|

Sep 14, 2007 - 9:13 AM Sep 14, 2007 - 9:13 AM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

4ag(z)e head gaskets will work also (i do believE)

|

Sep 14, 2007 - 10:13 AM Sep 14, 2007 - 10:13 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

yes you probably could but the 7A headgasket is metal so I can just use that

-------------------- |

Sep 14, 2007 - 11:10 AM Sep 14, 2007 - 11:10 AM

|

|

|

Enthusiast      Joined Oct 13, '02 From Blairstown, New Jersey Currently Offline Reputation: 6 (100%) |

Stef, good to see that you're on your way with the project.

I think a pretty modest increase in the I/E duration of the camshafts wouldn't be a bad idea, as long as its not so agressive that it affects the off-boost performance alot. Maybe keep the same proportion as the stock camshafts, just increase their duration slightly to allow more compressed air in, more exhaust gasses out per cycle but with good drivability? Between a rebuilt and ported top-end, camshafts, and perhaps using some uprated 4AGE/4AGZE valve springs with the proper shims to prevent any float from the reworked head when it sees boost, you would have an awesome setup. Looks great so far Stef, I don't think you're going to need alot of our advice with the build. It looks like you have the best help you can get with the rebuild and you already have a solid start on the bottom end. Best of luck, I'll see you on the dark side...of boost. -------------------- 3rd gen ST205 3SGTE - Alive and boosting. |

Sep 14, 2007 - 12:09 PM Sep 14, 2007 - 12:09 PM

|

|

|

Enthusiast Joined Jun 29, '07 From Fall River, MA Currently Offline Reputation: 0 (0%) |

QUOTE Between a rebuilt and ported top-end, camshafts, and perhaps using some uprated 4AGE/4AGZE valve springs with the proper shims to prevent any float from the reworked head when it sees boost, you would have an awesome setup that would also allow you to rev a bit higher as well, as long as the stock rod bolts can take it. whoops manny posting as brennton on moms puter...lol --------------------  |

Sep 16, 2007 - 4:03 AM Sep 16, 2007 - 4:03 AM

|

|

|

Enthusiast      Joined Oct 13, '02 From Blairstown, New Jersey Currently Offline Reputation: 6 (100%) |

QUOTE as long as the stock rod bolts can take it. Haha. Lets put it to the test! -------------------- 3rd gen ST205 3SGTE - Alive and boosting. |

Sep 17, 2007 - 9:39 AM Sep 17, 2007 - 9:39 AM

|

|

|

Enthusiast  Joined Nov 29, '06 From Newnan, Ga. Currently Offline Reputation: 3 (100%) |

Nice pics!

|

Sep 17, 2007 - 11:30 AM Sep 17, 2007 - 11:30 AM

|

|

Enthusiast   Joined Dec 12, '06 From Fob Sharana, Afghanistan Currently Offline Reputation: 2 (100%) |

QUOTE(Silver94CelicaOwner @ Sep 16, 2007 - 5:03 AM) [snapback]596416[/snapback] QUOTE as long as the stock rod bolts can take it. Haha. Lets put it to the test! I always thought the stock rods on a 7A were weaker but has a bigger stroke. |

Sep 19, 2007 - 6:51 PM Sep 19, 2007 - 6:51 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

