|

Dec 16, 2012 - 1:28 PM Dec 16, 2012 - 1:28 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

I was certain I started a build thread on here, but for the life of me I can not find it so forgive me if I start again and its old news.

About a year and a half ago my current GT4 failed its yearly inspection (MOT) with rusty sills, they were fixed and it subsequently passed but it set alarm bells ringing in my head that the poor things days were numbered. I decided that I would buy a shell and swap everything onto it. so I hunted for a reasonable shell to start work on. While I was looking, I had to extend my garage. I only had a single car garage so not enough space to work or store stuff. So I decided to extend my garage backwards a bit Work started.  and after a few weeks, finished ;0   About the same time a shell turned up, well it was sold as a shell, but it was more or less a complete car minus the engine and gearbox.    It was in good condition with no rust, even the interior was in pretty much spot on condition, not that I need much of it   I set to wrok more or less straight away  First job was to strip everything off the car  everything went, all the looms, glass, suspension the works  Next job was to remove the sound deadening material   it then went outside for a thorough jet wash go get rid of all the years of crap   As I was moving the battery to the inside I could remove the battery tray  which I did   Next up I needed to get to the bottom of the car....this was going to require some ingenuity. -------------------- |

Dec 16, 2012 - 1:38 PM Dec 16, 2012 - 1:38 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

I was going to have to make my own rotisserie.

So ack off to the wood yard, a few lengths of 2x4 and I made this  It was about now I realised two things. One I was going to have to learn to weld and two..my plans for this car were changing quite dramatically......a fancied making a cross between a rally car and a GT car...no idea how I was going to achieve this, but the seeds had been set in my mind and for once they stayed there. So I rushed out and purchased a MIG welder....learning to weld was pretty easy to be honest, by no means as neat as the pros but not bad for a complete novice. So I made a rotisserie  It fitted like a glove and worked perfectly  A quick look revealed the sills were pretty mangled  so I had to fix them up as best I could  At the same time I started blasting and painting with good old POR15 the subframes and suspension parts  The came out quite nice  did the prop shaft too, started a bit rough  came up well  also cleaned up the steering rack  and the alloy diff end plate....gave it a good polish  Next up I started the worst job I have ever attempted -------------------- |

Dec 16, 2012 - 1:45 PM Dec 16, 2012 - 1:45 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

Tackling the stone guard on the bottom of the car.

I cant count the amount of drill & angle grinder wire brush attachments I have gone through. it makes alot of dust and takes what seems like forever   slow slow work  this stage took about a month  at last, more or less done   I then painted it with more POR15  More or less at the time I was ready to slit my wrists due to constant wire brushing the roll cage turned up (I still havnt finished under the car....I am going to get the rest sand blasted....i just cant face it any more  A brief test fitting and I was starting to get excited.....I was going to have to break out the welder again

-------------------- |

Dec 16, 2012 - 1:54 PM Dec 16, 2012 - 1:54 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

First job was to add some strengthening to the top of the rear suspension tops, so i removed the odd metal bracing off them (i think its used to just hold the rear plastics in place?)

I then made a template  and then a metal top (3mm mild steel)  and one for the other side  Once I had welded these to the car it was time to start getting the roll cage in  I filled the aerial hole whilst I was at it  Anyway, back to the cage, more bits turned up  this was starting to get serious    this ties in the rear sub frame to the cage, helps keep things stiff  nearly there  as you can see my welding isnt great, but as its more or less the seond thing I have ever welded in my life i was mildly pleased with it  Done  i had decided that I didnt want a full cage, at the end of the day it will be just a road car so getting in and out easily is a priority Next up I decided it was about time to learn how to cast new metal parts, as for what I had in mind the parts do not exist, I was going to have to make them. -------------------- |

Dec 16, 2012 - 1:59 PM Dec 16, 2012 - 1:59 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

I was going to have to make myself a mini blast furnace...and learn how to cast metal

I needed these  I turned the bin into a furnace with the use of some fire cement   fill it with charcol, attach a heat gun, ignite and stand back  I made a vessel from a spare piece of square tube...it gets pretty hot  hot enough to melt alloy  I still needed to learn how to make sand moulds so stopped there for the time being, I will pick that up again later. -------------------- |

Dec 16, 2012 - 2:06 PM Dec 16, 2012 - 2:06 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

