|

Jul 22, 2011 - 7:39 AM Jul 22, 2011 - 7:39 AM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

Variable Length Intake Manifold (with info regarding ACIS and turbo) Actually the ST162 1st Gen 3S-GE had TVIS, did you mean to write ST215 intake manifold by chance? I guess would be up to personal preference which either intake manifold you use... but maybe not one of the TVIS manifolds if you mean what i said then no, st162 inlet manifold is an alternative to the centre feed inlet manifold of the st185, its side feed and seems to be an improvement, the tvis heads have huge inlet ports on them so you need a manifold that will match that, these large ports are undesirable really, the rev 2 3s-gte has very large port openings which taper down very aggrsivly to the valves and its not good for flow. Hence why the small port rev 2 3s-ge head is a better starting point when doing a ground up engine build. The exhaust manifold stud patterns are the same between the na and turbo versions of each revision, they however change on each revision, so rev 2 3s-gte manifold fits a rev 2 3s-ge, and so on, this isnt true however of the 4th gen 4s-gte, which shares its stud pattern with the rev 3 3s-gte, whilst the 4th and 5th gen 3s-ge's both share a unique manifol stud pattern for both intake and exhaust. as for vvti/vtec they are different things, the vtec is two seperate sets of cam lobes on one cam, and it switched between them at a set rpm, vvti alters the phasing of the cam, so the cam timing relative to the crankshaft, and it does this constantly changing depending on throttle input and rpm. vvti is a power gain, it allows you to run a more aggresive cam for better top end, whilst being able to vary the cam phasing means you can retain or gain lower to mid range power that would have been otherwise lost from the more aggresive cam. In a forced induction engine it allows you to tune the cam timing for different rpms so you can help build boost sooner and extend the power band of the engine. In the past vvti was seen as an added complication but its so prevelant among cars now that its not a problem anymore and is a definite gain. the vvti 3s-ge heads are a different casting to previous 3s heads, both the redtop and blacktop are the same with some minor differences in water outlets, they are however a unique casting in relation to the previous 3s engines, they have a narrower valve angle and the head is in general a lot narrower than previous 3s variants, and as i've mentioned before they have a unique stud pattern. Block wise they are the same as previous 3s engines, apart from they have an extra oil feed to the head for the vvti, i'm not sure if that could be added to a pre beams block, either way unless your stroking and need a 5s block it doesnt matter as the beams blocks are reputed to be the strongest castings of 3s engines to date, and the same as the motorsport blocks, altezza blocks have been used in gt-fours as a basis for rebuilds due to this, but using rev 3 head and sump. The blacktop has apparently the highest output oil pump due to the two vvti controllers which are oil pressure driven, but in order to use that oil pump on a non beams engine you will need a redtop sump, as both the sump and the oilpump have a recess for the crank angle sensor. Due to the head being narrower the vvti heads also need a different timing belt. you can mix and match the heads as much as you like but obviously only the beams blocks have the vvti feed, and you will need compatible manifolds for whichever head you use, but you can fit normal cam gears instead and lose the vvti, you'd probably still gain power thanks to the newer head casting and inlet manifold etc, the valves are larger as standard on the vvti head as well as some nice features such as sodium filled exhaust valves on the redtop and titanium inlet valves on the blacktop which are 1.5mm larger than a 3s-gte. If you wanted to fit a blacktop into a celica though you need to swap the manifolds/sump/oilpickup and depending what you do with the water ways you may need to change the headgasket for a redtop. The exhaust side vvti controller will clash with the engine mount on that side but in all honesty it doesnt gain you much so fitting a normal cam gear instead would be a simple fix. Redtop obviously doesnt have that issue. If you were building the ultimate 3s-gte you'd start with a redtop or blacktop/redtop hybrid and retain inlet vvti. Hks back in 99 used a redtop beams engine built for turbo to set the fwd drag record in a celica, although at the time they chose not to use vvti, understandable in a drag car as your only interested in a narrow power band. For any full on 3s-gte engine build that is going to require headwork, ie larger valves and more aggressive cams, it is worth thinking about instead of spending the money on the head, spending it on a redtop as the starting point due to its already 1m oversized valves, and more aggressive cams, and it will come with the bonus of inlet vvti, and the strongest block casting, and as an added bonus it already has a crank angle sensor so when you go for an aftermarket ecu, the engine already has the sensors needed in place to run it. the only downside of using the beams for a turbo application is the need to fabricate an exhaust manifold, but for many that isnt a problem. |

