|

Oct 3, 2006 - 7:46 PM Oct 3, 2006 - 7:46 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

i'm trying to make a short shifter, per mywhite94celicagt's how-to,

http://www.6gc.net/howto/make_custom_short_shifter and i've hit a couple of issues. i pm'ed him a few days back and he hasn't gotten back to me, so i figured i'd ask everyone else. does anybody know what size/length the pin pressed into the side of the ball is? (the one that holds it in place on the lever) i've drilled well past the o.d. of the main lever, and it still won't move when i smack the top of it with a punch. help! EDIT: i figured it out, see below. this will now be my thread for progress on the project. the goal is a functional short shifter for a paltry 15 bucks. that's using a spare, you could do it to your own FO' FREE. i'll have a spare, who knows...maybe i'll make another and sell it! EDIT TWO: really, i just want to spread the love. this is a pretty easy mod you can save yourself at least $40 by doing. This post has been edited by uberschall: Oct 3, 2006 - 11:02 PM --------------------  do you know who i am, mr. worley? |

Oct 3, 2006 - 8:03 PM Oct 3, 2006 - 8:03 PM

|

|

|

Enthusiast      Joined Jul 27, '06 From Soda Currently Offline Reputation: 9 (91%) |

is this the lever u bought from me? GL on the custom ss.

--------------------  |

Oct 3, 2006 - 8:51 PM Oct 3, 2006 - 8:51 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

yup, the very same.

cheaper than a quickshifter by alot, and cheaper than a 7th gen by enough. (the 7th gen ss is straight, and i prefer the e-brake handle clearance the little bend provides thanks for the hookup. u gonna leave me feeback, btw? --------------------  do you know who i am, mr. worley? |

Oct 3, 2006 - 8:53 PM Oct 3, 2006 - 8:53 PM

|

|

|

Enthusiast      Joined Jul 27, '06 From Soda Currently Offline Reputation: 9 (91%) |

oh i did leave a feedback? you didn't get it? ill try again

--------------------  |

Oct 3, 2006 - 9:11 PM Oct 3, 2006 - 9:11 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

got it, thx block!

anyway, i've paused my progress on the shifter.... by looking at the pictures in the how-to, it doesn't appear that i have to drill ALL the way through the shaft to remove the pin. the only way to effectively shorten the throw is to extend the lower part, so i have to move it somehow. any ideas are welcome. --------------------  do you know who i am, mr. worley? |

Oct 3, 2006 - 10:45 PM Oct 3, 2006 - 10:45 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

okay, i went berserk and got it sorted out.

stay tuned, tomorrow i'm going to hit it with the mig and probably get it in the car on thursday. for those of you who might be interested in this mod, additions to the how-to are the following: 1. when drilling out the pin, you should use a bit the size of the funnel-shaped part of the hole in the ball. 2. use a feeler guage to determine how deep you've gone with the drill, you only need to drill until you hit the shaft. 3. after you've cut off the top part and you're ready to tap the lower shaft down, secure the part in something with a cylindrical hole only slightly bigger than the shaft and smaller than the ball (obviously). i used a piece of galvanized pipe clamped securely in a vise. if you use anything that's not round, you're going to leave some nasty witness marks on the ball that you'll have to smooth out afterwards. 4. don't be afraid to smack the living crap out of the punch, the shaft is wedged pretty tight. if necessary, drill a pilot hole for the head of the punch. (that's where i got stuck, the thing wouldn't move) 5. the more of the lower shaft you push out, the more likely you are to run into spacing issues with the floorpan. i only pushed it out about 1/2" to avoid any clearance problems. 6. welding is the best option when re-attaching the upper shaft, with the bend opposite the side actuator arm. i wouldn't trust quick steel, jb weld, or anything else. if that thing busts loose on the freeway, you're up the proverbial creek! --------------------  do you know who i am, mr. worley? |

Oct 4, 2006 - 4:37 PM Oct 4, 2006 - 4:37 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

