|

Sep 12, 2007 - 6:28 PM Sep 12, 2007 - 6:28 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

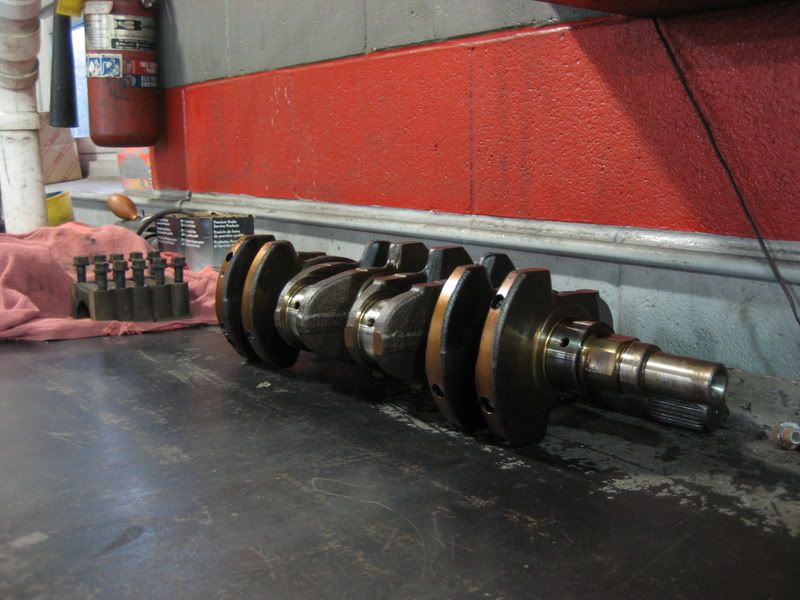

QUOTE(ILuvMyCelica95 @ Sep 12, 2007 - 10:49 AM) [snapback]595394[/snapback] Also- did they figure out why his was burning oil? yes. things that were wrong with the engine: 1. the oil control rings were just old and worn and got gummed up with oil so they sunk into the piston and since they didn't sit where they should oil just went right past them and got burned on the cylinder walls. the oil control rings...  sit in the bottom groove of the pistons...  and are held in place by another ring similar to the compression rings (shown below. they go in the two top grooves in the orientation shown) but are a little thinner  2. the thrust bearing was a little worn and had some play. this was just due to the added strain on the crank from it being attached to a manual transmission. the thrust bearing...  sits on either side of that middle seat in the grooves on either side  all the other bearings and seals were in pretty good shape, although I am still going to replace them all -------------------- |

Sep 12, 2007 - 7:02 PM Sep 12, 2007 - 7:02 PM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

awesome! thats a pretty big crank, i was surprised. very clean, esp the head.

you guys arent waisting any time either jeeze. -------------------- |

Sep 12, 2007 - 7:45 PM Sep 12, 2007 - 7:45 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

Thats awesome ! This is a project I have been wanting to do for years. I'm happy to have donated my engine to your cause

Keep the thread flowing like this. Its great to see what was the original problem, and what other parts started to fail because of it. Take pictures of the intake and exhaust posts on the head once you've cleaned them up. Also, take pics of the bottom of the head. Nice thread --------------------  I will return one day. |

Sep 12, 2007 - 8:25 PM Sep 12, 2007 - 8:25 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

im going to take a guess and say you used mobil1, jeff?

-------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 12, 2007 - 9:06 PM Sep 12, 2007 - 9:06 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

ON A 7A! Are you crazy ? Just used regular sludge for that engine.

--------------------  I will return one day. |

Sep 12, 2007 - 9:19 PM Sep 12, 2007 - 9:19 PM

|

|

Enthusiast    Joined Mar 28, '04 From St.Louis Currently Offline Reputation: 15 (100%) |

hey, this is very interesting for me cuse i am on the same route, how much NA power can u get out of a 7a. Well i really look forward to seeing pics of your progress. Hope all goes well. My two cents, if you have the money send the head of to Extrude Hone, its a process where they push an abrassive material through the entire head (Intake and Exhaust) and it polishes the sharp edges, increases flow and helps for breathing, the process costs $650 for our head, ive called them before to find out. Let me know if you need more info. Good luck

Matt --------------------  1994 GT Hatchback 1994 ST Coupe 1988 Corolla Wagon All-Trac 1999 Corvette 2008 Cobalt SS Turbo |

Sep 12, 2007 - 10:32 PM Sep 12, 2007 - 10:32 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

I can't wait to see how this turns out. Looks like fun.

-------------------- JDM guy made me do it.

|

Sep 12, 2007 - 11:29 PM Sep 12, 2007 - 11:29 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

QUOTE(Defgeph @ Sep 12, 2007 - 10:06 PM) [snapback]595593[/snapback] ON A 7A! Are you crazy ? Just used regular sludge for that engine. and it looks that good? crazy. guess all the oil brand debates just got thrown out the window. -------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 12, 2007 - 11:39 PM Sep 12, 2007 - 11:39 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

stef, i dont know how crazy you want to go with this build up, but if you are really planning to turbo, i would upgrade the pistons, rods, and headgasket, and do the cam regrinds, as well as replacing any rubber seal/gasket. then you would have a strong and nice flowing motor thats ready for the abuse of a turbocharger.