Jul 22, 2011 - 8:34 AM Jul 22, 2011 - 8:34 AM

|

|

Enthusiast      Joined Feb 11, '08 From Auckland, New Zealand Currently Offline Reputation: 0 (0%) |

the main thing with the blacktop is figuring out whether it's going to sit in an altezza or a celica, as to what parts you choose, as you need the blacktop sump for an upright rwd setup, any other sump for a tilted traverse engine mounting

the intake manifold and throttle body may end up in a wrong position but thats okay, interchangable -------------------- Mike W

1996 Toyota Celica ST205 GT-FOUR GT2860RS turbine, TiAL mvr44, JE 86.5φ piston, Clutchmasters FX400, APEX P-FC 269awhp / 273ft-lbs |

Jul 23, 2011 - 1:45 AM Jul 23, 2011 - 1:45 AM

|

|

|

Enthusiast     Joined Jun 25, '06 From Box Elder, South Dakota Currently Offline Reputation: 2 (100%) |

Found some more info whilst parusing the net. Seems that its true that you can use 3rd-5th gen 3sgte rods and crankshaft with the beams blacktop. But you cannot use the 3rd gen pistons due to a difference in valve reliefs. Actually the valve relifs in the blacktop beams are differnt because of the angle of at which the valves sit.

Beams on the left, 3sgte on the right. Also you can just look at a diagram of the spacing of the 3sgte and (beams) 3sge and see a noticable differnce in spacing btwn the cams alone.  Also cam across some good info in that the bucket sizes and actual valve size are considerebly larger than on the 3sgte engines. Oil pump is obviously larger due to the increases need for oil in the blacktop engine. Ill list the valve and bucket sizes below. Buckets/lifters = 31mm (auto) Buckets/lifters = 33mm (manual) Intake Valve Diameter: 34.5mm Exhaust Valve Diameter: 29.5mm Another interesting thing of note that i hope someone can clarify, is that i hear due to manifold pressure VVTI works up until +0% manifold pressure...In other words, in a turbocharged application, as along as you werent on boost you would be driving around with VVTI engaged up until manifold pressure exceeds +0% If that is true, then that would be an awesome "stop gap" until you come up on boost, in which case the engine should behave much like any other turbo 3sgte. So assuming all of this provided is 100% fact, i think its safe to say, there is a very good reason to turbocharge a 3sge........atleast a beams one. Larger oil pump, thicker more improved upon block, VVTI until you come up on positive manifold pressure, larger valves, a better diesigned head (something of note i found whilst searching for info), and the ability to use any other transmission that would normally bolt onto a 3sg block....hmm i see alot of potential there. Now this leaves me wondering if anyone has ever put one in a 6th gen celica, turbo or not? -------------------- (\__/)

(='.'=) This is bunny. Copy and paste bunny into your (")_(") signature to help him gain world domination. |

Jul 23, 2011 - 1:53 AM Jul 23, 2011 - 1:53 AM

|

|

|

Enthusiast     Joined Jun 25, '06 From Box Elder, South Dakota Currently Offline Reputation: 2 (100%) |

EDIT: have also read that an easier way to overcome the problem with the exhaust side controller, is to either get rid of your cam cover gasket, and or use a 3rd gen one with a recess cut out for the controller...anyone got any verification on this? Heard it makes it possible to install "that sides" mount.... the main thing with the blacktop is figuring out whether it's going to sit in an altezza or a celica, as to what parts you choose, as you need the blacktop sump for an upright rwd setup, any other sump for a tilted traverse engine mounting the intake manifold and throttle body may end up in a wrong position but thats okay, interchangable I agree with you on the sump issue. But aftet trying to visually compare the 3sgte and beams oil pans (upper and lower) it looks as if it should have no problem clearing our subframes, as the 3sgte upper pan looks larger to begin with, and the lower 3sge seems to be larger. If anything using a lower 3sgte oil pan and pickup with the blacktops upper, just might do the trick. This post has been edited by 3WayStunna: Jul 23, 2011 - 2:02 AM -------------------- (\__/)

