|

Oct 30, 2010 - 10:28 PM Oct 30, 2010 - 10:28 PM

|

|

|

Enthusiast     Joined Mar 8, '09 From Westport, MA Currently Offline Reputation: 6 (100%) |

installed the symtech map clamp earlier this week...man, this car HAULS @ 18-19psi. still dont have the WI installed, but even at 18+psi, i havent felt it hesitate once. WOOT for the 3rd gen!! Niiiccccceee! .. how much that run you? (the clamp) -------------------- st205 powered ss3 coupe

|

Oct 31, 2010 - 8:05 AM Oct 31, 2010 - 8:05 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

nice, could have used that info 2 weeks ago. cam the map clamp was ~50$. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Oct 31, 2010 - 11:35 AM Oct 31, 2010 - 11:35 AM

|

|

|

Enthusiast     Joined Mar 8, '09 From Westport, MA Currently Offline Reputation: 6 (100%) |

-------------------- st205 powered ss3 coupe

|

Oct 31, 2010 - 6:11 PM Oct 31, 2010 - 6:11 PM

|

|

|

Enthusiast   Joined Jul 23, '08 From Hawaii Currently Offline Reputation: 6 (100%) |

they are even located in HI! maybe 5min from work great find! |

Nov 2, 2010 - 3:56 PM Nov 2, 2010 - 3:56 PM

|

|

|

Enthusiast    Joined Sep 22, '08 From Bergenfield Currently Offline Reputation: 5 (78%) |

For those that buy the Symtech map clamp, once you have it dialed in...take some clear nail polish and tab thy "adjusting screw" to lock it into place. You dont want the vibration from driving to move your set adjustment...especially to lower voltage. If the map clamp were to vibrate to say 16psi or below, your injectors would not go full duty after 4000rpms, and you would run terribly lean (because obviously if you have the map clamp you are running 20+psi...hence the need for one.) I say nail polish because it is easily removable with nail polish remover in case you were ever to have a need to readjust your map clamp, and the clear keeps it looking clean.

--------------------

|

Nov 3, 2010 - 12:19 PM Nov 3, 2010 - 12:19 PM

|

|

|

Enthusiast     Joined Oct 20, '08 From Seattle, WA Currently Offline Reputation: 5 (100%) |

For those that buy the Symtech map clamp, once you have it dialed in...take some clear nail polish and tab thy "adjusting screw" to lock it into place. You dont want the vibration from driving to move your set adjustment...especially to lower voltage. If the map clamp were to vibrate to say 16psi or below, your injectors would not go full duty after 4000rpms, and you would run terribly lean (because obviously if you have the map clamp you are running 20+psi...hence the need for one.) I say nail polish because it is easily removable with nail polish remover in case you were ever to have a need to readjust your map clamp, and the clear keeps it looking clean. Wow, that's a good idea, never really thought or heard of this method before. -------------------- 2006 BMW 330i - 6 Speed - Dinan Stage 1

2014 Toyota Rav4 XLE |

Nov 3, 2010 - 2:04 PM Nov 3, 2010 - 2:04 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

For those that buy the Symtech map clamp, once you have it dialed in...take some clear nail polish and tab thy "adjusting screw" to lock it into place. You dont want the vibration from driving to move your set adjustment...especially to lower voltage. If the map clamp were to vibrate to say 16psi or below, your injectors would not go full duty after 4000rpms, and you would run terribly lean (because obviously if you have the map clamp you are running 20+psi...hence the need for one.) I say nail polish because it is easily removable with nail polish remover in case you were ever to have a need to readjust your map clamp, and the clear keeps it looking clean. good stuff, jimbo, i was planning on using a dab of hot glue. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Nov 3, 2010 - 10:44 PM Nov 3, 2010 - 10:44 PM

|

|

|

Enthusiast     Joined Mar 8, '09 From Westport, MA Currently Offline Reputation: 6 (100%) |

For those that buy the Symtech map clamp, once you have it dialed in...take some clear nail polish and tab thy "adjusting screw" to lock it into place. You dont want the vibration from driving to move your set adjustment...especially to lower voltage. If the map clamp were to vibrate to say 16psi or below, your injectors would not go full duty after 4000rpms, and you would run terribly lean (because obviously if you have the map clamp you are running 20+psi...hence the need for one.) I say nail polish because it is easily removable with nail polish remover in case you were ever to have a need to readjust your map clamp, and the clear keeps it looking clean. good stuff, jimbo, i was planning on using a dab of hot glue. both ideas, very good, good looks guys! lol -------------------- st205 powered ss3 coupe

|

Nov 5, 2010 - 4:41 PM Nov 5, 2010 - 4:41 PM

|

|

|

Enthusiast      Joined Feb 1, '05 From Charlotte NC Currently Offline Reputation: 14 (100%) |

a map clamp had been mentioned to me before, but iirc someone told me my management had one already? im a bit confused, unless i overlooked it earlier can someone explain the map clamp to me? i remember reading about it but needed confirmation... thinking about adding this to the setup...

