|

Sep 24, 2007 - 9:23 AM Sep 24, 2007 - 9:23 AM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

This is amazing steff, keep it up! I'm sure you will be getting phone calls when i start tearing down the 3s

|

Sep 24, 2007 - 9:43 AM Sep 24, 2007 - 9:43 AM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

QUOTE(hurley97 @ Sep 23, 2007 - 8:05 PM) [snapback]598432[/snapback] double check to make sure the right piston is going into the right cylinder using the stamped numbers on them...  -------------------- -Brian

|

Sep 24, 2007 - 9:47 AM Sep 24, 2007 - 9:47 AM

|

|

Enthusiast      Joined Apr 20, '06 From Florida Currently Offline Reputation: 44 (100%) |

is that a 3 stamped sideways in the middle of the two 2's?

|

Sep 24, 2007 - 11:14 AM Sep 24, 2007 - 11:14 AM

|

|

|

Enthusiast     Joined Aug 23, '05 From Princeton, Minnesota Currently Offline Reputation: 7 (100%) |

QUOTE(jcbass7 @ Sep 24, 2007 - 9:47 AM) [snapback]598575[/snapback] is that a 3 stamped sideways in the middle of the two 2's? It's an M i have 2 rods that have an M and 2 rods that have a U -------------------- -Brian

|

Sep 24, 2007 - 12:40 PM Sep 24, 2007 - 12:40 PM

|

|

|

Enthusiast  Joined Nov 29, '06 From Newnan, Ga. Currently Offline Reputation: 3 (100%) |

They look like match marks to me, so you don't mix up the rods and rod caps. The rods can go in any hole position when assembling.

This post has been edited by 56willysnut: Sep 24, 2007 - 12:41 PM |

Sep 24, 2007 - 4:54 PM Sep 24, 2007 - 4:54 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(Celiracer18 @ Sep 24, 2007 - 10:43 AM) [snapback]598573[/snapback] QUOTE(hurley97 @ Sep 23, 2007 - 8:05 PM) [snapback]598432[/snapback] double check to make sure the right piston is going into the right cylinder using the stamped numbers on them... sorry, I thought I explained it before but I can't find it so I guess I didn't... when you take the pistons out there will be a number already stamped on them, that lets you know the size of the piston. so on the block there is the set of 5 numbers that pair with the main bearings and on the opposite end a set of 4 numbers that tell the cylinder bore size. so a number 2 on the piston rod would go to a number 2 bore, I had three #2's and one #3. but unless you are getting new pistons you want to make sure the piston you take out of cylinder 1 goes back into cylinder 1, so as you take them out one by one you want to label them somehow, we stamped the number on the blank side (in a different orientation so we could tell the difference) and yes, the 'M' is a match line -------------------- |

Sep 26, 2007 - 7:02 PM Sep 26, 2007 - 7:02 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