(='.'=) This is bunny. Copy and paste bunny into your (")_(") signature to help him gain world domination. |

Jul 23, 2011 - 3:31 AM Jul 23, 2011 - 3:31 AM

|

|

Moderator      Joined Nov 5, '07 From New Zealand Currently Offline Reputation: 3 (100%) |

however with the gen 2 3sge, may require you to convert to shim under bucket or shim less, depending on your goals or usage.

ahh thats what it was, the head differences was a different cast. But from what I read, there isn't much difference in strength between the blacktop and ST205 blocks according to glenn booth, which may explain why it was harder to find details of people who where using that block in their ST205. If you really did want to retain the vvti and couldn't for some reason use the internal feed from the block up to the vvti solenoid, you could make up an external line up to the head/vvti solenoid like the people who build RB30's that want to retain the N-VCT . Also from what I've worked out the cranks are the same between 3rdgen & 4th gen 3sge/gte, redtop and blacktop. The 3sge/3sgte cranks are factory forged, while 5s/3sfe cranks are cast. And the redtop BEAMS rods are the same as the 4th gen 3sgte. I wouldn't say 'considerebly larger' ours being Valve diameter In: 33.5mm Valve diameter Ex: 29.0mm but being made out of titanium is a nice touch. I came across the same info as you have 3WayStunna, while I was looking for the valve angle difference the beams has, but could not find it. well apart from the difficulty reasons of installing. the next trouble would come from wiring it all in. -------------------- |

Jul 23, 2011 - 5:43 AM Jul 23, 2011 - 5:43 AM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

the st205 blocks were revised at some point due to wall thickness, later blocks will be similar to the beams blocks, seen plenty of early blocks split a cylinder wall as soon as the boost is increased.

for the blacktop exhaust controller simply removing the cam cover wont work, even in the st182 the clearence is minimal, pretty sure its impossible in a st20x without doing something with the engine mount, or dropping the exhaust vvti, i never tried it myself, i just had a look and thought no way.. vvti on the beams has nothing to do with manifold pressure, the vvti controller is driven by the ecu alone, and the beams dont even have a map sensor to read manifold pressure, it will alter the valve angle to whatever you set in the ecu tables. I believe although i've never seen it done myself you can actually fit a beams head on a 3s-gte block and it'll work (not sure how true that is), but your compression ratio will be over 12:1 or something like that, the beams has a smaller combustion chamber than previous 3s engines. you'd really need a programmable ecu for a boosted beams, if you were hybriding an earlier 3s-ge using 3s-gte parts you can use a 3s-gte ecu, but for a beams turbo your really going to need to either run very little boost something like 5psi at most or go aftermarket. Anyway redtop beams wiring is sooo easy, much easier to deal with than older 3s engines, blacktop beams however is a nightmare lol. I dont think you can mix and match sump parts, i would think you need to use a complete sump be it in two parts or one, from the same engine along with the appropriate oil pump as they will match up. I can check some of these things if you guys have questions as I have at the moment a rev 2 3s-gte, and a beams blacktop that i've converted to redtop in the garage at the moment, i dont have the blacktop sump or intake manifold anymore though, and i've got a rev 3 3s-gte in my st205 to compare. I also keep a bare blacktop head for measuring purposes. This post has been edited by Edophus: Jul 23, 2011 - 6:43 AM |

Jul 23, 2011 - 5:59 AM Jul 23, 2011 - 5:59 AM

|

|

Enthusiast      Joined Feb 11, '08 From Auckland, New Zealand Currently Offline Reputation: 0 (0%) |