-------------------- |

Nov 5, 2010 - 5:57 PM Nov 5, 2010 - 5:57 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

a map clamp had been mentioned to me before, but iirc someone told me my management had one already? im a bit confused, unless i overlooked it earlier can someone explain the map clamp to me? i remember reading about it but needed confirmation... thinking about adding this to the setup... lol i just FB you about it..lol i would check the documentation on the blue, im not sure if it can do it, but the EMU can do the map clamp. in very basic terms, the map sensor sends a voltage to the ECU that lets it know how much pressure is in the manifold, and the ECU uses that and the inputs from the other sensors to determine how much fuel/timing to use. when you run more boost than the ecu allows, the voltage from the map sensor goes above what the ecu says is "normal" and intiates fuel cut. with an active clamp like we have to use, allows the ecu to see normal voltage below the boost cut threshold, and once we set the voltage on the clamp, dont allow the ecu to see above that point. the idea is to lock the voltage just below fuel cut, where the ecu is thinking there is just about 18 or so psi, and dumping all the fuel it can in, that way, you can run more than 18psi, since the 3s ecus are normally tuned very rich up top. IIRC jim ran it up to 24 or so PSI and still wasnt running lean, but thats somthing you do slowly on a dyno with a wideband. (turning the boost up a little at a time and watching AFR's as you go) HTH bro! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Nov 5, 2010 - 6:28 PM Nov 5, 2010 - 6:28 PM

|

|

Enthusiast     Joined Apr 28, '09 From York pa Currently Offline Reputation: 3 (100%) |

dat makes thing so much clearer now thanks wat i read online was giberish lol

|

Nov 6, 2010 - 8:53 PM Nov 6, 2010 - 8:53 PM

|

|

|

Enthusiast      Joined Feb 1, '05 From Charlotte NC Currently Offline Reputation: 14 (100%) |

dat makes thing so much clearer now thanks wat i read online was giberish lol x2 everytime i tried to read up on it, there was either an E=mc2 Explanation (im a counselor not a physicist or engineer thanks manny!!! so looks like i'll be map clamping! will also see if the blue has one. -------------------- |

Nov 7, 2010 - 8:47 AM Nov 7, 2010 - 8:47 AM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

yea its technicly boost cut. the way the ecu does it is by cutting the fuel, which is why some call it fuel cut.

i would imagine the blue should have the map clamp feature. -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Nov 7, 2010 - 12:05 PM Nov 7, 2010 - 12:05 PM

|

|

|

Enthusiast  Joined Dec 14, '08 From La La Land.. Currently Offline Reputation: 6 (100%) |

wow.. a magician at work! so far so good!

-------------------- -----------

Stay Conscious and Aware - Do not decide who to trust, decide which ideas to trust. |

Feb 1, 2014 - 8:29 PM Feb 1, 2014 - 8:29 PM

|

|

|

Moderator      Joined Oct 1, '02 From fall river, ma Currently Offline Reputation: 13 (100%) |