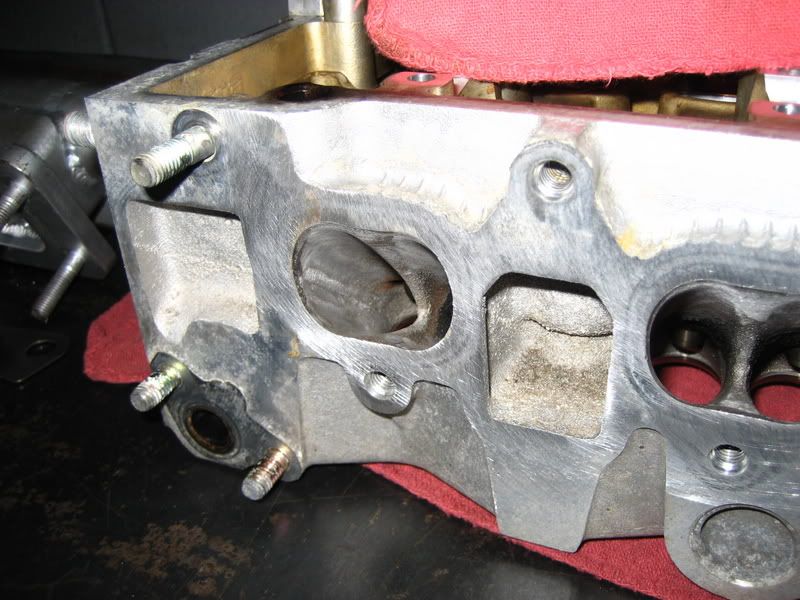

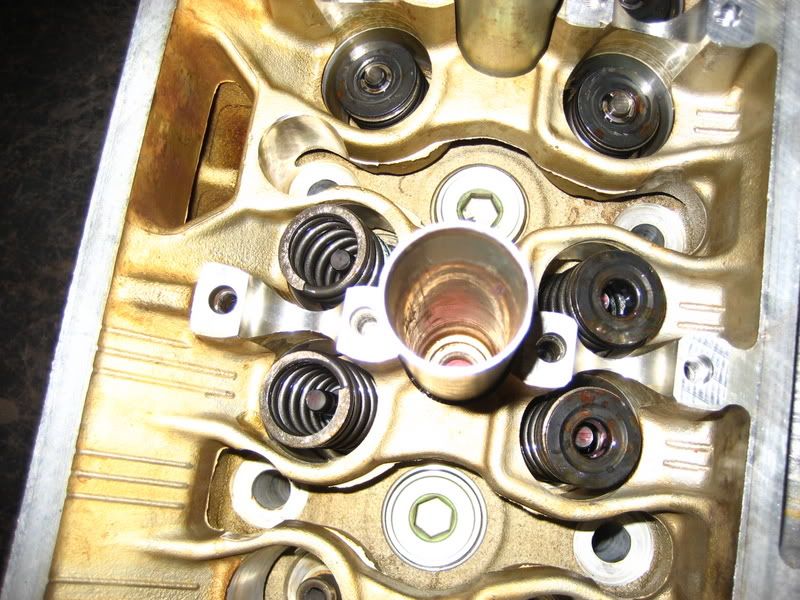

now the fun part... the top end

we started by taking the intake manifold and fuel rail off and stripping the head of everything else (i.e. EGR, brackets, sensors, valve shims) at that point to get the valve springs out you have to dislodge the keepers from their seat, there is a special tool for that but we did it a different way. tools include a hollow tube about 1/2" in diameter with a handle on it and a hammer. you just have to place the tube onto the top of the spring seat and hit the top of it pretty hard until the two little keepers come out and the spring pops up...  (beware of doing this in the car since its really easy for the tiny keepers to pop out and into one of the oil return holes) here you can see all the springs, seats, keepers, and the little washers under the springs  close up of the spring and seat...  the keepers are extremely small... I can't wait to see how we get them back in...  now the valve seals. there is a special tool for them, just grab and pull... really hard  some of the rubber from the valve seals stayed there and need to be cleaned off so the new ones snap into place properly...  at that point the valves slide right out the bottom. they have to stay in order since they have already seated to the head and if you move them they may not seal properly.  I used a wire wheel to clean the crap off the valves... that was very time consuming    -------------------- |

Sep 26, 2007 - 8:02 PM Sep 26, 2007 - 8:02 PM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

going to cut the valves and seats and then lap them?

-------------------- |

Sep 27, 2007 - 10:26 PM Sep 27, 2007 - 10:26 PM

|

|

Moderator      Joined Apr 17, '03 From Rockland NY Currently Offline Reputation: 15 (100%) |

So awesome. Keep it up Steff

--------------------  I will return one day. |

Sep 27, 2007 - 11:04 PM Sep 27, 2007 - 11:04 PM

|

|

|

Enthusiast     Joined Jul 4, '07 From US Currently Offline Reputation: 2 (100%) |

women with tools are hot ^^ there is no way of saying it a different way

|

Sep 28, 2007 - 10:38 AM Sep 28, 2007 - 10:38 AM

|

|

Enthusiast      Joined Dec 16, '02 From New York Currently Offline Reputation: 4 (100%) |

i think when this is all said and done this should be a sticky it's awesome

-------------------- Buy my Celica $2,500 - http://www.6gc.net/forums/index.php?showtopic=76562&st=0

|

Sep 28, 2007 - 10:50 AM Sep 28, 2007 - 10:50 AM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