the st205 blocks were revised at some point due to wall thickness, later blocks will be similar to the beams blocks, seen plenty of early blocks split a cylinder wall as soon as the boost is increased. for the blacktop exhaust controller simply removing the cam cover wont work, even in the st182 the clearence is minimal, pretty sure its impossible in a st20x without doing something with the engine mount, or dropping the exhaust vvti, i never tried it myself, i just had a look and thought no way.. vvti on the beams has nothing to do with manifold pressure, the vvti controller is driven by the ecu alone, and the beams dont even have a map sensor to read manifold pressure, it will alter the valve angle to whatever you set in the ecu tables. I believe although i've never seen it done myself you can actually fit a beams head on a 3s-gte block and it'll work (not sure how true that is), but your compression ratio will be over 12:1 or something like that, the beams has a smaller combustion chamber than previous 3s engines. you'd really need a programmable ecu for a boosted beams, if you were hybriding an earlier 3s-ge using 3s-gte parts you can use a 3s-gte ecu, but for a beams turbo your really going to need to either run very little boost something like 5psi at most or go aftermarket. Anyway redtop beams wiring is sooo easy, much easier to deal with than older 3s engines, blacktop beams however is a nightmare lol. I dont think you can mix and match sump parts, i would think you need to use a complete sump be it in two parts or one, from the same engine along with the appropriate oil pump as they will match up. I can check some of these things if you guys have questions as I have at the moment a rev 2 3s-gte, and a beams blacktop that i've converted to redtop in the garage at the moment, i dont have the blacktop sump or intake manifold anymore though, and i've got a rev 3 3s-gte in my st205 to compare. boost pressure could be a good way of continuous vvti triggering provided my understanding is correct that it's a one shot operation, small cam to big cam as opposed to a true continuously variable system that gradually increases profile sump parts fit fine with some extra drilling and tapping... -------------------- Mike W

1996 Toyota Celica ST205 GT-FOUR GT2860RS turbine, TiAL mvr44, JE 86.5φ piston, Clutchmasters FX400, APEX P-FC 269awhp / 273ft-lbs |

Jul 23, 2011 - 6:20 AM Jul 23, 2011 - 6:20 AM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

boost pressure could be a good way of continuous vvti triggering provided my understanding is correct that it's a one shot operation, small cam to big cam as opposed to a true continuously variable system that gradually increases profile sump parts fit fine with some extra drilling and tapping... yeah the sump parts can be modified to fit for sure with some metal work, i have seen a rev 3 sump modified to fit a rev 5 oil pump, wasnt pretty though lol but worked and probably better than using a blacktop sump because the oilpickup will be in the right place for transverse, personally i would just use the right sump for whatever i was doing though, so if using a beams oil pump use a redtop sump, its already the perfect fit for a 6th gen, and if using a 3s-gte oil pump use a rev 3 3s-gte sump. the vvti on the beams isnt a one shot like the older vvt on the 4age engines, the ecu adjusts the cam phasing from 0rpm to the limiter depending on various things, i'm not sure what they all are cause you cant access the ecu, but from memory when i used the power-fc and the from the other ecu's i've looked at its i think by rpm and load, you just set a value which is the advance or retard of the cam relative to the crankshaft, so you just set it and the ecu controls the solenoid that feeds the oil pressure to the cam controller, so its whatever you set in the ecu, and unnaffected by things like boost pressure. |

Jul 23, 2011 - 7:11 AM Jul 23, 2011 - 7:11 AM

|

|

Enthusiast      Joined Feb 11, '08 From Auckland, New Zealand Currently Offline Reputation: 0 (0%) |

then what is it you hear "kicking in" on 4age blacktops? when they cross over the 4500ish mark

-------------------- Mike W

1996 Toyota Celica ST205 GT-FOUR GT2860RS turbine, TiAL mvr44, JE 86.5φ piston, Clutchmasters FX400, APEX P-FC 269awhp / 273ft-lbs |

Jul 23, 2011 - 7:37 AM Jul 23, 2011 - 7:37 AM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

then what is it you hear "kicking in" on 4age blacktops? when they cross over the 4500ish mark probably vvt kicking in, i'm not clued up on the 4a-ge engines to be honest but unless they changed to vvti for the blacktop after the silvertop 4a-ge then its just vvt, not vvti, which essentialy is a system that is switched on at a given rpm, so in the 4a-ge engines it does kick in, its not the same as the constantly variable vvti of the blacktop/redtop beams and the zz series engines. |

Jul 23, 2011 - 12:21 PM Jul 23, 2011 - 12:21 PM

|

|

|

Enthusiast     Joined Jan 19, '11 From Paraguay, Winchestertonfieldville Currently Offline Reputation: 1 (100%) |

all this talk of vvti is starting to turn me on, could a redtop be put on a 3sgte if you changed the oil pump/sump thingamabob and EMS would that be a great for quick spoolup on a big turbo

