|

Jan 1, 2017 - 3:01 PM Jan 1, 2017 - 3:01 PM

|

|

Enthusiast      Joined Jul 12, '08 Currently Offline Reputation: 5 (100%) |

It's really hard to kill a 3SGTE. They can take a beating all day long in triple digit heat without issue. I boost 20+ psi on my 3rd gen and bang through the gears at 7k on my commute to work. I've been doing this for the past 40k....These engines are STRONG

In my opinion your engine was knocking and you didn't realize it. The reason I say this is because a common symptom of knock is rising coolant temps. knock breaks through the thin insulating film in the combustion chamber and exposes the cylinders to the full heat combustion, thus raising temps.Don't believe such an insulating film exists? ask yourself how an aluminum piston doesn't melt during normal driving... Also the stock cooling setup can handle the 3sgte no problem. So considering you replaced everything and yet the temps still rose, I'd say knock was dumping heat into the system. Knock also puts crank and connecting rod bearings through hell, leading to similar damage to oil starvation. It look like you know what you're doing, and I'm not insulting the quality of your build. I just want to convey that knock can be sneaky and lead to a situation like this. QUOTE I think I got a bad 4th gen 3sgte (bad head gasket and worn piston rings). I was only running 14 psi and when the car started overheating and knocking. I wasn't in boost and I have put a total of 1000k miles on this motor since the swap (did my first oil change at 500 miles to make sure any crap that had settled in the motor was out) Only a compression test, leakdown test, or hydrocarbon test can confirm whether your head gasket/rings are shot. Thing is, a knocking engine can absolutely cause both of these as well. Anyway, I only raise boost with the proper supporting mods in place. Colder plugs and water injection are good for staving off knock into the low 20 psi range. A handful of other guys on here will agree. Consider doing the same if you get a replacement engine Good luck This post has been edited by enderswift: Jan 1, 2017 - 3:01 PM --------------------  |

Jan 1, 2017 - 5:15 PM Jan 1, 2017 - 5:15 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

Thanks for the information. I am wondering what was causing the knock. I have been running colder NGK BKR7E plugs and I was having heat issues even when the engine was set at 7 psi before I ran a boost controller. Like you said, it is hard to kill a 3sgte, and with me taking it a lightly as a did for these initial miles, I am really thinking I was sold an engine that was not well taken care of by the previous owner. Most people run 16 psi with no problems on these engines with the exact set up I have. I read that the PRIMEMR2 guys run into this occasionally where they get a 4th gen that is either dead or dying. Just my bad luck.

I know hindsight is 20/20 but I really wish I would have took the cylinder head off and inspected the pistons and bearings with a little more detail. Sure it would have cost me at a minimum a head gasket but it would have given me piece of mind. Looking back I did notice a dark yellowish/orange tint to the cams and cylinder head under the valve cover. That is a telling sign of a higher mileage or abused engine, maybe over 60K miles like advertised to me. Also, now that I think about it, the highest Octane around here is 91, could that have caused the knock problem? It may be something other than the gas because I was having heat issues at 7 psi. Like I said in the previous post, I was having some large amounts of oil in the blow by even while not on boost, is that normal? I am really hoping when I pull the engine that there is not too much scaring on the crankshaft so I can get it machined. I am definitely leaning towards rebuilding the motor with forged rods and pistons. Even if I get another motor because I cannot save this one, I am going to rebuild it with forged internals before I put it in. I am not going to sit back and hope my next JDM motor was treated well before it was handed to me. But who knows, I am still not against selling the car and getting another project down the road. This post has been edited by HardHead93: Jan 1, 2017 - 5:19 PM |

Jan 3, 2017 - 9:54 AM Jan 3, 2017 - 9:54 AM

|

|

|

Enthusiast      Joined Jan 20, '09 From Winnipeg Currently Offline Reputation: 5 (100%) |

I would definitely contact the company that sold you the motor. Regardless if it was an issue that they sold you, or something that occurred while the motor was in your possession, it doesn't hurt to try. maybe they will be accommodating and help you out. I had a buddy who bought a skyline that a company imported, blew the motor within two weeks, and they helped him source a new engine and rebuild at a discounted rate, so you never know.

It really sucks that this has happened after you've put so much time and effort into it. I'd hate to see you give up and simply sell the car though -------------------- -Protection mode, For when your amp tries to blow its load. 1995 Toyota Celica GTS - Daily Driver 1999 Chevy Cavalier - Winter Beater 1994 Honda Civic CX Hatchback - Dead My Celica! |

Jan 13, 2017 - 8:29 PM Jan 13, 2017 - 8:29 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

So after a lot of cussing, kicking, and screaming, I decided to get back to work on fixing this car. I pulled the motor and broke it all the way down to determine what failed.