QUOTE(Bitter @ Sep 26, 2007 - 9:02 PM) [snapback]599404[/snapback] going to cut the valves and seats and then lap them? no. I decided anything I could do to it at this point would cost a lot for very little to almost no gain. we 'ported and polished' the intake and exhaust ports as best we could and I'm pretty happy with the results. all the overkill things (boreing out the cylinders, bigger pistons, valve jobs, etc) will be done to the engine that is still in my car since it will probably be bad enough to need the extensive work, plus I'll have a lot more time before the rebuilt one needs replacing so I won't have to spend all the money at one time. This rebuilt engine probably will not be actually going into the car for a few months. I want my current engine to make it to 200k before I replace it... 8000 miles to go, so probably 5-6 months. so with that kind of time on my hand now the debate is do I want to get all the turbo stuff and put it on the engine while its out of the car then just drop in the rebuilt motor and turbo setup at once, or do I want to run the stock rebuilt 7A for a while then turbo it ? I think I'm leaning towards doing the turbo setup outside the car... thoughts ? we did put the valves back in already, I do have more pictures but I'll let you guys look those last ones over first -------------------- |

Sep 28, 2007 - 10:58 AM Sep 28, 2007 - 10:58 AM

|

|

Enthusiast      Joined Nov 12, '02 From Webster Ma. Currently Offline Reputation: 1 (100%) |

outside the car turbo setup is a great idea! heck you could even produce a JDM guy turbo kit ;P

-------------------- |

Sep 28, 2007 - 11:03 AM Sep 28, 2007 - 11:03 AM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

so basically you are rebuilding this motor,

putting it in, and taking the current one out. then you are going to strip/rebuild/upgrade the motor you pull out? i'm not sure if i get the concept behind that cause having to build two motors instead of one? and doing things twice? is going to just be tossing money if this motor(the currently being rebuilt) is coming back out of the car for the motor (currently in car but going to be built?) is just going back in? why not just leave the one in there till you finish really building the one you are now, then swap them 1 time and call it done? maybe i'm miss understanding what you are doing? This post has been edited by playr158: Sep 28, 2007 - 11:04 AM |

Sep 28, 2007 - 11:36 AM Sep 28, 2007 - 11:36 AM

|

|

|

Enthusiast      Joined Jun 13, '05 From Poughkeepsie, NY Currently Offline Reputation: 2 (100%) |

U missed the point dan.

shes rebuilding this one, while she runs her current one up to 200k miles. When that happens (8ish or so months) she is gonna drop the rebuilt motor into her car. (turbo or not) got it? Steff, if your gonna rebuild the motor, and u have 8 months to do so....build up the motor, turbo it, and put down like 200whp on the 7a. You work at toyota, i bet you can find some kinda deal in 4agze Forged pistons. --------------------  Kawi Love |

Sep 28, 2007 - 12:52 PM Sep 28, 2007 - 12:52 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

QUOTE(devilsden97 @ Sep 28, 2007 - 12:36 PM) [snapback]599855[/snapback] U missed the point dan. shes rebuilding this one, while she runs her current one up to 200k miles. When that happens (8ish or so months) she is gonna drop the rebuilt motor into her car. (turbo or not) got it? I got that much read my post.. my point of getting lost is the use of the motor that is going to 200k? "all the overkill things (boreing out the cylinders, bigger pistons, valve jobs, etc) will be done to the engine that is still in my car since it will probably be bad enough to need the extensive work, plus I'll have a lot more time before the rebuilt one needs replacing so I won't have to spend all the money at one time." ^all that is happening to the motor with 200k? i don't see why she is putting the effort into this one just to use it for a little bit while building the 200k then switching it back. saving time/money cause things will be done 2 times and motors swapped 2 times This post has been edited by playr158: Sep 28, 2007 - 12:53 PM |

Sep 28, 2007 - 1:22 PM Sep 28, 2007 - 1:22 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

I plan on keeping the car for a long time. the motor coming out of my car will be my backup, I'm planning to beat the crap out if the rebuilt turbo 7A. and the fact that it will be pretty much all stock inside I'm not sure how long it will last.

I'm not rebuilding this one just to keep it for a little while, I'm going to use the rebuilt one until it starts getting tired again. -------------------- |

Sep 28, 2007 - 1:34 PM Sep 28, 2007 - 1:34 PM

|

|

|

Enthusiast      Joined May 22, '03 From NOVA Currently Offline Reputation: 16 (100%) |

ah word gotcha cool beans!

|

Sep 29, 2007 - 8:55 PM Sep 29, 2007 - 8:55 PM

|

|

|

Enthusiast      Joined Mar 3, '04 From Portsmouth, RI Currently Offline Reputation: 33 (100%) |

