|

Mar 15, 2011 - 10:21 AM Mar 15, 2011 - 10:21 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

Hey All,

As some of you may know, I've been doing some work for Jim, building up his Alltrac. ( Click For Alltrac Build Thread ) He came across a deal on a build, 2nd Gen 3s bottom end here on the forum,(from itchyb) and figured we could use that, with a 3rd gen head and oil system to make a nice bullet-proof bottom end to use with a nice medium sized turbo to build a great "street beast" ....~500 AWHP that comes in quick and holds out to redline. So Jim and his bro, Joe, brought me up the bottom end, and a stock 3rd gen engine set to get started with. I got the built block up on a stand, and immediately noticed a serious issue with it. The surface of the block is all pitted, and especially around the bores, like it had been shot with a Shotgun or somthing! A few pics:     What exactly caused it, I dont know, but what I do know is I definetly wouldnt trust it to seal with a metal headgasket, and I definetly wouldnt want to have the block machined that much to bring it back to flat. So, I figured to myself "Well, at least it has really nice pistons (it was supossed to have Arias pistons) and good rods (Eagle rods), so we have good stuff to work with" and continued to tear it down. When I got the oil pan off, it was more "bad" news. The pistons were not Arias, but CP pistons, which really isnt "bad", but wasnt what Jim was told was in there. A couple pics of that: (sorry for the crappy quality, the ipod cam isnt the greatest) Before taking it apart:  Eagle rods, ARP2000 Bolts:  CP Pistons:  Once I had that info, I called Jim. We talked over the options, and Jim and Joe decided that if we were gonna have to have machine work done, it might as well be on the setup they'd like to do most, which would be a stroker setup. Jim has Shannons old 5sfe bottom end, which is a 98+ block (the 98+ Celica blocks all are thicker in the waterpump corner of the block) so he said he would ship it up. Since I still have my 5s bottom end here, I told Jim that we would just use that, and he could just bring up Shannons bottom end to replace it the next time he comes up. Because MCS motorsports (the guys who built itchys bottom end) had some serious issues before they went under, I wanted to check the main bearing clearances before we did anything else, in case the crank needed any machine work. The bearings that were in it were all .25mm undersized. pic:  -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 15, 2011 - 10:55 AM Mar 15, 2011 - 10:55 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

A pic of the box i made to hold the pistons/rod combo:

I used Plastigauge, and all the mains came in ~ .051mm, spec is .023-.069 so we were good. I put the crank aside, and made another box to keep all the bearings in the correct order:  Then, I put the 5s block up on the stand, and took the crank and bearings out of that. A couple of pics of the block surface, for comparison to the other block:   Now here is where it starts to get interesting. Most guys that build "stroker" setups, use a combination of the 5s block and crank, with 3s rods and pistons, or 3s block, 5s crank ect. to create a setup with a 91mm stroke, and 87 or 87.5mm bore, depending which block they use. Jim wants to use the 3s crank, rods and 87.5mm pistons, to get a 86mm stroke, and 87.5mm bore, to create an "oversquare" setup. There are advantages to each setup, with the oversquare setup creating a very strong, rev happy motor, because there is less sidewall loading ect with the shorter stroke. A simple way to think about it is like this. Picture how the rods move side to side as the crank cycles around 360*. (think about it as a dimond shape, for arguments purpose.) With a 91mm stroke, the rods move side to side a longer distance than the 86mm stroke, which in turn puts more stress on the sides of the cylinder walls, creates more heat, ect.... Its obviously much more technical than that, but thats the basic gist of it. So, with that in mind, and the 5s and 3s main bores being the same size, I figured that we should be able to "in theory" drop all the bearings from the 3s into the 5s block, drop the 3s crank in, and all the bearing clearances should be within spec. I installed the bearings, and the crank, and put a piece of plasigauge on each main journal. For those of you who havent used it before, its pretty cool, it looks like thin fishing line. Pics of the crank installed, and the plastigauge before I installed the main caps.