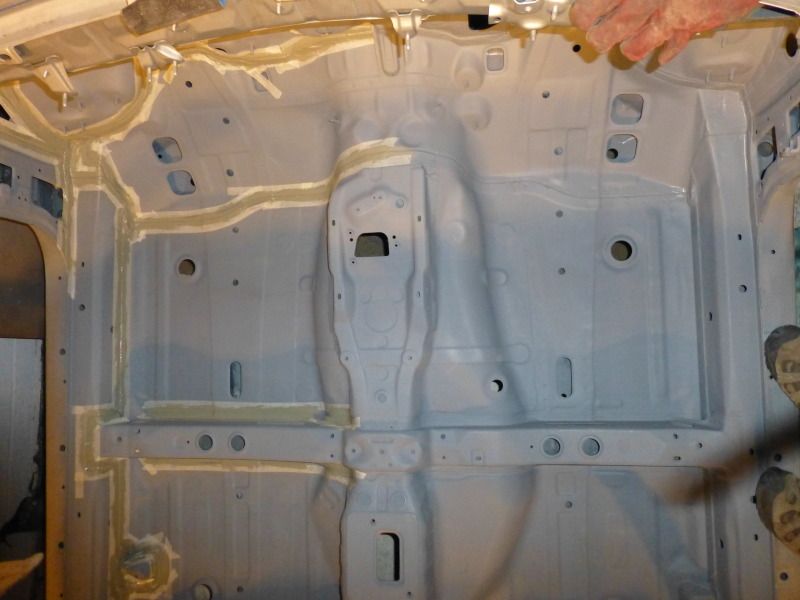

Taking a long look at my roll cage, I was not happy with the welds. so i decided to dress them, smooth them out, add a little body filler and make them smooth

started looking much better although I did have to remove the main hoop cross member for access  dont worry its not going to be that colour, thats just filler primer  at the same time I cleaned up the floor and primed that ready for paint  the boot aswell....I also welded the cross member back in   Next up was the seam sealer, so I masked off the areas I was going to apply it to  then applied the U-Pol grey stripe seam sealer (nasty stuff)   and that is about where I am up to today. Just been out into the garage to remove the masking tape. it looks a bit messy, but when its primed over the top you can hardly tell its there. I will add more pictures when I have taken them. I will update when I get a chance but I work pretty slowly so dont expect much. hope I havnt bored you to death more to come Nial -------------------- |

Dec 16, 2012 - 2:19 PM Dec 16, 2012 - 2:19 PM

|

|

Enthusiast      Joined Mar 8, '04 From Newport, RI Currently Offline Reputation: 63 (99%) |

Great job.

That's a ton of work, impressive. -------------------- |

Dec 16, 2012 - 10:18 PM Dec 16, 2012 - 10:18 PM

|

|

|

Enthusiast     Joined Mar 8, '09 From Westport, MA Currently Offline Reputation: 6 (100%) |

Not your everyday build, excellent job so far man.

-------------------- st205 powered ss3 coupe

|

Dec 16, 2012 - 10:43 PM Dec 16, 2012 - 10:43 PM

|

|

Enthusiast      Joined Dec 22, '06 From Columbia, MD Currently Offline Reputation: 13 (100%) |

super diy!!

--------------------  1995 GT::::Diffusing the Situation エキサイティングカーレーシングチーム! march 2010 COTM : 6GC feature 2014 : january 2015-2016-2018 COTM |

Dec 17, 2012 - 12:47 AM Dec 17, 2012 - 12:47 AM

|

|

|

Enthusiast      Joined Jun 18, '09 From Orlando Currently Offline Reputation: 8 (100%) |

-------------------- '97 ST \ Eibach \ KYB \ Kenwood \ Alpine \ Cusco \ OEM+ [sold 10/18]

'93 MX-5 LE |

Dec 17, 2012 - 5:06 AM Dec 17, 2012 - 5:06 AM

|

|

Enthusiast      Joined Feb 3, '06 From Czech Republic (Europe) Currently Offline Reputation: 56 (100%) |

You are unbelievable Nial

-------------------- No more replicas... This is evolution... This is SS-four :)

________[Featured Celica of 6gc.net @ 2010]_________ |

Dec 17, 2012 - 5:32 AM Dec 17, 2012 - 5:32 AM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

Thanks all, glad you like it

You are unbelievable Nial Cheers. means alot from a fellow faffer This post has been edited by Nial: Dec 17, 2012 - 6:05 AM -------------------- |

Dec 17, 2012 - 6:28 AM Dec 17, 2012 - 6:28 AM

|

|

Enthusiast  Joined Jul 5, '12 From Barcelona Currently Offline Reputation: 0 (0%) |

Looks great! It'll be like new!

Just one thing I was wondering about. I don't know much about roll cages, but it is my understanding that if you put in racing seats and harnesses you'll need a horizontal shoulder height beam to attach the harnesses to (the reason being, to avoid spinal compression in the event of an accident). Have you considered this? --------------------  |

Dec 17, 2012 - 6:41 AM Dec 17, 2012 - 6:41 AM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

Looks great! It'll be like new! Just one thing I was wondering about. I don't know much about roll cages, but it is my understanding that if you put in racing seats and harnesses you'll need a horizontal shoulder height beam to attach the harnesses to (the reason being, to avoid spinal compression in the event of an accident). Have you considered this? I will be using normal belts, If I want to use a racing harness I will attach it to the rear strut brace as the Rally Cars did. as they lie within the tollernece angles to avoid such injuries. -------------------- |

Dec 17, 2012 - 10:36 AM Dec 17, 2012 - 10:36 AM

|

|

|

Moderator      Joined Jun 29, '08 From Denver Currently Offline Reputation: 59 (100%) |

Great work so far! I can't wait to see where this goes.