Mostly apart:  Cylinder head looks pretty worn and I am not liking all that black on the intake cam:  The bare 3s block:  All the 3sgte parts:  Engine bay:  What I found was rod knock on cylinder #1. The rod was black from the excessive heat. I inspected all the rods and it looked as if the previous owner of the car either did not take care of the engine or there was more than 60K mile on the motor. When I opened up my 130K mile 5sfe, the bearings did not look as worn as these ones. Oh well, time to move on. I decided to get another 3sgte instead of rebuilding the other one. I just got it in today and hopefully this time it will go well. Here is the 3s on the truck once I got home from the warehouse:  Now on the ground next to the 3s block:  Another shot of the 2nd 3sgte:  I will swap over parts that I replaced from the other 3sgte. Then replace the oil pump and rear main seal and drop the engine back in. My goal is to have this all done by the end of the 3 day weekend. (Deep breath) Time to get to work! This post has been edited by HardHead93: Jan 13, 2017 - 8:32 PM |

Jan 15, 2017 - 8:18 PM Jan 15, 2017 - 8:18 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

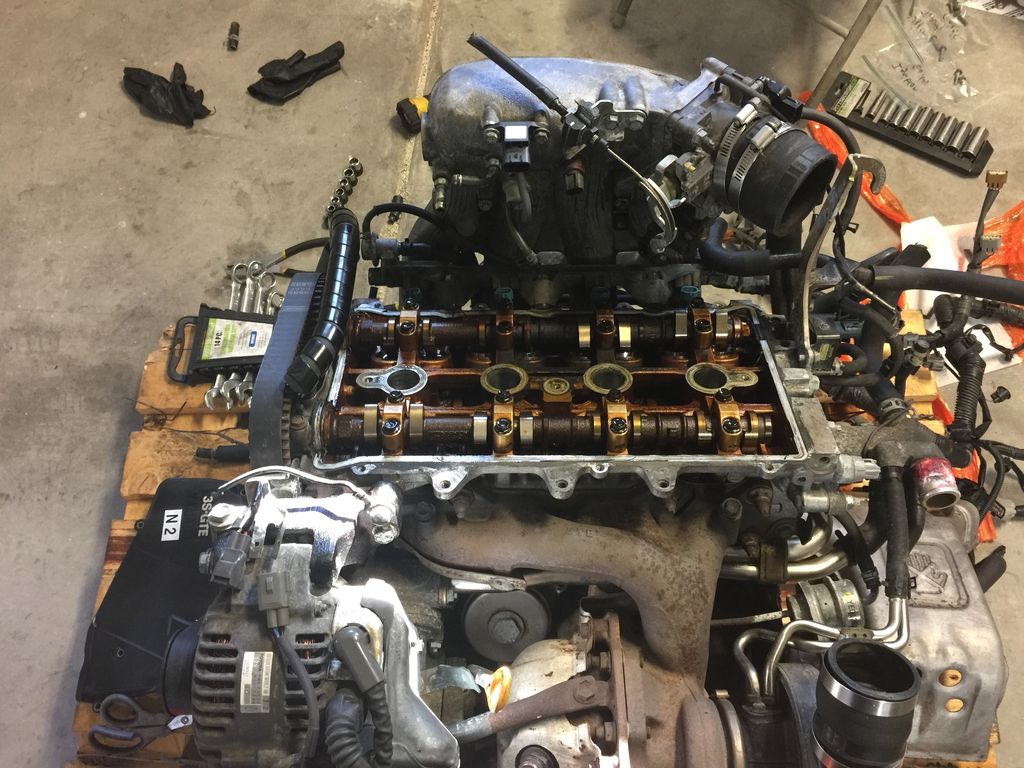

So I am part way through getting the motor ready for the car. It looks like the first 3sgte I bought was severely worn out. I figured this out when I took off the valve cover on the 2nd motor I got. Here is the 1st motor with the valve cover off:

Here is the 2nd motor with the valve cover off:  There is a BIG difference between the two. I found this write up on the Wiretap site that tells you what to look for in a motor and to determine its quality. http://www.wiregapinc.com/2013/02/buying-a-used-motor/ As you can see the first motor has a lot of dark yellow and black coloration in the cylinder head which means the engine should have been rebuilt before it was put into the car. Less than 60K miles my a**! On the 2nd motor it also looks like someone has recently replaced the water pump. The pump looks almost brand new. Score!!!!  I am finishing up replacing the oil pump and rear main seal then I will drop the engine back in. |

Jan 16, 2017 - 1:25 AM Jan 16, 2017 - 1:25 AM

|

|

|

Enthusiast   Joined May 2, '15 From NY Currently Offline Reputation: 3 (100%) |

I hope you were able to get at least some money/discount back on the crap motor... Sure, you can part it out, but that takes lots of time and good amount of effort before you see that money back.