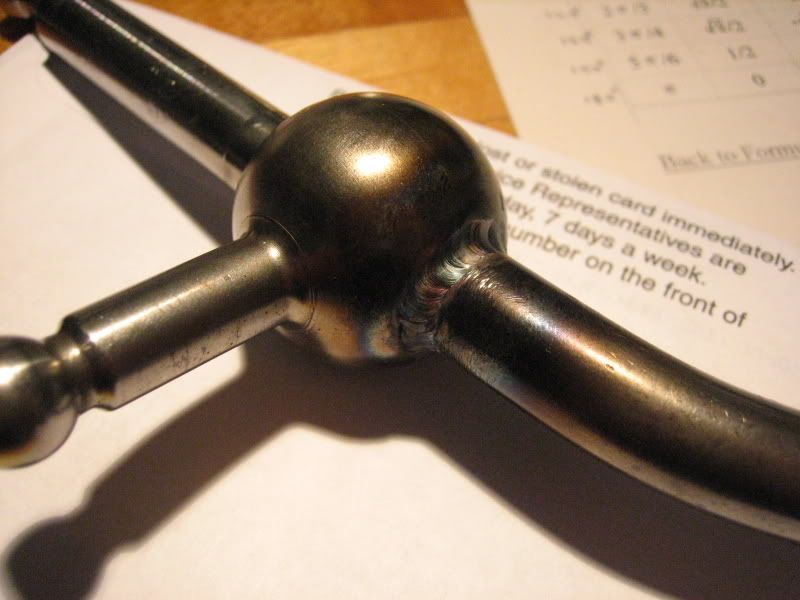

so here are some photos of the process thus far:

here's the bottom part, note the gouges from the edges of the vise. i had to smooth them out.  here's that pipe i talked about in the last post...it prevents said gouges...  using the punch to push the lower shaft down  here's the ball after pushing the shaft through a bit. sorry for the poor quality, but you can see the divot i drilled in the top of the shaft to guide the head of the punch.  here's a shot of the top part of the shaft, with the piece that i cut off. note the chamfer on the end so it fits back in the ball.  and lastly, these are a couple shots of the finished product, after i tig-welded it. if you're careful when you weld, you won't have to clean it up much for it to be smooth. i haven't smoothed this at all yet.

--------------------  do you know who i am, mr. worley? |

Oct 4, 2006 - 5:09 PM Oct 4, 2006 - 5:09 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

i decided i'm going to install it right now seeing as no-one appears to be keeping up on the thread.

see yall in a while with more pics! (take that, photobucket!) --------------------  do you know who i am, mr. worley? |

Oct 4, 2006 - 6:19 PM Oct 4, 2006 - 6:19 PM

|

|

|

Enthusiast  Joined Aug 28, '06 From U.S.A. Currently Offline Reputation: 2 (100%) |

in for pics. good job, i have no patience for all that. curious on how much clearance you'll have from the e-brake handle. anyone have a pic on clearance with a 7th gen ss?

|

Oct 4, 2006 - 6:43 PM Oct 4, 2006 - 6:43 PM

|

|

Enthusiast      Joined Jun 19, '05 From Nebraska Currently Offline Reputation: 4 (100%) |

nice weld job. But for the 35 bucks that i payed for my 7th gen, i dunno if the hassle of doing it yourself is worth saving a few pennies in this case. But bravo still for making it yourself!

-------------------- Teh Celica sleeps for Winter '06. Suspension overhaul begins........

|

Oct 4, 2006 - 9:47 PM Oct 4, 2006 - 9:47 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

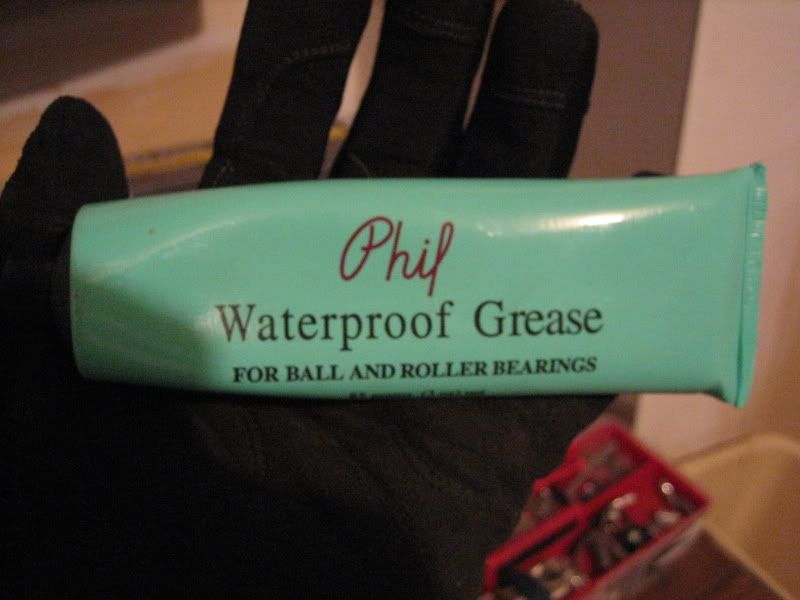

alright folks, here it is, the final installment. it took me a bit b/c i went out for some adult beverages in celebration of a jorb well done!