-------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 15, 2011 - 11:15 AM Mar 15, 2011 - 11:15 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

I torqued the main caps down, then pulled them back off, and checked the plastigauge with the paper gauge that comes with it:

as you can see, its right about exactly the same as it was in the 3s block, so we are good to go! Now that all of that is done, we can start ordering parts, and getting the build going. this is what we have planned so far: 98 5s Block 87.5mm Weisco Pistons Eagle Rods 3s Crank ACL Race Main and Rod Bearings ARP Main and Head Studs ATS 5sgte MLS Headgasket 3rd Gen Oil System 3rd Gen Head Engle springs GSC 268* Cams W/ ATS adjustable gears RacerX Fabrication Custom Exhaust (ceramic coated )and Intake Manifolds Precision 5857, V-band 3" outlet, 4"intake w/Ceramic coated exhaust housing Tial MVS 38mm V-band Wastegate 3" Turbo back Exhaust 4" Intake of course this is all subject to change as needed as we move along..lol We're not sure if Im going to be able to get the complete Gen3 oil system, including oil cooler to work on the 5s block, but I will document the process here either way, for future refrence. A teaser pic of the Exahust manifold/Turbo combo:

-------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 15, 2011 - 7:19 PM Mar 15, 2011 - 7:19 PM

|

|

Enthusiast     Joined Apr 28, '09 From York pa Currently Offline Reputation: 3 (100%) |

that last pic is mindblowing

|

Mar 15, 2011 - 8:17 PM Mar 15, 2011 - 8:17 PM

|

|

|

Enthusiast   Joined Dec 30, '09 From Wilmington, NC Currently Offline Reputation: 1 (100%) |

Interesting move to go with the shorter stroke, but cool stuff. Looking forward to seeing the progression.

|

Mar 15, 2011 - 11:08 PM Mar 15, 2011 - 11:08 PM

|

|

|

Enthusiast   Joined Jun 5, '07 From Santa Maria Currently Offline Reputation: 1 (100%) |

Sounds like an awesome build! Can't wait to see how this turns out.

--------------------  |

Mar 15, 2011 - 11:18 PM Mar 15, 2011 - 11:18 PM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

dang those are some long runners.

please post tons of pictures on how to put the 3rd gen oil system on this block. i still havent received a good answer on my thread. good pics with the plastigauge, looks just like my build thread for Erynns 7A-FE. speaking of which, id like to have that thread stickied. -------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

Mar 16, 2011 - 9:47 AM Mar 16, 2011 - 9:47 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

dang those are some long runners. please post tons of pictures on how to put the 3rd gen oil system on this block. i still havent received a good answer on my thread. good pics with the plastigauge, looks just like my build thread for Erynns 7A-FE. speaking of which, id like to have that thread stickied. the runner length was determined by jeff, the builder, and tuned for the largest powerband with the setup jim will be running. i thought i answered your question pretty well, actually. the only "issue" that i forsee with the 3rd gen oil system is gonna be the oil cooler and the way it bolts to the housing on the block, the 5s dont use that extra mounting system, so im not sure if its gonna work on the 5s block. either way, i'll for sure be posting all the info and pics as i get to it. PM rusty with a link for your thread, he takes care of the stickys. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 16, 2011 - 7:51 PM Mar 16, 2011 - 7:51 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

I had a little time to go out to the garage today, and play with the setup some.

