|

Jun 19, 2008 - 1:32 AM Jun 19, 2008 - 1:32 AM

|

|

|

Enthusiast    Joined Jul 31, '05 From Southern California Currently Offline Reputation: 7 (100%) |

I had a some difficulty in finding this information before strangely enough locating it on the autozone page for the 7A-FE corolla.

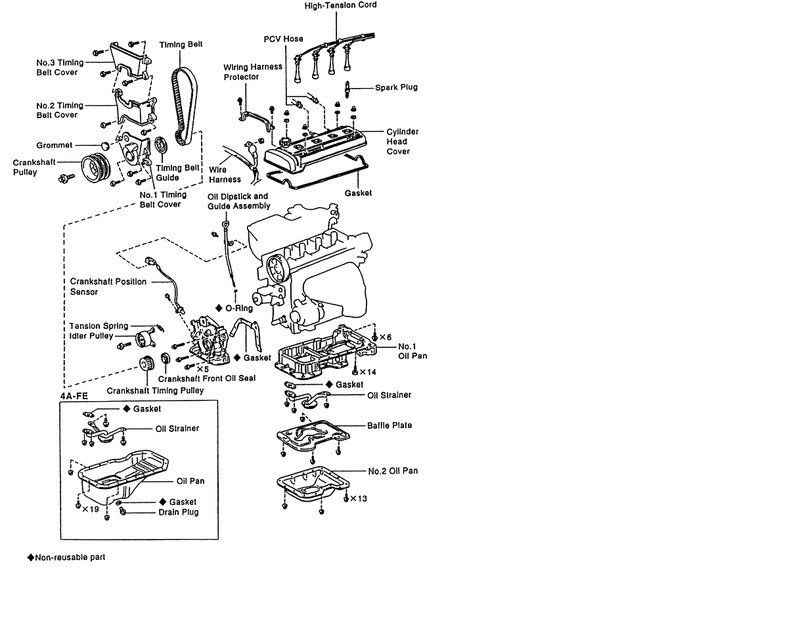

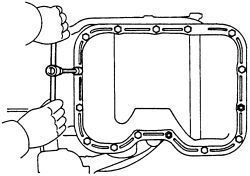

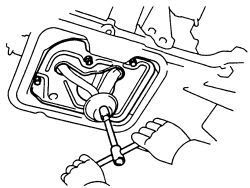

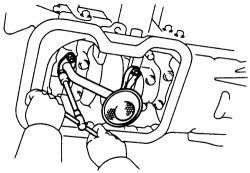

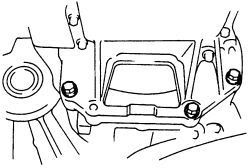

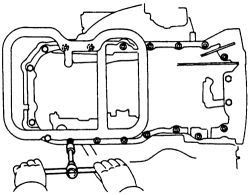

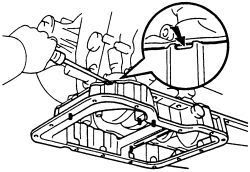

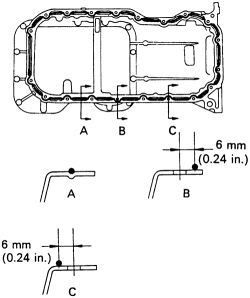

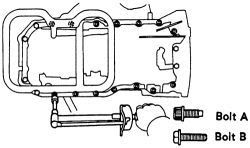

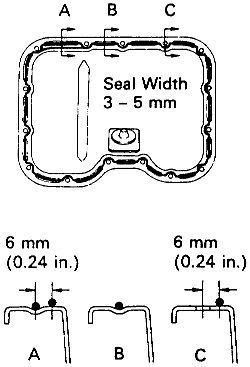

I thought that this information could prove useful to anyone else that would need to change out their oil pan on the 7A-FE. I am posting this here so that in the likelyhood that autozone changes their website and the information is no longer available it will remain in our community at least. Original Website Write Up First an Exploded View  Oil Pan Removal 7A-FE Engine On the 1993-97 7A-FE engine, a 2 piece oil pan assembly is used. The No. 1 oil pan (upper) is made of aluminum and the No. 2 oil pan (lower) is made of steel. The upper oil pan section is secured to the cylinder block and the transaxle housing, increasing rigidity. Removal 1. Disconnect the negative battery cable. 2. Raise and safely support the vehicle. 3. Drain the engine oil in a suitable container. 4. Place a jack under the transaxle to support it. 5. Remove the splash shield from under the engine. 6. Raise the jack under the transaxle slightly. 7. Disconnect the oxygen sensor wiring at the front pipe. Remove the bolts retaining the front pipe to the mounting bracket. Unbolt the support bracket holding the pipe to the catalyst. Remove the nuts and lower the pipe from the engine. 8. Remove the 13 bolts and 2 nuts retaining the No. 2 oil pan. Insert a blade between the pan and the baffle plate. Carefully pry the pan off.  Fig. 9: Unbolt and lower the No. 2 oil pan-7A-FE engine 9. To remove the upper (No. 1) oil pan continue. 10. Remove the bolts and nuts retaining the baffle plate.  Fig. 10: Remove the 2 bolts, nuts and lower the baffle plate from the upper oil pan-7A-FE engine 11. Remove the oil strainer and gasket. Discard the old gasket.  Fig. 11: Remove the oil strainer to access the upper oil pan-7A-FE engine 12. Remove the 3 transaxle mounting bolts from the engine rear end plate side. Remove the 6 bolts, then using a 5mm hexagon wrench, remove the 14 bolts securing the No. 1 oil pan. Insert a pry tool between the pan and block and carefully separate the pan from the engine.  Fig. 12: Unbolt and remove the transaxle mounting from the engine rear end plate side-7A-FE engine  Fig. 13: Unbolt the upper (No. 1) oil pan ...  Fig. 14: ... and pry between the block and pan to remove-7A-FE engine To install: Be careful not to drop any oil on the contact surfaces of the pan and block. 13. Using a razor blade and gasket scraper, remove all traces of packing (FIPG) material from the gasket surfaces. Thoroughly clean all mating surfaces to remove loose material. Clean both sealing surfaces with non-residue solvent.  