soldering is not done right it can mess up your resistance in the wire.....and also a short in the wire could cost you your car which it could burn down. Like I said. It is better for a professional to do it or even somebody that knows what they are doing... if u want to risk and few bucks to do it the cheap way... yes this is a great way to do it, but not one I recommend and if u ask a professional of many years, I'm sure he will say the same thing. This isn't. Hooking up some radio. Or something cheap it a ecu that is hard to come by all I'm saying is if u are going to solder do it the right way, not solder and tape.....and there are many other ways to extend a wire.. if you have the time and money I say re run the whole wire and cut it to where you need it.and another thing is that soldering a wire. Just think what happens when u go to bend the wire solder isn't made to flex, so what's going to happen is its going to break.... professional is the best way to go

This post has been edited by brenton1919: May 12, 2011 - 8:05 AM |

May 12, 2011 - 11:25 AM May 12, 2011 - 11:25 AM

|

|

Enthusiast    Joined Nov 18, '10 From montreal Currently Offline Reputation: 0 (0%) |

What do you recommend then? Since soldering is the best and safest way to extend the wire harness! soldering is most def not the best way. It breaks over time and can short out easy. If anything let the a professional do it. There is more to just soldering than soldering, u just can't solder something and put tape over, u are asking for a problem. And big one. It can lead to a short. Or even wrost short out your whole ecu. If you are going to solder I would heat shrink over it. And if soldering is not done right it can mess up your resistance in the wire.....and also a short in the wire could cost you your car which it could burn down. Like I said. It is better for a professional to do it or even somebody that knows what they are doing... if u want to risk and few bucks to do it the cheap way... yes this is a great way to do it, but not one I recommend and if u ask a professional of many years, I'm sure he will say the same thing. This isn't. Hooking up some radio. Or something cheap it a ecu that is hard to come by all I'm saying is if u are going to solder do it the right way, not solder and tape.....and there are many other ways to extend a wire.. if you have the time and money I say re run the whole wire and cut it to where you need it.and another thing is that soldering a wire. Just think what happens when u go to bend the wire solder isn't made to flex, so what's going to happen is its going to break.... professional is the best way to gothat what i say, heat shrink, did u read carrefylly, i say dont use tape....and how do you think proffesionnal do lol ?? they sold and shrink tube on it. u will need tape only at the end to loom it back all the wiring together This post has been edited by Needles: May 12, 2011 - 11:30 AM |

May 12, 2011 - 1:36 PM May 12, 2011 - 1:36 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

Soldering is perfectly fine and much better than normal crimping. If your solder breaks, than you are not soldering correctly. My harness has been soldered and running perfectly for well over six years now. And he clearly says and shows to use heat shrink tubing. Obviously electrical tape will fall off over time and cause problems, but no one here is recommending that.

But the bottom line that I agree with is that if you have no prior wiring experience, its best to pay someone who knows what they are doing for any kind of harness work. But its also good to have a write up like this for those who are interested in learning! This post has been edited by lagos: May 12, 2011 - 1:41 PM -------------------- 15PSI - 30MPG - Megasquirt Tuned

|

May 12, 2011 - 4:44 PM May 12, 2011 - 4:44 PM

|

|

|

Enthusiast      Joined May 29, '09 From Gainesville, FL Currently Offline Reputation: 17 (100%) |

What do you recommend then? Since soldering is the best and safest way to extend the wire harness! soldering is most def not the best way. It breaks over time and can short out easy. If anything let the a professional do it. There is more to just soldering than soldering, u just can't solder something and put tape over, u are asking for a problem. And big one. It can lead to a short. Or even wrost short out your whole ecu. If you are going to solder I would heat shrink over it. And if soldering is not done right it can mess up your resistance in the wire.....and also a short in the wire could cost you your car which it could burn down. Like I said. It is better for a professional to do it or even somebody that knows what they are doing... if u want to risk and few bucks to do it the cheap way... yes this is a great way to do it, but not one I recommend and if u ask a professional of many years, I'm sure he will say the same thing. This isn't. Hooking up some radio. Or something cheap it a ecu that is hard to come by all I'm saying is if u are going to solder do it the right way, not solder and tape.....and there are many other ways to extend a wire.. if you have the time and money I say re run the whole wire and cut it to where you need it.and another thing is that soldering a wire. Just think what happens when u go to bend the wire solder isn't made to flex, so what's going to happen is its going to break.... professional is the best way to goA good solder joint will not break under min stress. Its called tinning the wires. You simply heat up the wire with a little solder, then apply solder to the whole tip until it would appear it has wrapped around every piece of the wire strand. Do this for both side, then solder them together after you've completed the tinning. Not only does this make a secure connection, it also makes it simplier to combine the two in a hard spot. Not really rocket science, just simple soldering. You wanna get really extreme if you are paranoid and don't trust your work...simple get the wire metal crimps, crimp'em down, and apply solder....overkill, but yea.. This post has been edited by rave2n: May 12, 2011 - 4:45 PM |

May 12, 2011 - 10:14 PM May 12, 2011 - 10:14 PM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

nah the best way to solder is to get the wires together and use a strand of wire to hold them together and then solder over that strand both wires.

just like tying shoelaces. thats what i did on my swap.   that belly u see there is the wire holding the wires together and then soldered over, yeah its overkill but it will never break -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

May 12, 2011 - 10:17 PM May 12, 2011 - 10:17 PM

|

|

|

Enthusiast      Joined May 29, '09 From Gainesville, FL Currently Offline Reputation: 17 (100%) |

Sounds neat, agreed on overkill =P

This post has been edited by rave2n: May 12, 2011 - 10:18 PM |

May 12, 2011 - 10:39 PM May 12, 2011 - 10:39 PM

|

|

Enthusiast    Joined Nov 18, '10 From montreal Currently Offline Reputation: 0 (0%) |

Sounds neat, agreed on overkill =P  this shrink tube should be larger , to be sure its cover and secure no need overkill soldering, if your wire gonn a broke, it gonna broke at another place than where you made your soldering one simple sold, and you cannot broke the wire whit pulling hard whit your two arm This post has been edited by Needles: May 12, 2011 - 10:43 PM |

May 13, 2011 - 4:40 AM May 13, 2011 - 4:40 AM

|

|

Enthusiast      Joined Feb 11, '08 From Auckland, New Zealand Currently Offline Reputation: 0 (0%) |

I interlock the strands of wire then give it a little twist to solder.

-------------------- Mike W

1996 Toyota Celica ST205 GT-FOUR GT2860RS turbine, TiAL mvr44, JE 86.5φ piston, Clutchmasters FX400, APEX P-FC 269awhp / 273ft-lbs |

May 13, 2011 - 4:45 AM May 13, 2011 - 4:45 AM

|

|

Enthusiast      Joined Feb 11, '08 From Auckland, New Zealand Currently Offline Reputation: 0 (0%) |

if you do rave2n's way you gotta be extra careful of impurities from an unclean soldering iron, or wire insulation, or melted copper etc

-------------------- Mike W

1996 Toyota Celica ST205 GT-FOUR GT2860RS turbine, TiAL mvr44, JE 86.5φ piston, Clutchmasters FX400, APEX P-FC 269awhp / 273ft-lbs |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 27th, 2024 - 6:07 AM |