Like I had mentioned earlier, Jim wants to use the complete Gen3 oil system, including the oil cooler, on the 5sgte I'm building. I know guys have used the Gen3 oil setup on Gen2's before, but I've yet to see a setup where someone used a 5s block, with the Gen3 oil cooler. One of the problems is that the 3sgte oil cooler mounts to a base with a thru bolt, and the base is mounted to the block with 4 bolts. The 5s does not use a base, the oil cooler bolts right to the block using the center thru bolt. After messing with as many 5sfte variations as I did, I am used to messing with the oil coolers and how they mount, so I figured that if the 3s cooler had a rubber seal on the bottom, that was smaller than the outer diameter of the 5s oil cooler boss, than I would just have to figure out the mounting bolt situation. Here are some pics of what I did. First, a pic smaay posted of the 3rd gen oil cooler in its stock location, you can see the base it is mounted to that bolts to the block. (just like the 2nd gen 3s)  The 3rd gen oil cooler, after i removed it from the 3s block:  the bottom:  The thru bolt that bolts it in place on the 3s block:  After bending one of the lines for a little more clearance for now, I could sit the oil cooler flush against the 5s block, but the 3s thru bolt is not long enough to reach the threads....So, the 5s oil cooler thru bolt is longer, but has the mount for the oil filter. I tried that, and it works perfectly and has the appropriate holes in it to allow the oil cooler to work properly. once my tig welder arrives, I will cut off the oil filter mount, and fill that with weld. problem solved!! WOOOOOT! I just KNEW all that time spent messing with the 5sfte's would pay off someday! lol ::EDIT:: The 5s oil cooler bolt will not work. The easy solution is to use a 4th gen oil cooler, and thru bolt. (Its a bolt on deal with the 4th gen parts) The 3rd gen oil cooler, bolted to the 5sfe block using the 5sfe oil cooler bolt, that will need to be modified.  The line on the right will be cut and modified to line up with the 3rd gen water bypass lines, and the one on the left will be cut and a 6an fitting welded to it to run the coolant back around to the back of the block like the 2nd gen 3s (the 5s has a plug in the spot where the water return fitting goes on the 2nd gen.) Now its just a matter of getting the upper oil pan and windage tray off the 3rd gen block, drilling and tapping the appropriate holes for it in the 5s block, and the 3rd gen oil system on a 5s block will be complete! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 17, 2011 - 4:47 PM Mar 17, 2011 - 4:47 PM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

AAAGHHH i cant see the pics from work, stupid filters!!!!! Pressure, Jim, Dr. Tweak, have any of you guys considered not using an oil cooler at all? the 2ZZ does not use an oil cooler. i dont have any issues with my beast driving down the strip. the 7A doesnt have one either. So my big question is, is it really necessary? does the S series generate that much heat that a cooler is needed, or is it just a bling thing?

come to think of it, i took the cooler off on my All-Trac and never had a problem for the short duration i drove the car. -------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

Mar 17, 2011 - 4:59 PM Mar 17, 2011 - 4:59 PM

|

|

|

Enthusiast      Joined Aug 31, '02 From Philadelphia, PA Currently Offline Reputation: 8 (100%) |

I wonder if the lack of oil cooler on the 2zz has anything to do with the fact that it has an aluminum block.

-------------------- 15PSI - 30MPG - Megasquirt Tuned

|

Mar 17, 2011 - 5:42 PM Mar 17, 2011 - 5:42 PM

|

|

|

Enthusiast     Joined Mar 8, '09 From Westport, MA Currently Offline Reputation: 6 (100%) |

dude your knowledge of these engines blows me away, excellent work so far manny

-------------------- st205 powered ss3 coupe

|

Mar 17, 2011 - 6:48 PM Mar 17, 2011 - 6:48 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

I ran the first version of my 5sfte without an oil cooler for a short time.

It was definitely heating the oil up more... It turned black in no time. It was because of that I added the cooler back in. I can't say for sure, 100%, cause I've never monitored oil temps, but I definetly wouldn't run any of my 3s or 5s' without some form of oil cooler. besides, this is gonna be a street beast, not a track car. Sorry bout the pics, I rehosted the important oil stuff here on 6gc so it wont get lost down the road. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 21, 2011 - 6:22 PM Mar 21, 2011 - 6:22 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