-------------------- "Employ your time in improving yourself by other men's writings, so that you shall gain easily what others labored hard for." -Socrates. Even Socrates told us to use the search button!

2006 Aston Martin V8 Vantage. 1998 Celica GT- BEAMS Swapped. 2022 4Runner TRD Off Road Prenium. 2021 GMC Sierra AT4. |

Dec 18, 2012 - 4:45 AM Dec 18, 2012 - 4:45 AM

|

|

Enthusiast   Joined May 9, '09 From Brisbane, Australia Currently Offline Reputation: 0 (0%) |

Nice work! Can't wait to see the finished product.

-------------------- |

Dec 18, 2012 - 2:23 PM Dec 18, 2012 - 2:23 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

I dont know if you guys like small regular updates, or big updates every yew months?

well here is a little update. I just about finished the seam sealer today but to show you a comparison, one side of the car is finished and the seam sealer has been primed, the other side it has just been applied.  Left side it has just been applied, right side has had two coats of seam sealer and had primer sprayed over the top. I am pleased that you can hardly see anything despite the fact it will all be covered over with sound mat.....just because you cant see it dosent mean it cant be right. cheeky shot of the cage

This post has been edited by Nial: Dec 18, 2012 - 4:02 PM -------------------- |

Dec 18, 2012 - 6:00 PM Dec 18, 2012 - 6:00 PM

|

|

Enthusiast      Joined Jul 12, '08 Currently Offline Reputation: 5 (100%) |

QUOTE just because you cant see it doesn't mean it cant be right This is how I know this thread will be good --------------------  |

Feb 25, 2013 - 3:47 PM Feb 25, 2013 - 3:47 PM

|

|

Enthusiast    Joined Aug 25, '08 From England Currently Offline Reputation: 1 (100%) |

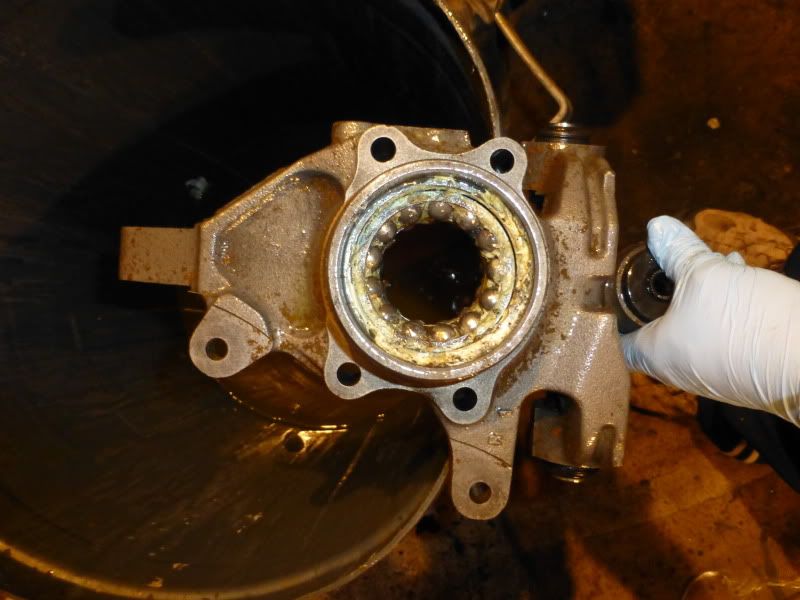

I have been busy recently, but have found some time to spend on this project.

I stripped down the petrol tank  gave it a good paint  the obligatory walbro fuel pump  all back together with some stainless steel bolts  rejuvenated the fuel tank straps   started rebuilding the rear axels  managed to rescue the rear brake disc backing plates  they came up well  Found a product called Deox C which is great at getting rid of rust, bought the rear hub carriers up a treat  and I got alot of bolts zinc plated   and the door catches chromed  things are starting to go back together now, the rear subframe and suspension parts are all half built, just waiting for the paint on the rear hubs to dry and cure and they can go back together, need some snap rings for the rear axels, then they can go back on. Rear diff can be completed tomorrow if I get time. -------------------- |

Feb 25, 2013 - 4:10 PM Feb 25, 2013 - 4:10 PM

|

|

|

Enthusiast Joined Sep 10, '08 From UK Currently Offline Reputation: 0 (0%) |

absolutely epic Nial, top work.

fancy doing my car when your done with this one? |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 25th, 2024 - 11:07 AM |