|

Nov 22, 2012 - 12:36 AM Nov 22, 2012 - 12:36 AM

|

|

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline Reputation: 0 (0%) |

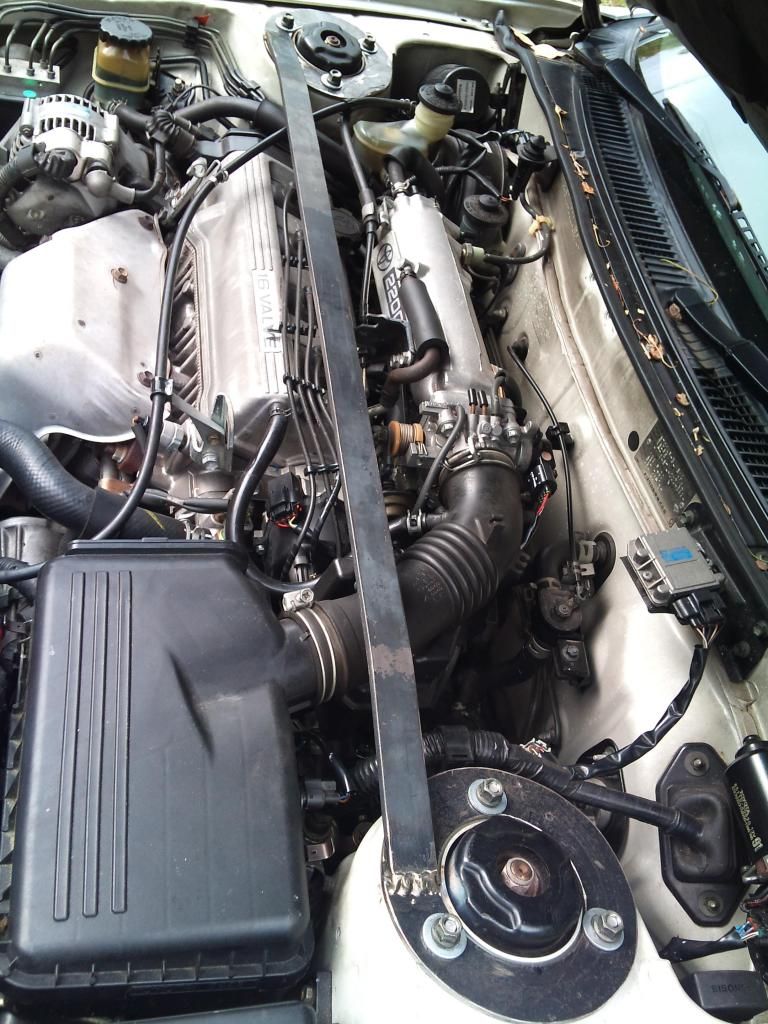

So made a strut bar today all fits perfectly, is beefy as all hell but then I decide to try and shut the bonnet.....

When I was measuring it, I didnt notice the support bars running along the underside of the bonnet and of course with my luck they hit the strut bar preventing me from closing the bonnet So now I need some ideas from you guys on how to modify the strut bar without starting again. My favourite idea is cutting the bar in the middle and bashing the bends at either end down a little but and then re-welding it in the middle. My concern is strength when it is re-welded. OR I can grind off the welds at each end and make the bends a slightly lesser angle. Prefer not to do this one but if its the best option I guess I have no choice. If theres any other ideas you guys/gals can think of let me know or please critique mine just above. It is going to become a 3-pt bar just trying to sort two out first. Here are the pics:

|

Nov 22, 2012 - 2:12 AM Nov 22, 2012 - 2:12 AM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

get a GT4 hood... Tha strut bar looks great!!!!!

what about cut and grind the welds and invert the bar so the u shaped goes down... instead of adding more welds... -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

Nov 22, 2012 - 2:16 AM Nov 22, 2012 - 2:16 AM

|

|

Enthusiast      Joined Dec 22, '06 From Columbia, MD Currently Offline Reputation: 13 (100%) |

you lost me after i read "bashing"

--------------------  1995 GT::::Diffusing the Situation エキサイティングカーレーシングチーム! march 2010 COTM : 6GC feature 2014 : january 2015-2016-2018 COTM |

Nov 22, 2012 - 8:19 AM Nov 22, 2012 - 8:19 AM

|

|

|

Enthusiast   Joined Jan 3, '06 From The Netherlands Currently Offline Reputation: 6 (100%) |

Get rid of the bends and you'll be fine. I would also suggest to keep the stock strutbar for more rigidity

-------------------- JDM ST205

|

Nov 22, 2012 - 10:35 AM Nov 22, 2012 - 10:35 AM

|

|

|

Moderator      Joined Jun 29, '08 From Denver Currently Offline Reputation: 59 (100%) |

That strut bar looks good! Are you able to start over? You could always grind the welds off, cut some of the ends off of the cross bar, make the bends slightly flatter, and reweld. As long as the weld is good, you won't lose any rigidity. Good luck getting it modified!