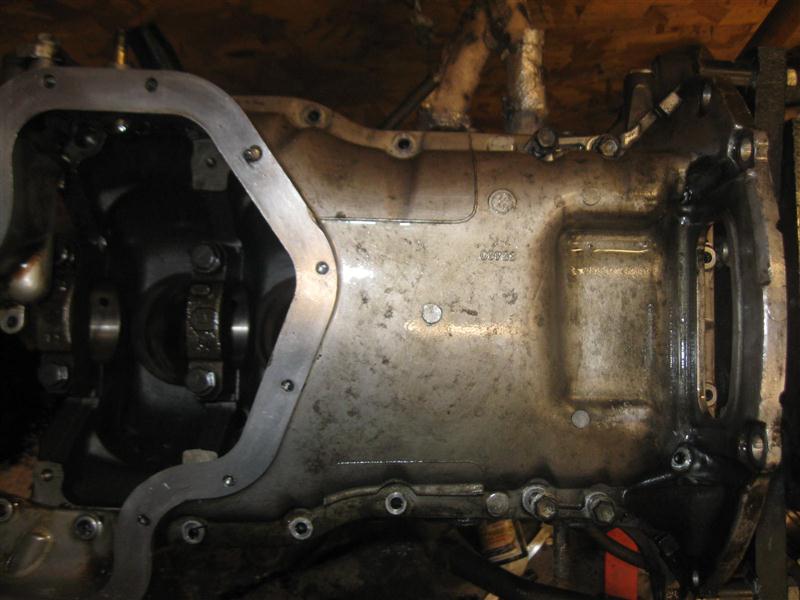

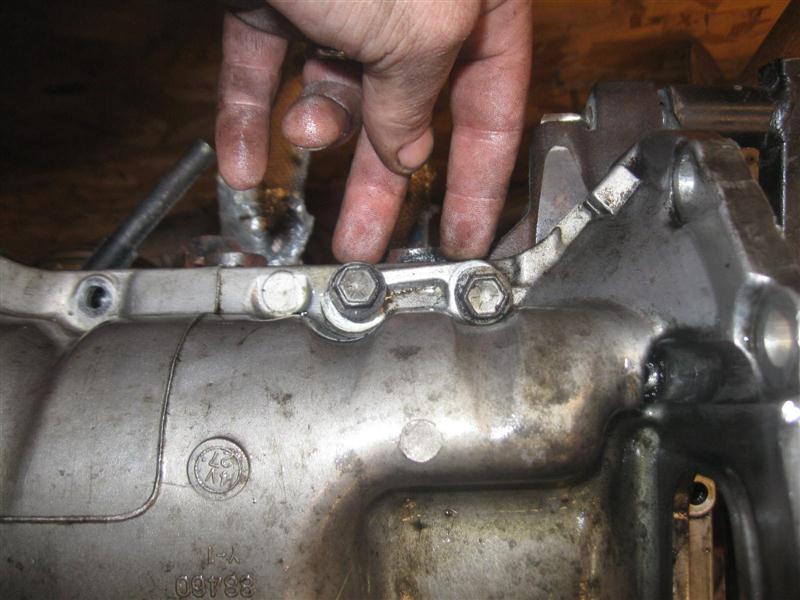

got the 3rd gen pans off the 3rd gen block, and found out what needs to be done to bolt them onto the 5s block.

here are pics. 3rd gen lower and upper oil pan, on the 3rd gen:  with the lower pan removed. the allen head bolts all have a home on the 5s block. the studs for the 2 nuts are shorter on the 5s block, so i will use the 3s ones.  here is the upper pan, layed on the 5s block. the 4 bolts you see are where i need to drill and tap for the 12mm bolts.  the bolt in the right side of the pic has a 10mm bolt hole now, i will just need to enlarge it and re-tap it. the left one will need to be started, drilled and tapped.  same here.  -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 21, 2011 - 8:31 PM Mar 21, 2011 - 8:31 PM

|

|

Enthusiast     Joined Mar 8, '08 From Orlando, Florida Currently Offline Reputation: 14 (100%) |

This thread is AWESOME.