Props on determination. Let's hope you've got enough karma points with the car by now that it will let you have some fun at last. |

Jan 17, 2017 - 11:42 AM Jan 17, 2017 - 11:42 AM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

|

Jan 17, 2017 - 12:15 PM Jan 17, 2017 - 12:15 PM

|

|

Enthusiast  Joined Jan 10, '17 From Russia, Izhevsk Currently Offline Reputation: 0 (0%) |

Good luck to you.

Perhaps it was necessary to immediately change the path for the connecting rods 3 gene. What do you think? -------------------- Email - vad07@inbox.ru

|

Jan 21, 2017 - 1:49 PM Jan 21, 2017 - 1:49 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

I have the engine back in the car, here is a video of one of my first starts:

https://www.youtube.com/watch?v=9wVM86aUXhY Maybe I am being paranoid but when the engine is completely warm, I am hearing a very faint ticking. Does anyone know what it could be? I hope it is not another bearing. |

Jan 21, 2017 - 11:39 PM Jan 21, 2017 - 11:39 PM

|

|

|

Enthusiast   Joined May 2, '15 From NY Currently Offline Reputation: 3 (100%) |

I have the engine back in the car, here is a video of one of my first starts: https://www.youtube.com/watch?v=9wVM86aUXhY Maybe I am being paranoid but when the engine is completely warm, I am hearing a very faint ticking. Does anyone know what it could be? I hope it is not another bearing. My guess is valve tick - valve clearances a bit high. Happens to my 5S when warmed up, such as after a lengthy drive. Not a big deal - may be a tad down on power due to valves open less than designed, but that's about it. May want to check at some point. |

Jan 22, 2017 - 10:49 AM Jan 22, 2017 - 10:49 AM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

I have the engine back in the car, here is a video of one of my first starts: https://www.youtube.com/watch?v=9wVM86aUXhY Maybe I am being paranoid but when the engine is completely warm, I am hearing a very faint ticking. Does anyone know what it could be? I hope it is not another bearing. My guess is valve tick - valve clearances a bit high. Happens to my 5S when warmed up, such as after a lengthy drive. Not a big deal - may be a tad down on power due to valves open less than designed, but that's about it. May want to check at some point. I plan to check the valve clearances and replace the rod bearings today just to be safe. I have already done a compression test and double checked the gaps on my spark plugs. The compression test came out with 160-180 psi on all cylinders. I am using NGK copper plugs gapped to 0.028. This post has been edited by HardHead93: Jan 22, 2017 - 11:42 AM |

Jan 22, 2017 - 12:24 PM Jan 22, 2017 - 12:24 PM

|

|

Enthusiast  Joined Jan 10, '17 From Russia, Izhevsk Currently Offline Reputation: 0 (0%) |

Do not you have disassembled the engine before putting it on the machine?

Obviously, this had to be done. check the status of the pistons, rings, liners, rubber seals. Before installation, set the valve clearances. You just set it and run? -------------------- Email - vad07@inbox.ru

|

Jan 23, 2017 - 11:25 PM Jan 23, 2017 - 11:25 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

|

Jan 24, 2017 - 1:17 AM Jan 24, 2017 - 1:17 AM

|

|

Enthusiast  Joined Jan 10, '17 From Russia, Izhevsk Currently Offline Reputation: 0 (0%) |

Why sealant black? At Toyota it is usually red.

-------------------- Email - vad07@inbox.ru

|

Jan 24, 2017 - 4:40 PM Jan 24, 2017 - 4:40 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

|

Jan 24, 2017 - 8:58 PM Jan 24, 2017 - 8:58 PM

|

|

|

Enthusiast   Joined May 2, '15 From NY Currently Offline Reputation: 3 (100%) |

That engine looks squeaky clean.

All you gotta do now is try to put it all behind and drive the hell out of it. Every time someone comments on my driving style, my response is: I fix them hard, I drive them hard. |

Jan 25, 2017 - 11:21 PM Jan 25, 2017 - 11:21 PM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

The car is now back together and running. I just finished burping the coolant system and plan to take it out for a drive tomorrow. I switched back to my 2 row radiator and got rid of the aftermarket fan shroud. After doing some research an aftermarket fan shroud needs to be 1.5 inches deep or else the radiator will not get enough air flow. I decided to mount the fans directly to the radiator because that is the best option if you cannot find a quality shroud. I noticed the car cooled down even better than the stock radiator with the stock fan shrouds. Also the fans kicked on sooner and moved more air than the stock fans. AWESOME! Here is a pic of both radiators side by side:

This post has been edited by HardHead93: Jan 25, 2017 - 11:22 PM |

Jan 27, 2017 - 10:11 AM Jan 27, 2017 - 10:11 AM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