-------------------- |

Jul 23, 2011 - 2:37 PM Jul 23, 2011 - 2:37 PM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

all this talk of vvti is starting to turn me on, could a redtop be put on a 3sgte if you changed the oil pump/sump thingamabob and EMS would that be a great for quick spoolup on a big turbo its best to start with a greytop beams tbh as they are the cheapest variant, and identical for this purpose to a redtop, use the whole engine and insert forged pistons and rods, get an exhaust manifold fabricated for turbo, bigger injectors, and tune it with an aftermarket ecu and you'll have a great turbo engine. here is a nice example, keeping in mind it was due more mapping, had a 2.5 inch downpipe and a stock mr2 turbo exhaust, it shows the beams has a lot of potential in a turbocharged application. http://www.mr2.com/forums/beams-owners-gro...urbo-beams.html This post has been edited by Edophus: Jul 23, 2011 - 2:58 PM |

Jul 24, 2011 - 1:08 AM Jul 24, 2011 - 1:08 AM

|

|

|

Enthusiast     Joined Jun 25, '06 From Box Elder, South Dakota Currently Offline Reputation: 2 (100%) |

Are the injectors on the redtop beams top feed/side feed, high/low impedence?

Any figures on cam duration or lift for either the red/gray/blacktop? Seems i cant find anything with this... And from what i can tell, the spacing btwn the cams on the redtop look similar to the 3sgte (3rd gen) so im assuming the angle of the valves are the same, and thus you can use 3sgte pistons with no problems?? EDIT: Redtop uses top feed/low impedence (peak and hold type) injectors. This post has been edited by 3WayStunna: Jul 24, 2011 - 1:56 AM -------------------- (\__/)

(='.'=) This is bunny. Copy and paste bunny into your (")_(") signature to help him gain world domination. |

Jul 24, 2011 - 3:54 AM Jul 24, 2011 - 3:54 AM

|

|

Moderator      Joined Nov 5, '07 From New Zealand Currently Offline Reputation: 3 (100%) |