-------------------- "Employ your time in improving yourself by other men's writings, so that you shall gain easily what others labored hard for." -Socrates. Even Socrates told us to use the search button!

2006 Aston Martin V8 Vantage. 1998 Celica GT- BEAMS Swapped. 2022 4Runner TRD Off Road Prenium. 2021 GMC Sierra AT4. |

Nov 22, 2012 - 11:04 AM Nov 22, 2012 - 11:04 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

flat bar will bow upward under stress.

-------------------- |

Nov 22, 2012 - 11:04 AM Nov 22, 2012 - 11:04 AM

|

|

Enthusiast    Joined Apr 22, '12 From Central NY Currently Offline Reputation: 5 (100%) |

What about if you turn it around so the crossbar is towards the back and re-drill the holes on the mounts? Will it still be in the way?

-------------------- 99 Celica GT-S

91 Subaru Legacy Sport AWD Turbo 2010 Acura RDX Turbo w/ Technology Package 68 Impala SS Convertable |

Nov 22, 2012 - 5:06 PM Nov 22, 2012 - 5:06 PM

|

|

|

Enthusiast   Joined Jul 29, '11 From chino, Ca Currently Offline Reputation: 4 (100%) |

Add some hood spacers dude that's what I did it adds a hood cowl effect cooling the underhood temp.

|

Nov 22, 2012 - 6:53 PM Nov 22, 2012 - 6:53 PM

|

|

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline Reputation: 0 (0%) |

get a GT4 hood... Tha strut bar looks great!!!!!  what about cut and grind the welds and invert the bar so the u shaped goes down... instead of adding more welds... GT4 hood sadly isn't in the budget at the moment. Get rid of the bends and you'll be fine. I would also suggest to keep the stock strutbar for more rigidity A straight bar can't work as it hits a few things along the way and the bends also provide some extra rigidity That strut bar looks good! Are you able to start over? You could always grind the welds off, cut some of the ends off of the cross bar, make the bends slightly flatter, and reweld. As long as the weld is good, you won't lose any rigidity. Good luck getting it modified! Thats what i'm most likely going to have to do and I think is the most logical for a rigid bar. I was just hoping to avoid welding with it on the car again (im scared an electrical spike could kill something) What about if you turn it around so the crossbar is towards the back and re-drill the holes on the mounts? Will it still be in the way? There are other things in the way if its turned around like the intake plenum and theres not enough bonnet clearance to go above it. Add some hood spacers dude that's what I did it adds a hood cowl effect cooling the underhood temp. Never heard of them, anyone got pics? Thanks for the replies guys! keep them coming! |

Nov 22, 2012 - 10:24 PM Nov 22, 2012 - 10:24 PM

|

|

Enthusiast      Joined Dec 22, '06 From Columbia, MD Currently Offline Reputation: 13 (100%) |

Add spacers to the bolts that attatch your hood. You can only put on so many before the bolt doesn't have enough threads to grab. I may have a couple pics of my setup in my build thread, but your be able to get a better idea of how it looks by googling hood spacing

--------------------  1995 GT::::Diffusing the Situation エキサイティングカーレーシングチーム! march 2010 COTM : 6GC feature 2014 : january 2015-2016-2018 COTM |

Nov 22, 2012 - 10:39 PM Nov 22, 2012 - 10:39 PM

|

|

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline Reputation: 0 (0%) |

Ye, had a look and didn't wanna do the hood spacers.

I decided to grind off the welds and re-do it. You can see from the photos that i had to put it slightly more centered so it started lower to avoid hitting the bonnet bracing. Funny story now, I'm half under the car trying to measure it up nicely when my mum comes out and just says why dont you put chalk on the top of the bar then close the bonnet and see where it hits. I thought why not lets give it a go, so the process then became trial and error to find an angle that worked. To finish it off I lined the bar up with blueberries and closed the bonnet to see that none were getting squashed! moral to the story, get your mum to help more often haha. Anyhow here are the pics of the 2-pt so far and ill get onto making the other points soon!    And the main difference between last time:  YAY! lol Thanks again for the suggestions guys! |

Nov 23, 2012 - 1:45 AM Nov 23, 2012 - 1:45 AM

|

|

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline Reputation: 0 (0%) |

And then 2-points became 3!!