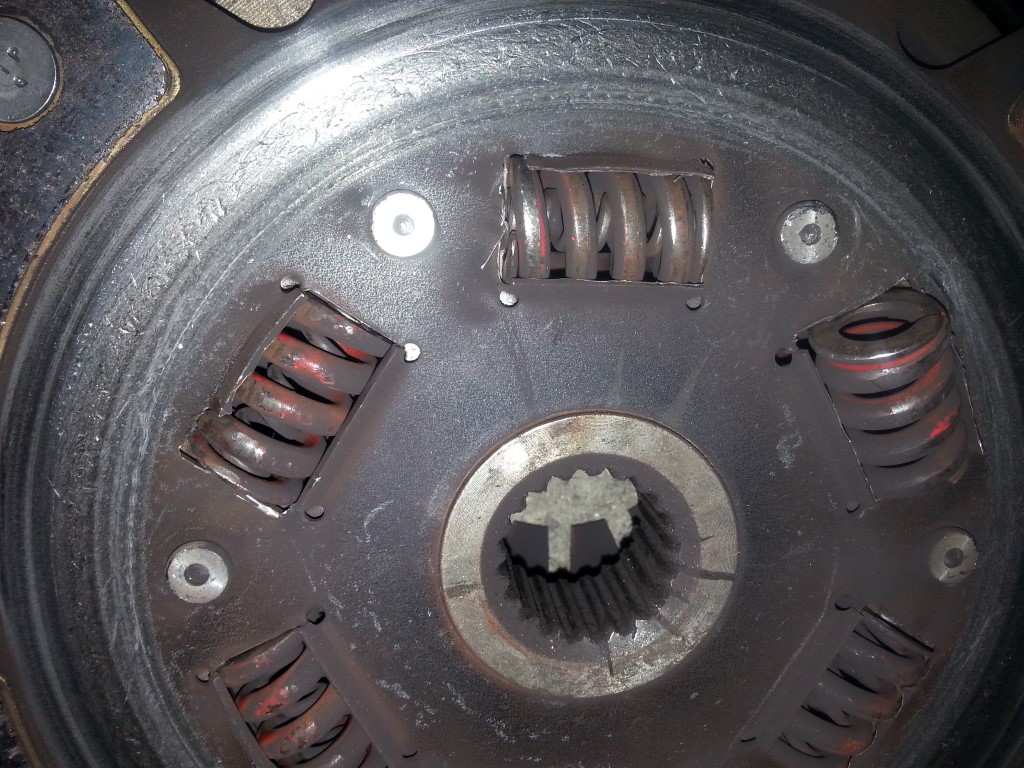

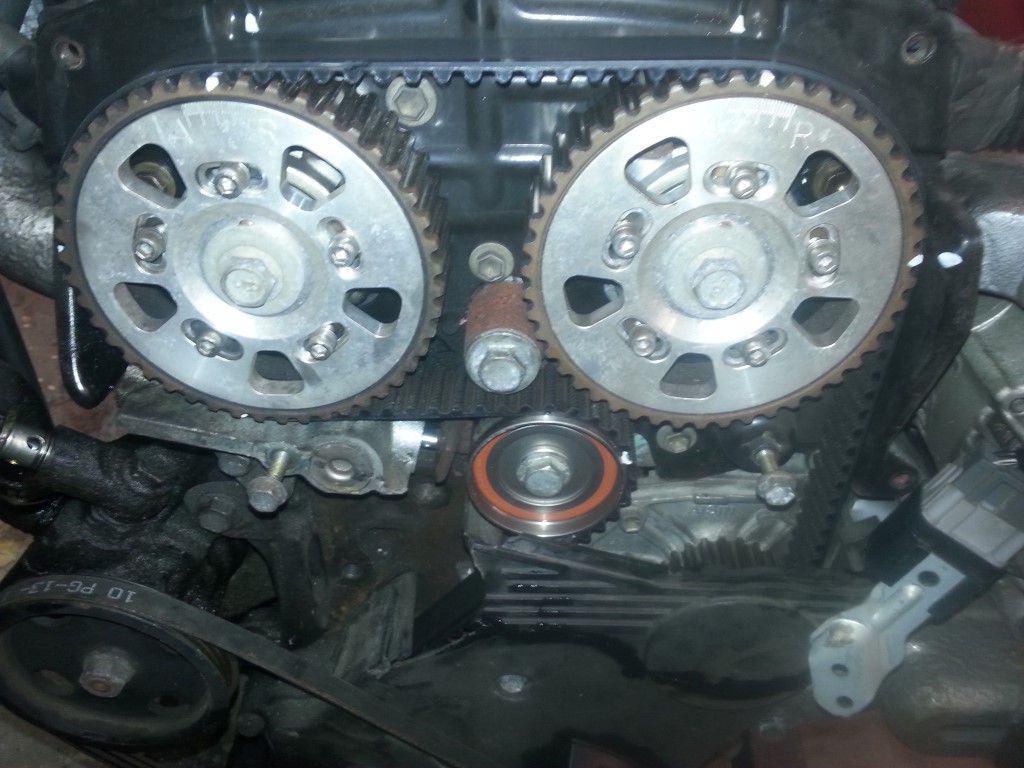

Well, its been almost 4 years since we swapped, and other than the idler bearing issue I posted about back in 2010, the car has been an absolute pleasure to drive, the engine has performed flawlessly, up until several weeks ago..