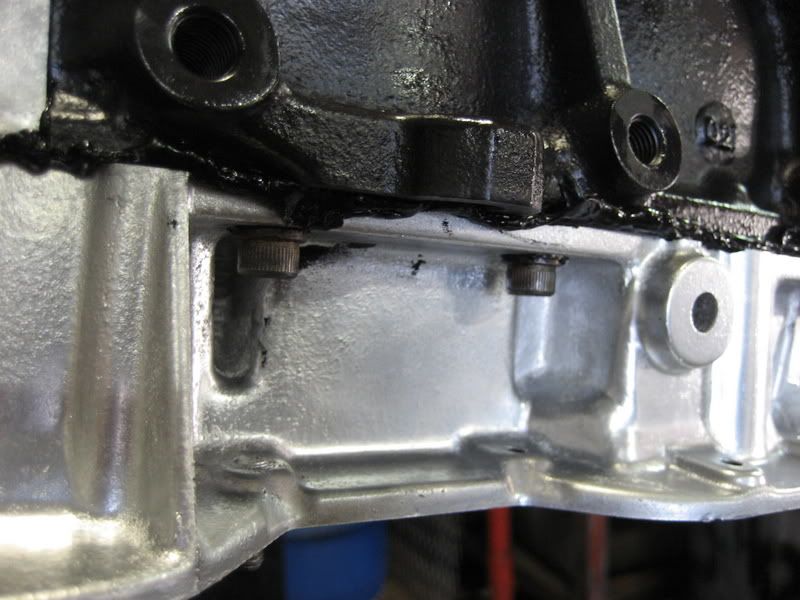

QUOTE(Silver94CelicaOwner @ Sep 16, 2007 - 5:03 AM) [snapback]596416[/snapback] QUOTE as long as the stock rod bolts can take it. Haha. Lets put it to the test! oh you know I will Corey Finally! the main bearings came in and we got back to work... There are two sides to each main bearing, one is smooth and the other has a groove and a hole in it. remember these bearings corresponded to the number ont he crankshaft + the number on the block, I had four #3 bearings and one number 2, so here you have to make sure you put the bearings where they belong. the smooth half goes on the caps that hold the crankshaft in, there are little notches in the bearing that match up with a notch on the cap, you can see them on the two caps all the way to the right in the pic...  the other side of the bearing goes on the block itself and lines up with the journal hole and the same kind of notch as on the cap...  the middle bearing seat also contains the thrust washers. there are four of them in the set, two with little tabs and two without. there are also two side to each of them, one side is smooth and the other has some sort of material on it (sort of like a brake pad). the two without the tabs go on the block, we put some vasaline on the smooth side and stuck it to the indentations provided with the material side facing outward...  the two with the tabs go on the cap in the same orientation, vasaline on it and smooth side in...  then we oiled up all the bearings and placed the crankshaft back in place.  then oiled up the bearings on the caps and put some oil on the bolt threads as well before putting the caps on and torquing them down to 44 ft/lbs next was the rear main seal and the crankshaft seal. hammered the seals flush with the housing, put some FIPG (Form In Place Gasket) on each side of the regular gasket, lubed up the inner part of each seal, then put them in place and bolted them in.  And that was it for today. Pistons and top part of the oil pan are going in tomorrow morning and that will pretty much be all for the bottom end. -------------------- |

Sep 19, 2007 - 9:16 PM Sep 19, 2007 - 9:16 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

-------------------- |

Sep 19, 2007 - 9:55 PM Sep 19, 2007 - 9:55 PM

|

|

Enthusiast      Joined Feb 7, '03 From Northern Virginia Currently Offline Reputation: 23 (100%) |

wow are you keeping all the receipts and costs tallied? i want to know how much it is as i have a 7a in my garage that needs some tlc

nice job so far btw |

Sep 19, 2007 - 11:47 PM Sep 19, 2007 - 11:47 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

Looking good.

--------------------  I will return one day. |

Sep 19, 2007 - 11:54 PM Sep 19, 2007 - 11:54 PM

|

|

Administrator      Joined Aug 23, '02 From Seattle, WA Currently Offline Reputation: 14 (100%) |

Looks great. I love threads like this.