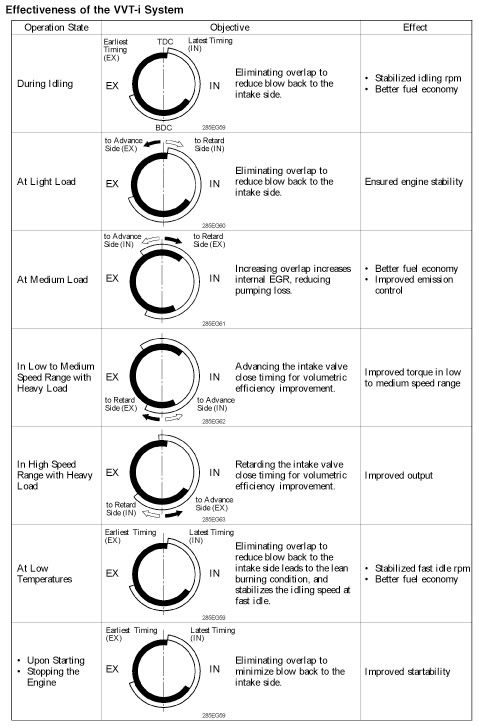

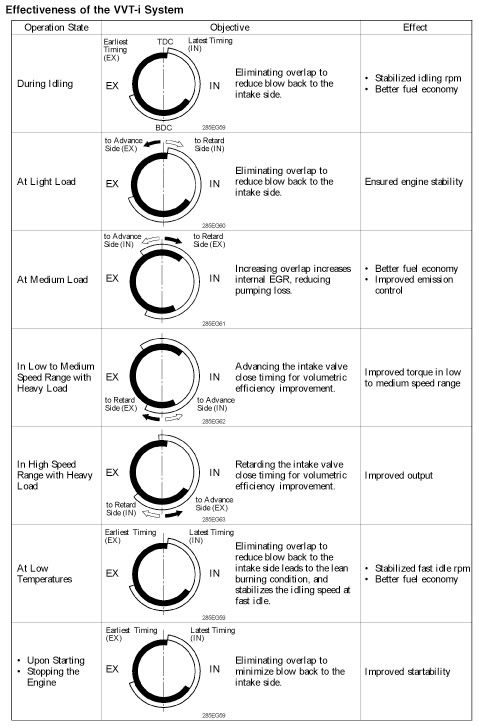

info regarding ST205 thick or thin block

Would like to see more truth/evidence in using blacktop blocks with 3rd gen 3sgte heads, as I looked back at your blacktop head you posted ages ago and compared it to a 3rd gen 3sgte block, and almost looks like there was a bit of difference between them (disregarding the vvti line), but could have been the angle etc of the pictures too. Actually from what I've read & understand the Blacktop 3S-GE's vvti operates up to 6000rpm, which does make sense. I have a diagram, that shows the different points of vvti usage in the dual vvti.  We do have these specs in our 3S-GE/BEAMS thread 4 Gen BEAMS Redtop 3S-GE IN: 256deg, 10.5mm lift EX: 244deg, 9.2mm lift Thats the advertised duration, which doesn't mean too much. you need the accurate way of camshaft measurement which is the '###degrees @ .050" '. I'm sure you have the specs edophus? No the BEAMS has a narrower valve angle,which I cant seem to find, but ours is 44.5° -------------------- |

Jul 24, 2011 - 5:52 AM Jul 24, 2011 - 5:52 AM

|

|

|

Enthusiast     Joined Jun 25, '06 From Box Elder, South Dakota Currently Offline Reputation: 2 (100%) |

WOW rusty that is some awesome info you posted up there....btw i wasnt too much aware of a beams thread, might take a read into it all....I dont know, but turbocharging a beams 3sge seems more and more worthwhile the more its discussed about.

Anywho i cam across a thread on the beams forums that had the valve angles for the blacktop but not the redtop...wish i wouldve saved that info.. QUOTE Would like to see more truth/evidence in using blacktop blocks with 3rd gen 3sgte heads, as I looked back at your blacktop head you posted ages ago and compared it to a 3rd gen 3sgte block, and almost looks like there was a bit of difference between them (disregarding the vvti line), but could have been the angle etc of the pictures too. Yea that is a good question because the blacktop blocks have seperate oil passages just for the VVTI...be interesting to see how you could just swap a 3rd gen head on their...maybe they both have the same passages, or there is some way to block them?? This post has been edited by 3WayStunna: Jul 24, 2011 - 6:09 AM -------------------- (\__/)

(='.'=) This is bunny. Copy and paste bunny into your (")_(") signature to help him gain world domination. |

Jul 24, 2011 - 6:14 AM Jul 24, 2011 - 6:14 AM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

info regarding ST205 thick or thin block Would like to see more truth/evidence in using blacktop blocks with 3rd gen 3sgte heads, as I looked back at your blacktop head you posted ages ago and compared it to a 3rd gen 3sgte block, and almost looks like there was a bit of difference between them (disregarding the vvti line), but could have been the angle etc of the pictures too. Actually from what I've read & understand the Blacktop 3S-GE's vvti operates up to 6000rpm, which does make sense. I have a diagram, that shows the different points of vvti usage in the dual vvti.  We do have these specs in our 3S-GE/BEAMS thread 4 Gen BEAMS Redtop 3S-GE IN: 256deg, 10.5mm lift EX: 244deg, 9.2mm lift Thats the advertised duration, which doesn't mean too much. you need the accurate way of camshaft measurement which is the '###degrees @ .050" '. I'm sure you have the specs edophus? No the BEAMS has a narrower valve angle,which I cant seem to find, but ours is 44.5° i'm pretty sure one guy who has used a blacktop block with rev 3 3s-gte head is on this forum but i cant remember his name lol. I dont have those cam specs, the only person i can think of who might have that is g.booth. Also i'm sure the beams engines use high impedence injectors, same as the zz engines. I think its worth noting that it seems to be a waste of money going for expensive aftermarket cambelts or head gaskets with the beams, the oem ones are very good items, both the one i linked above and the ~300bhp na engines g.booth builds use oem beams headgaskets and belts. This post has been edited by Edophus: Jul 25, 2011 - 5:42 AM |