-------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 12, 2007 - 11:58 PM Sep 12, 2007 - 11:58 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(94celicadude @ Sep 12, 2007 - 10:19 PM) [snapback]595597[/snapback] hey, this is very interesting for me cuse i am on the same route, how much NA power can u get out of a 7a. Well i really look forward to seeing pics of your progress. Hope all goes well. My two cents, if you have the money send the head of to Extrude Hone, its a process where they push an abrassive material through the entire head (Intake and Exhaust) and it polishes the sharp edges, increases flow and helps for breathing, the process costs $650 for our head, ive called them before to find out. Let me know if you need more info. Good luck Matt wow... thats an insane price for that. we already did that this morning, took about 20 mins. I'll have pictures soon. I spoke to a friend of another tech about machining the head and it sounded like all he was going to do was clean it and make it look pretty and charge me $70. its not that dirty, we can clean it at work. if we have the right tools to port match the intake and exhaust we'll do that ourselves too. I can't imagine a 5 angle valve job being too precise either in which case we can probably do that too. we'll see how it goes -------------------- |

Sep 13, 2007 - 12:11 AM Sep 13, 2007 - 12:11 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

to find the size of the main bearings...

for the crankshaft...  there are 5 numbers engraved on the corner of the block (top and bottom)....  that correspond to 5 numbers engraved on the crankshaft itself...  you add the number on the crank to the corresponding number on the block. no number means 0. so the 01 on the crank pictured combines with the 2 printed on the block to come up with a #3 bearing. -------------------- |

Sep 13, 2007 - 2:54 AM Sep 13, 2007 - 2:54 AM

|

|

|

Enthusiast  Joined Apr 16, '06 From Melbourne, Australia Currently Offline Reputation: 0 (0%) |

that's looks amazing, makes we wonder why i didn't pick up to being a mechanic, regretting it now, but that's looks awesome

--------------------  |

Sep 13, 2007 - 6:08 PM Sep 13, 2007 - 6:08 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

I cleaned and painted the block yesterday...

and we honed the cylinders. I don't have a picture of the tool we used but it looks like a bunch of wire bristles with balls on the end attached to a drill. you have to break the glaze on the cylinder walls in a crosshatch kind of pattern so the oil sticks better...  and today we just re-ringed the pistons..  there are two thin rings that go above and below the oil control rings in the bottom groove and the top two are the compression rings. you want to place the openings in the rings on alternating sides and always right above the wrist pin since that takes the least stress. so in the picture the opening in the ring under the oil control ring is facing back, the one on top is facing forward, the first compression ring facing back (there is a "2R" written on it that should be facing up), and the top ring facing front. they fit very loose like that so as to make a tighter seal with the cylinder wall when installed.  we can't do much else until the main bearings come in (probably Monday) since we need them to put the bottom end back together. we want to finish the bottom completely before starting on the head, just to keep things organized. This post has been edited by hurley97: Sep 13, 2007 - 6:10 PM -------------------- |

Sep 13, 2007 - 6:22 PM Sep 13, 2007 - 6:22 PM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

if your not gonna get the pauters and want a little extra strength id shotpeen the rods while they are out. its cheap and it gives a little bit of strength to them

-------------------- -Brian

|

Sep 13, 2007 - 6:26 PM Sep 13, 2007 - 6:26 PM

|

|

|

Enthusiast      Joined Jan 28, '05 From Redondo Beach, CA Currently Offline Reputation: 86 (100%) |

reminds me of rebuilding a cummins engine, same process but cummins is like 10x bigger!

--------------------  |

Sep 13, 2007 - 7:19 PM Sep 13, 2007 - 7:19 PM

|

|

Enthusiast      Joined Jul 7, '06 From Los Alamos, NM Currently Offline Reputation: 1 (100%) |

this has to be the most interesting thread ever!

keep up the good work! -------------------- 2015 Subaru WRX. World Rally Blue/Black

2001 Honda S2000. Spa Yellow/Black |

Sep 13, 2007 - 7:34 PM Sep 13, 2007 - 7:34 PM

|

|

|

Enthusiast      Joined Jul 7, '03 Currently Offline Reputation: 55 (100%) |

I personally would check all parts with a micrometer and

make sure crank, rods, oil pump meet all specs. Thats kinda my thing though. looks a little scuffed at least in the one pic. -------------------- JDM guy made me do it.

|

Sep 13, 2007 - 9:26 PM Sep 13, 2007 - 9:26 PM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

Steff this thread is awesome! keep it up

|

Sep 14, 2007 - 9:02 AM Sep 14, 2007 - 9:02 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(lagos @ Sep 13, 2007 - 12:39 AM) [snapback]595641[/snapback] stef, i dont know how crazy you want to go with this build up, but if you are really planning to turbo, i would upgrade the pistons, rods, and headgasket, and do the cam regrinds, as well as replacing any rubber seal/gasket. then you would have a strong and nice flowing motor thats ready for the abuse of a turbocharger. from what I hear the pistons and rods will more than stand up to the abuse of a turbo (I'll save that for when I rebuild the engine thats in my car since it'll be much worse and probably need a re-bore anyway), the head gasket is already metal, I will be replacing any and all seals/ bearings I possbily can, this is going to be like a brand new engine when it goes in, I do want to smooth out the head some to make it flow better, right now I'm thinking about the bigger cams. WebCams has done a grind for the 7A before and it would cost about $575 and about 3 weeks. Reasons I'm not sure about them right now is 1, they cost more than the rebuild parts 2, I'm not sure if I want this engine to sit at work for another couple weeks and 3, I really don't know how they will affect the car since they tell me it has only been done twice before. Also, what I kind of want to do is dyno the stock re-built 7A, then with just the cams, then the turbo. still thinking about it... -------------------- |

Sep 14, 2007 - 9:12 AM Sep 14, 2007 - 9:12 AM

|

|

Enthusiast      Joined Dec 16, '02 From New York Currently Offline Reputation: 4 (100%) |

Steff i love this i feel like im in class

I wish i had someone around to learn off of, this is a GREAT opportunity. -------------------- Buy my Celica $2,500 - http://www.6gc.net/forums/index.php?showtopic=76562&st=0

|

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 23rd, 2024 - 7:30 PM |