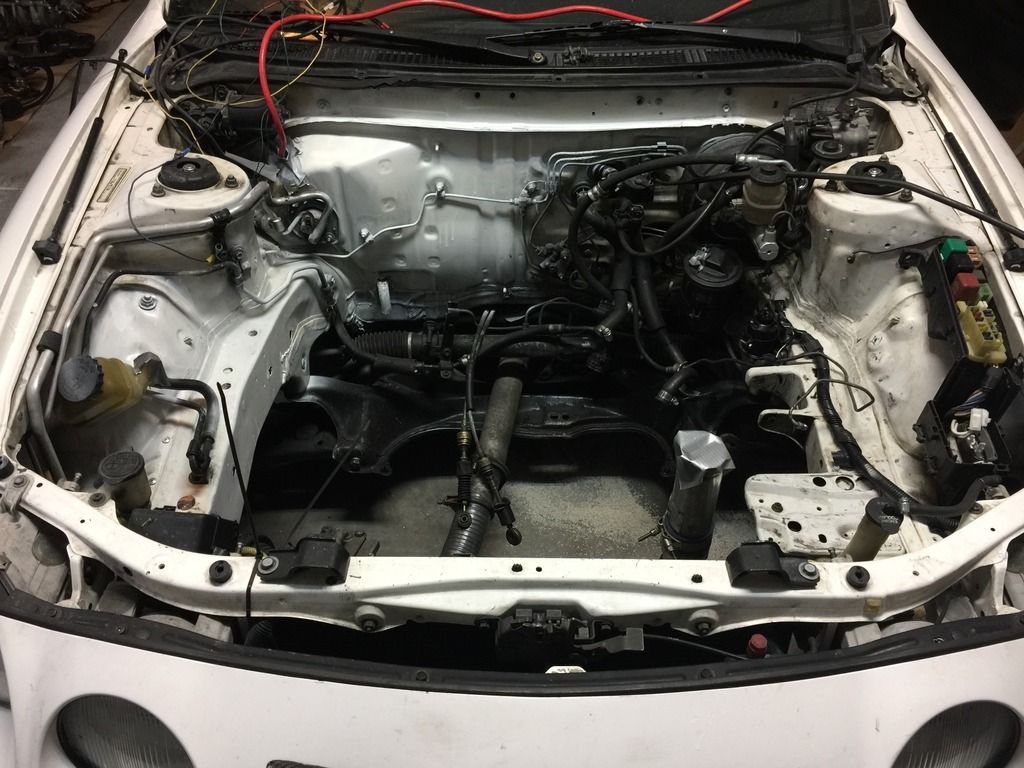

So I have engine #2 in the car and running. Here is a pic of it:

I decided to put an oil catch can on this motor so no blow by oil would get into the turbo and the intake. The catch can I bought has the option to be run either with or without a filter on it. What is better, a sealed catch can or one with a filter on top? |

Jan 31, 2017 - 8:42 AM Jan 31, 2017 - 8:42 AM

|

|

|

Enthusiast   Joined Apr 7, '15 From New Mexico Currently Offline Reputation: 0 (0%) |

So I found this old thread on oil catch cans.

http://www.6gc.net/forums/index.php?showto...65248&st=20 It still isn't clear if a 3sgte should have a sealed or vented catch can. |

Jan 31, 2017 - 1:55 PM Jan 31, 2017 - 1:55 PM

|

|

|

Enthusiast   Joined May 2, '15 From NY Currently Offline Reputation: 3 (100%) |

I'm not sure if I have this topic completely understood, but here's where my thinking lies at the moment:

I would do sealed (and am going to when I to finally installing my catch can). You have two hoses: VC to manifold, with a check valve in between VC to vacuum side of intake (after filter), no check valve Under vacuum, airflow goes intake - vc - manifold. Vacuum is higher in the manifold than further up the line in the intake, so the pressure differential causes the air flow through the PCV system. Under boost, check valve in first hose closes (so as not to pressurize the crankcase) and air goes VC to intake pre-turbo vacuum. The second scenario is where most of the oil covering your intake and intercooler comes from (assuming turbo isn't leaking). Hence, I'm going to put the catch can on the VC to intake hose line. Vents I believe are for either NA cars or older systems that were not closed loop from the factory. If you put a vented catch can on 3sgte you will have eliminated the vacuum pulling the crankcase gasses and would just allow the crankcase pressure release on it's own - a less effective system, if you ask me. Hope this helps. EDIT: Couldn't get it out of my head, kept researching. Turns out, if you "vent" the catch can to atmosphere, you'll have essentially created an unmetered vacuum leak under vacuum. Now, this would've been an issue with Gen2, which had the A/F meter, but probably has much less effect on MAP based Gen4. Still, something to consider for EFI systems. This post has been edited by slavie: Jan 31, 2017 - 3:30 PM |

|

3 User(s) are reading this topic (3 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 15th, 2024 - 2:50 AM |