-------------------- New Toyota project coming soon...

|

Sep 19, 2007 - 11:59 PM Sep 19, 2007 - 11:59 PM

|

|

Enthusiast      Joined Jul 7, '06 From Los Alamos, NM Currently Offline Reputation: 1 (100%) |

QUOTE(Coomer @ Sep 19, 2007 - 11:54 PM) [snapback]597505[/snapback] Looks great. I love threads like this. X infiniti wow this truely is the most interesting thing right now! -------------------- 2015 Subaru WRX. World Rally Blue/Black

2001 Honda S2000. Spa Yellow/Black |

Sep 23, 2007 - 8:05 PM Sep 23, 2007 - 8:05 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

sorry for the delay on the progress report... that CSP meet was kind of crazy...

now for putting the pistons in... the rod bearings come in sets of 2 and both sides are the same  on the pistn rod itself there is a hole that matches up with the hole in the bearing, and just like the main bearings there is the little notch that matched up as well...  on the cap end there is not holes so you just use the little notch to place it in the right orientation...  then oil up both sides of the bearings  now if you remember from before the compression and oil control rings stick out a lot  so you need to use a ring compressor to push them in, the pistons need to be dunked in oil before this step...  now at this point you want to put in two pistons at a time (either 1 & 4 or 2 & 3) and you are going to want to push them all the way down so make sure the part of the crank the rod sits on is all the way down and straight. then we cleaned off the cylinder walls a little in case anything had gotten in there from it sitting for a while. double check to make sure the right piston is going into the right cylinder using the stamped numbers on them...  so with the ring comrpessor still on the piston you place the rod end into the cylinder and use the end of a hammer or something to gently tap the piston down into place. once its out of the ring compressor you put that aside and finish tapping it down while you kind of guide the rod end onto the crankshaft  the caps are held on by stretch bolts that need to be torqued to 44 ft/lbs then tightened another 90 degrees. so once they are torqued you mark them so you know where to stop after doing the 90 degree turn...  the cast part of the oil pan is easy, put a crap load of FIPG on and tap it a little with a hammer so it sits properly. there are a bunch of allen head bolts and some normal ones that go on the inside  put the little gear and the crank postion sensor back on...  and thats how it sits right now..

-------------------- |

Sep 23, 2007 - 8:13 PM Sep 23, 2007 - 8:13 PM

|

|

|

Enthusiast     Joined Jan 18, '07 From Bergen county NJ Currently Offline Reputation: 24 (100%) |

Looking good, nice work.....you impress me

-------------------- |

Sep 23, 2007 - 8:26 PM Sep 23, 2007 - 8:26 PM

|

|

|

Enthusiast      Joined Mar 22, '07 From Houston, TX Currently Offline Reputation: 4 (100%) |

wow. this thread amazes me.

rebuilding doesn't seem too hard now.. -------------------- QUOTE "And, as always, your friendship, help, and dedication to the advancement of Texas Celica dominance is GREATLY appreciated. Thanks bro." -DEATH 1994 GT: V6 swap, 5speed E53 W/ LSD, All Power, now RED 1995 ST: SOLD @273k miles, Auto, all power, CarPC, White 1994 ST: Totaled, 5spd, all power, Red RIP 07/09/09 @ 241,810 1994 Lexus LS400: This is my new DD |

Sep 23, 2007 - 9:19 PM Sep 23, 2007 - 9:19 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

very nice progess.

|

Sep 23, 2007 - 9:40 PM Sep 23, 2007 - 9:40 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

HOT! not trying to be an internet mechanic here, but why aren't you using assembly lube? motor oil is ok for most stuff, but i would worry that most of it will just drip down into the pan, an you'll have little protection the first time you crank it up. This post has been edited by lagos: Sep 23, 2007 - 9:40 PM -------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Sep 23, 2007 - 9:48 PM Sep 23, 2007 - 9:48 PM

|

|

|

Enthusiast      Joined Jan 28, '05 From Redondo Beach, CA Currently Offline Reputation: 86 (100%) |

for deisels we use gear oil to lube the bearings

--------------------  |

Sep 23, 2007 - 9:57 PM Sep 23, 2007 - 9:57 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

motor oil works fine for putting pistons in, its what myself and most other people i know normally use.

|

|

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 23rd, 2024 - 7:59 PM |