Jul 26, 2011 - 7:04 AM Jul 26, 2011 - 7:04 AM

|

|

|

Enthusiast   Joined Dec 30, '10 From amarillo texas Currently Offline Reputation: 6 (100%) |

we really need to stop with this thread all its making me do is wana turbo a redtop. so i was thinkin..... a little work to the head, new valve train, good set of pistons and rods, drop the compression to about 9:1, with like a t28 or t30, keep the stock intake cam and run the gen3 NA intake cam on the exhaust should give you a 256/252 setup, and of course all the supporting mods. i do dare say you would have one MEAN little beams. yo 3way you need to hurry and leave the ROK and get back to this rock so we can make this happen. lets be the first ones to get a 6GC in a superstreet or something lol!!!!

|

Jul 26, 2011 - 9:01 AM Jul 26, 2011 - 9:01 AM

|

|

|

Enthusiast     Joined Jun 25, '06 From Box Elder, South Dakota Currently Offline Reputation: 2 (100%) |

Dude im there....already speccing out my 3sge build. I mean seriously i agree, the redtop seems to be the way to go in terms with turbocharging a 3sge.

-------------------- (\__/)

(='.'=) This is bunny. Copy and paste bunny into your (")_(") signature to help him gain world domination. |

Jul 28, 2011 - 2:55 AM Jul 28, 2011 - 2:55 AM

|

|

Moderator      Joined Nov 5, '07 From New Zealand Currently Offline Reputation: 3 (100%) |

found some info on an altezza forum

QUOTE Other notes: Retard Timing about 1 degree per PSI of boost. 2JZGTE Pistons will fit with slight machining to the piston skirt for oil squirters, factory 3SGE rings will fit the 2JZ Pistons. 3SGTE rods fit the 2JZ pistons with machining work. 3SGTE rods will bolt up to 3SGE pistons and 3SGE crank, they are stronger than factory 3SGE rods. Compression with 2JZGTE pistons and stock headgasket is 9.6:1 which is perfect for good response SAAB boost. Compression with 3SGTE 3rd Gen pistons is 11.2:1. Not the ideal setup. Turbo Feeds: Turbo oil feed can be tapped from one of the 3 bungs near the oil filter. This is direct oil pressure so use a 1mm restrictor if using a ball bearing based turbo. With journal bearing turbo's this is less of a problem. Turbo oil return should be pressure free and as vertical as possible, the return from the turbo can be tapped into the rubber pipe running from the rear of the head on the passanger side down to the block. It will be hidden by a metal plate which can be removed. Water feeds can be tapped from almost anywhere, a good choice would be the oil cooler on the side of the block under the manifold. Simply tap the outlet to the turbo and then back into the block. looking at some dyno figures 275.9kW @ 18psi (though it was dyno in the wrong gear) 270.5KW @ 13.6psi 'could' be the most power you can get out of a blacktop/redtop(maybe?) BEAMS turbo with vvti and lack of aftermarket camshafts to suit situation. -------------------- |

Jul 28, 2011 - 7:02 AM Jul 28, 2011 - 7:02 AM

|

|

|

Enthusiast   Joined Apr 20, '06 Currently Offline Reputation: 0 (0%) |

cant really read anything into those power figures, who knows at what point the cams might need to be changed for more power, and anyway you can still get vvti cams from toda and trd if you want, you'd want a non vvti cam for the exhaust side anyway and there is quite a lot of choice there, less so for the intake side with vvti but still toda do a 268 and trd a 282 duration cam or you could go with a cam from mr booth i'm pretty sure he just gets trd or toda cams and puts his own grind on them anyway.

If your at the power levels the beams cam becomes a restriction i think getting the right cam grind is probably not going to be that big a deal in the grand scheme of things. not really convinced about the idea of going with 2jz pistons either unless it works out mega cheap, would rather go with custom forged pistons from the likes of JE, which isnt too different in price to forged 3s-gte pistons from the quotes i had, or arias have a part number i'm sure for forged beams pistons, by the time you've payed for the machining work on the 2jz pistons and rods it might not be any different. If your feeling flush also g.booth can supply them or you could use toda pistons. |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 26th, 2024 - 11:47 PM |