the requisite "before" picture.  the hacker, after a quick run-in with the wire wheel....  here's the new trick for removing those tough bolts at the front of the shifter assembly! (snake a combination wrench between the knee panel and the carpet)  a direct comparison.  this is how we remove the cups where i come from---a crescent wrench in the vise and a punch!  the finest multi-purpose lubricant in ZEE WORLD  a-a-a-and, we have a car again.  i'm in neutral there....in 1st and 2nd, i have about 1/2" clearance from the brake for my gorilla mitts. sideshot! (in 2nd gear) nice and stubby.  there you have it. one more trick! those two pesky phillips-head screws that hold the lower shroud around the shifter (which happen to be right next to the seat) are MUCH easier to get out with an 8mm combination wrench! all in all, i could have left it a little taller....but i did only pay 15 bucks for the shifter. if i'd used my own, this would have been free-ninety-nine. not bad, methinks! questions / comments welcomed! This post has been edited by uberschall: Oct 4, 2006 - 9:51 PM --------------------  do you know who i am, mr. worley? |

Oct 4, 2006 - 10:15 PM Oct 4, 2006 - 10:15 PM

|

|

|

Enthusiast      Joined Jul 27, '06 From Soda Currently Offline Reputation: 9 (91%) |

damn dude that's awesome. my poor lever. man how does it feel? when shifting and all? glad u had good use to it.

--------------------  |

Oct 4, 2006 - 10:29 PM Oct 4, 2006 - 10:29 PM

|

|

|

Enthusiast   Joined Jun 13, '06 From Omaha, Nebraska Currently Offline Reputation: 11 (100%) |

Nice lookin job uber, and awesome pics...I hate how to's with pics that don't make much sense...or maybe I'm just retarded and don't understand what I'm looking at

--------------------  We shall show mercy, but we shall not ask for it. |

Oct 4, 2006 - 11:22 PM Oct 4, 2006 - 11:22 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

QUOTE(block @ Oct 4, 2006 - 8:15 PM) [snapback]487783[/snapback] damn dude that's awesome. my poor lever. man how does it feel? when shifting and all? glad u had good use to it. ha, lets just say it has a new lease on life! it feels pretty snappy, which i like. it takes a bit more effort to shift, which has highlighted the 1st gear syncro issue i bought with the car, but it shouldn't be hard to get used to. it looks better, feels better...i'd say it's good so far. QUOTE(JonMarkos @ Oct 4, 2006 - 8:29 PM) [snapback]487787[/snapback] Nice lookin job uber, and awesome pics...I hate how to's with pics that don't make much sense...or maybe I'm just retarded and don't understand what I'm looking at thanks! i have a hard time with how-to's as well...that's why i opted for the forums instead...everything flows a little nicer! --------------------  do you know who i am, mr. worley? |

Oct 4, 2006 - 11:26 PM Oct 4, 2006 - 11:26 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

Nice job on the welds

--------------------  I will return one day. |

Oct 5, 2006 - 2:55 PM Oct 5, 2006 - 2:55 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

thanks, defgeph!

although i have to say it's mostly the $4000 welder i have access to at work. never underestimate the power of good equipment. --------------------  do you know who i am, mr. worley? |

Oct 7, 2006 - 11:12 AM Oct 7, 2006 - 11:12 AM

|

|

|

Enthusiast  Joined Aug 28, '06 From U.S.A. Currently Offline Reputation: 2 (100%) |

looks good. i might try it if i can find a spare shifter.

BTW, pics of you after adult beverages. |

Oct 20, 2006 - 6:34 PM Oct 20, 2006 - 6:34 PM

|

|

|

Enthusiast    Joined Jul 29, '03 From north of detroit Currently Offline Reputation: 6 (100%) |

UPDATE!!!

i have done some post-op work, in the form of installing 5mm washers under the left-side mounts. i thought the shifter sat a little too far to the left, and the washers have PERFECTED it. the problem, i believe, was that in spite of my best efforts to align it, i welded the arm a little cockeyed...or at least it looks that way compared to the stock lever in the picture above. needless to say, the moral of the story is: make sure the thing is dead-nuts! maybe i'll post some pictures later. --------------------  do you know who i am, mr. worley? |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: December 3rd, 2024 - 2:24 PM |