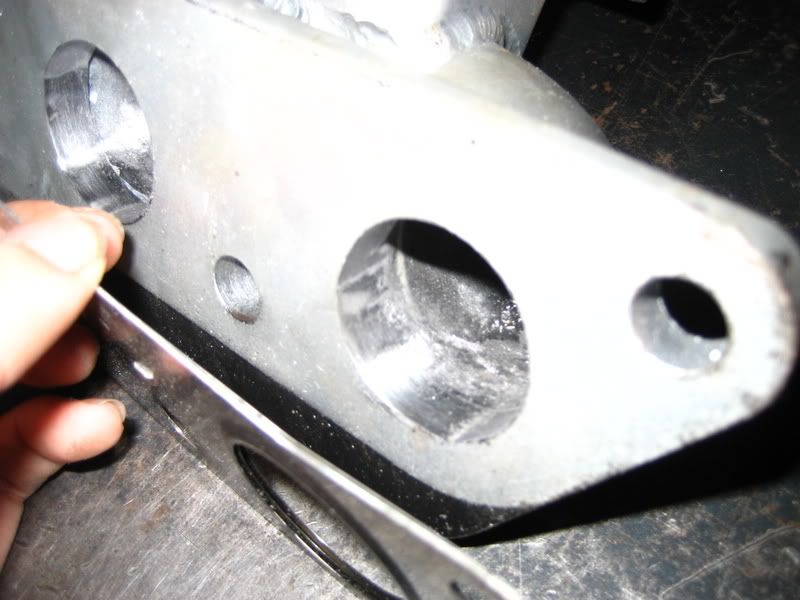

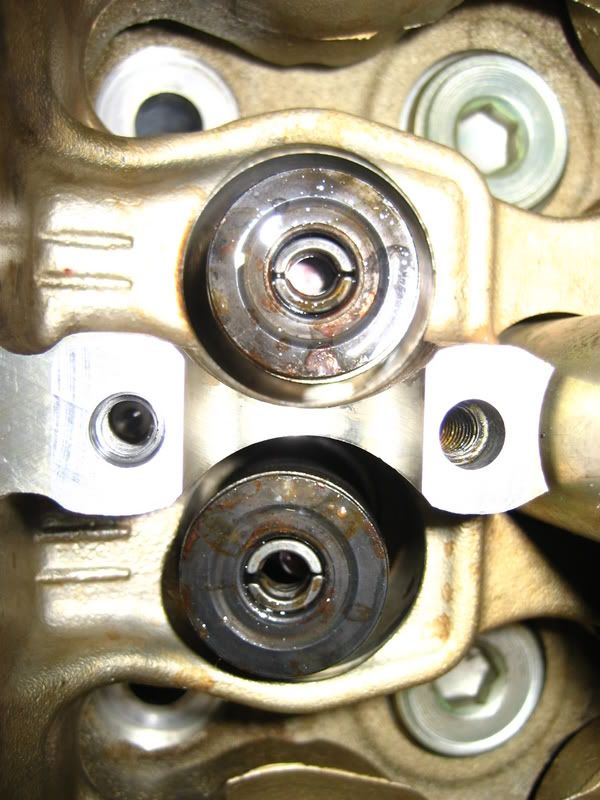

we cleaned up block and ground out the intake and exhaust ports a little...

also gasket matched the turbo manifold I bought  now to putting the valves back in. making sure to keep them in order, we did one cylinder at a time (2 intake and 2 exhaust valves) everything (washers, valves, springs, keepers, seats, etc) were soaked in oil before doing all this...  (in the pic its only half cleaned up) then placed the valve seals onto the top of the valves  then using a deep 10mm 12pt socket and extension pushed them down until you feel them almost 'snap' into place  now is the time to place the little washer in place in order to seat the valve springs and the top seat of the spring  heres the part you would have to be very careful with if you were to do this in the car. you have to hand place those tiny keepers into the top seats of the valve springs  there is a special tool for this part but I didn't get a picture of it. I'll get a pic of it if anybody really wants to know what it looks like. pushing the springs back down is the pain in the arse part of this, sometimes the keepers snap right onto the top of the valve and sometimes they don't and you have to take them back out and try again. the tech that's doing this with me likes to tap them gently with a little hammer after this part just to make sure they've seated properly.  thats all for now. just more cleaning and putting back together. its like 90% done -------------------- |

Sep 30, 2007 - 7:09 AM Sep 30, 2007 - 7:09 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

that is totally bad a$$ steff. now we need to send you a 5s, and you can say you know how to rebuild BOTH!!!

gaha great work, keep it up! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 23rd, 2024 - 9:23 PM |