Havent test driven it yet, going to give it a coat of paint first! |

Nov 23, 2012 - 3:33 AM Nov 23, 2012 - 3:33 AM

|

|

Enthusiast     Joined Oct 29, '11 From Haltom City, Texas Currently Offline Reputation: 1 (100%) |

Dont paint it, sand it and clear coat it, it will look like chrome or stainless depending on how much sanding you do

|

Nov 23, 2012 - 4:47 AM Nov 23, 2012 - 4:47 AM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

The fab work looks pretty good, but as was stated before the flat bar is going to flex. Tube, even a thin aluminum tube like the cusco or trd is going to be more rigid than a steel flat bar. As far as the bends go, the rigidity in shape you might be gaining, you are losing with longer bar length. I am not trying to nit pick and props for making one, I just think with a little more rigid material you could make it a lot stronger and lighter. You might look at places like

mcmastercarr for tubing ideas. -------------------- JDM guy made me do it.

|

Nov 23, 2012 - 9:32 AM Nov 23, 2012 - 9:32 AM

|

|

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline Reputation: 0 (0%) |

Dont paint it, sand it and clear coat it, it will look like chrome or stainless depending on how much sanding you do I love the idea, but hate you for suggesting it haha coz its so much work The fab work looks pretty good, but as was stated before the flat bar is going to flex. Tube, even a thin aluminum tube like the cusco or trd is going to be more rigid than a steel flat bar. As far as the bends go, the rigidity in shape you might be gaining, you are losing with longer bar length. I am not trying to nit pick and props for making one, I just think with a little more rigid material you could make it a lot stronger and lighter. You might look at places like mcmastercarr for tubing ideas. Ye I was thinking that but as I had that lying around in the garage I thought why not, plus anything is better than that stock decorative item which does NOTHING! |

Nov 23, 2012 - 4:08 PM Nov 23, 2012 - 4:08 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

Replace the bar with tube and you have a nice design.

-------------------- |

Nov 23, 2012 - 8:12 PM Nov 23, 2012 - 8:12 PM

|

|

|

Enthusiast  Joined Sep 30, '11 From Sydney Currently Offline Reputation: 0 (0%) |

Ok guys, since i'm studying mechanical engineering at uni i have access to simulation software and did a quick comparison between flatbar, square tube and circular tube for a 2 point bar.

Here are the results and are as expected really, but i'm still not gonna change my design. The tests were run using a force of 5000N at each end of the bar putting it in compression. No idea what they are actually experiencing. This test is also a big simplification assuming that the bar is free to slide in the axis that it sits (parallel to the engine). So this wont actually be the deflections happening under your bonnet, just showing people the difference in the cross sections. The dimensions are: Flatbar - 32x8mm Round tube - Outside diameter 20mm, inside diameter 18mm Square tube - 20x20x2mm

|

Nov 23, 2012 - 10:06 PM Nov 23, 2012 - 10:06 PM

|

|

Enthusiast      Joined Jul 12, '08 Currently Offline Reputation: 5 (100%) |

Have you used Abaqus before?

This post has been edited by enderswift: Nov 23, 2012 - 10:07 PM --------------------  |

Nov 23, 2012 - 10:34 PM Nov 23, 2012 - 10:34 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

interesting, i would run it again with a straight bar, I think the bend would cause more deflection than a shorter straight bar.

Just a guess, I have no software to test this, but I have been making parts on cnc mills for 20 years, so understanding rigidity is something I have tried a time or 2. afaik the bend seen in some bars is a clearance thing for top mount IC, I doubt it is adding any rigidity. Bicycle frames and forks are a good example of rigidity in action, the materials used have a lot to do with it also. Chrome moly should be a great strut bar material imo. -------------------- JDM guy made me do it.

|

Nov 23, 2012 - 10:57 PM Nov 23, 2012 - 10:57 PM

|

|

|

Enthusiast      Joined Mar 15, '07 From Tennessee Currently Offline Reputation: 52 (100%) |

flat should be fine...

i would add the little triangles at the end of mine -------------------- Learned a lot in 10 years... I hardly log in anymore, last login Today Sept 6 2019, and I was forced just to clarify a post. LOL

If you PM me and I dont respond, dont fret or cry. Im alive, better post your questions in the thread below, maybe I log back in 2grfe Swapped... Why I chose the 2GR, before you ask read here... A great civilization is not conquered from without until it has destroyed itself from within. @llamaraxing in Instagram is the best way to find me. I hardly log here anymore. |

|

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: December 1st, 2024 - 6:48 PM |