Fig. 15: Apply a reasonable amount of sealant (FIPG) to the No. 1 oil pan surface-7A-FE engine 14. Apply new packing (FIPG) 08826-00080 to the No. 1 oil pan as shown. Avoid apply excessive amounts to the surface. Be especially careful around the oil passages. Parts must be assembled within 3 mins of application. Otherwise, the sealer (FIPG) must be removed and reapplied. 15. Using a 5mm hexagon wrench, install the No. 1 oil pan with 14 NEW bolts. Tighten the bolts (A) to 12 ft. lbs. (16 Nm). Install the 6 bolts (B), and tighten them to 69 inch lbs. (8 Nm). 16. Install and tighten the 3 transaxle mounting bolts to the engine rear end plate side and tighten them to 17 ft. lbs. (23 Nm). 17. Place a new gasket on the oil strainer and tighten the retaining nuts to 82 inch lbs. (9 Nm). 18. Attach the oil pan baffle and tighten the mounting bolts and nuts to 69 inch lbs. (8 Nm). 19. Using a razor blade and gasket scraper, remove all traces of packing (FIPG) material from the gasket surfaces. Thoroughly clean all mating surfaces to remove loose material. Clean both sealing surfaces with non-residue solvent.  Fig. 16: Tighten the No. 1 oil pan bolts to the correct torque-7A-FE engine 20. Apply new packing (FIPG) 08826-00080 to the No. 2 oil pan as shown. Avoid apply excessive amounts to the surface. Be especially careful around the oil passages.  Fig. 17: Apply FIPG to the No. 2 oil pan as shown-7A-FE engine Parts must be assembled within 3 minutes of application. Otherwise, the sealer (FIPG) must be removed and reapplied. 21. Attach the No. 2 oil pan and tighten the 13 bolts and 2 nuts to 43 inch lbs. (5 Nm). 22. Using new gaskets, attach the front exhaust pipe to the manifold and catalyst. 23. Lower the jack from the transaxle. 24. Lower the vehicle, and fill the crankcase with the appropriate amount of engine oil. Refer to the Capacities chart. 25. Connect the negative battery cable, start the engine and check for leaks. If all is well, raise the vehicle slightly and install the engine under cover. 26. Recheck the engine oil level, and top off if necessary. |

Jun 19, 2008 - 7:03 PM Jun 19, 2008 - 7:03 PM

|

|

Enthusiast      Joined Oct 30, '04 From So Cal Currently Offline Reputation: 13 (100%) |

Awesome! I might have to change oil pan soon. I banged it on speed bumps a couple times :-O

-------------------- |

Feb 18, 2016 - 9:12 PM Feb 18, 2016 - 9:12 PM

|

|

Enthusiast     Joined Jul 19, '04 From Los Angeles, CA Currently Offline Reputation: 2 (100%) |

Hey this is great, but I'm confused about if I should use a cork gasket or not. I just purchased a new oil pan and cork gasket, but most instructions I find show only using gasket maker. Would it be overkill to use both? Or could I just use the court one?Also, does it need to be Toyota brand gasket maker or can it just be any high temp generic gasket maker?

|

Feb 21, 2016 - 9:39 AM Feb 21, 2016 - 9:39 AM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

DO NOT NOT NOT use a cork gasket. use FIPG only. I dont even trust black RTV.

-------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

Feb 21, 2016 - 10:21 AM Feb 21, 2016 - 10:21 AM

|

|

|

Enthusiast      Joined Mar 11, '06 From Way South Chicago Currently Offline Reputation: 0 (0%) |

I've used permatex gray in place of FIPG with good results, it seems roughly the same when cured. FIPG is pretty rigid like permatex gray and both are excellent for oil sealing use.

-------------------- |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 23rd, 2024 - 10:41 AM |