-------------------- ◊◊◊ My F/S Thread! ◊◊◊

QUOTE (14:19:21) Daniel: That was a JDM hole in the side of the box too. There was so much JDM trapped inside that box that they couldn't contain it, so they had to put a JDM hole in the box to let the JDM out. QUOTE Ferdi says (11:29) No, it looks like a hooker put her acid vag on your hood. Acid vag = bigger problem than a few dings. |

Mar 21, 2011 - 10:47 PM Mar 21, 2011 - 10:47 PM

|

|

|

Enthusiast     Joined Oct 18, '06 From cincinnati Currently Offline Reputation: 10 (100%) |

so as far as bolting up the oil pan goes thats the difference? 12mm threads instead of 10?

huh. i'll be dipped. -------------------- proud =3sgte SWAPPED= '95 Celica ST owner [calling it the GT2 or half-trac]

309,000 miles n' .... |

Mar 22, 2011 - 7:55 AM Mar 22, 2011 - 7:55 AM

|

|

Enthusiast      Joined Feb 11, '08 From Auckland, New Zealand Currently Offline Reputation: 0 (0%) |

I think he means those 2 holes dont exist on the 5s block right? Otherwise he could just use different bolts.

With your 87.5 and 86 bore and stroke setup, does this mean the pistons will never reach the top of the deck? or would that mean you'd only get less than 2.1 liters? Also can you get the oil squirters in the 5s block or is it not necessary? That would be the main advantage of a 3s-gte block as opposed to any, right? This post has been edited by delusionz: Mar 22, 2011 - 7:56 AM -------------------- Mike W

1996 Toyota Celica ST205 GT-FOUR GT2860RS turbine, TiAL mvr44, JE 86.5φ piston, Clutchmasters FX400, APEX P-FC 269awhp / 273ft-lbs |

Mar 22, 2011 - 8:30 AM Mar 22, 2011 - 8:30 AM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

installing squirters in a block that did not have them before is not easy. it can be done if the galleys are there but it also depends on whats feeding them. for example the squirters in the 2ZZ-GE get their oil from the crankshaft. as it rotates around the main bearings it finds the hole in teh bearing and then pushes oil up into the block through the galleys to the squirters. another thing to consider that squirters cause a drop in oil pressure.

when you build a stroked 2ZZ-GE the squirters have to go. i have not had mine for something like 5 years. lots of dyno pulls and lots of miles down the track. no issues here. they are nice to have but not really necessary. thanks for the pics Pressure, now the big question is, where can i get the upper and lower oil pan. -------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

Mar 22, 2011 - 8:43 AM Mar 22, 2011 - 8:43 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

I think he means those 2 holes dont exist on the 5s block right? Otherwise he could just use different bolts. With your 87.5 and 86 bore and stroke setup, does this mean the pistons will never reach the top of the deck? or would that mean you'd only get less than 2.1 liters? Also can you get the oil squirters in the 5s block or is it not necessary? That would be the main advantage of a 3s-gte block as opposed to any, right? 2 of the 4 bolts have corresponding holes in the 5s block, but they are for 10mm bolts. I wil drill them out and tap them for the 12mm bolts. The other 2 do not have holes, but I will just drill and tap those as well. The pistons will reach just below the top of the deck thats part of the custom pistons. Total volume will be ~2.07 liters. The flat bosses are not there in the 5s block to drill and tap for the oil squirters. There are a few reasons for the 5s block, the main one being the reinforcement around the water pump corner that the pre 98 3s blocks do not have, which makes the 5s block alot less crack prone in that area. It is also said that the late blocks have a higher nickel content, which also makes them stronger. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Mar 23, 2011 - 12:49 AM Mar 23, 2011 - 12:49 AM

|

|

|

Enthusiast     Joined Oct 18, '06 From cincinnati Currently Offline Reputation: 10 (100%) |

you and your great wealth of knowledge sir. i continue to be impressed.

-------------------- proud =3sgte SWAPPED= '95 Celica ST owner [calling it the GT2 or half-trac]

309,000 miles n' .... |

|

1 User(s) are reading this topic (1 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: November 22nd, 2024 - 5:59 PM |