Jenn let me know that she noticed the idle was off, that it started idling really high. so, I went ahead and checked it out for her. Once I opened the hood, I instantly noticed that the water injection nozzle was once again broken off the back of the intake manifold, like had happen back in 2010. This time, the threads are locked into the intake manifold, and in order to remove them, I was going to have to remove it. So, instead of doing that, I just blocked the hole with a cap I had laying around, and used some FIPG to ensure a tight seal around it. It worked like a champ, and the idle was back to normal. Around that same time, we also started having issues with the clutch, intermittently not wanting to go into gear, especially when it was cold. I thought maybe it was somthing simple, like old fluid or somthing, but had an odd feeling that it was somthing more, like maybe a spring popping out or somthing. So, I went ahead and changed out the fluid, hoping for the best, but to no avail. it still had that once in a while issue of not wanting to go into gear. Fast forward a week or 2, and Jenn lets me know that the car is now making a "howling" noise, somewhat similar to the noise it made when the idler bearing went bad. So, once again, I pulling the car in the garage and started looking things over. Since I dont run an upper timing belt cover, I was able to get in there with my mechanics stethascope, and listening thru that, it sounded like it was possibly the #2 idler bearing. So, I jacked the car up, and prepared to pull the lower timing cover, and what I found was interesting to say the least! Back when I did the water injection nozzle thingy, I noticed that the motor seemed tilted to the passanger side, but just ignored it. That was a bad idea. The passanger side bracket, that connects the engine mount to the engine, had sheared the bolts that hold it in place, causing the motor to tilt over and actually rest on the tensioner/idler bearing!! Those of you who are friends with me on facebook may have seen the pic I posted about it, but here it is for those of you who havent seen it.  Because of how little room there is to work in there, I decided to pull the motor out to make it easier to get those broken bolts out. So, Dustin and Steff came by, and gave me a hand pulling the motor. Once it was out, it was easy to tell exactly what was happening. Because of the mount bolts shearing, the bracket was actually pressing against the idler bearing, which was causeing the noise we were hearing. Another side effect of the bolts shearing was that it basicly killed my front and rear mounts, so I went ahead and ordered kirkosorus motor mount inserts. While the motor was out, I decided to pull the transmission off, and check the status of the clutch, since I was a little nervous about the intermittent issues we had been having with it. Its a good thing I did. As expected, the competition clutch disk was starting to spit a spring out. Like I had posted way back when I started this thread, the clutch I used when I did this swap was the same competition clutch that I used back when I had the 5sfte. When I swapped, I wanna say I noted that I was worried about how the springs looked then..fast forward 3+ years, but only around 10k actual driving miles total between the 5s and 3rd gen, and heres what happen:   you can see how the spring housings are all worn out and about to spit them all out..shizz happens I guess. Now, I've honestly always hated how heavy this clutch was. Between the super heavy pressure plate, the harsh 6 puck disk, and the LW fidanza flywheel, the engagement was horribly harsh and sharp, the pedal feel was super heavy, it just made the car a real chore to drive, and absolutly sucked driving in traffic. Over the past few years, Jenn and I have been driving the Celica less and less, Jenns work is litterally only a few blocks from our house, and most of her daily driving is just in the city, grocery getter type stuff. Once in a while I will drive the car to work, around 35 miles round trip, and even then its 95% highway driving, and not like we're racing the car at all. Its been years since I've been to the track, and we litterally almost never launch the car from a stop. That said, I really wanted to go to a more OEM style clutch. So, I decided to try and experiment, and see if I can get a OEM clutch setup to work on the 3rd gen swap. Now, before I go any further, I really want to stress that I do not recommend this setup to the average 3sgte swap guy, for several reasons. first, this clutch probably wont hold much more than what the stock engine can put out with just bolt ons like the average guy does. It more than likely wont hold up to hard launches, or track days either. But, since my budget was very little, and I had some spare parts laying around, I decided to try this setup. I have several stock, used 3rd gen 3sgte clutch setups that I have aquired over the years while doing swaps for people (and myself), so I decided to use a used stock 3rd gen pressure plate, and I had steff get me a new 5sfe (S54) clutch disk. Now, before anyone freaks out and tells me it wont hold, remember that the pressure plate is what provides the holding power, not the disk, the disk only controls the amount of slip and bite, here are some pics to show some of the diffrences between the stock 3rd gen disk, and a stock 5s(S54 disk). first, since comp originally sent me a 5s disk, instead of the hybrid 3s disk w/ 5s spline, like I wanted, the wear point on the fidanza pressure plate is exactly the same size as a 5s disk, which worked out well for me. here are pics of both a 5s disk, and a 3s disk. 5s:  3s  2 things. the 3s disk is about 10mm larger, which will in theory provide more clamping area, which in turn will create more holding power. but my retort is that 5s disks have been holding 3sgte power for years, both in my car, and lots of other guys who have thought they got hybrid 3s/5s disks that are just sent 5s disks. also, because of the larger clamping area, the metal stamped steel part that holds the disk to the hub is smaller on a 3s disk compared to a 5s disk. if anything, this is where I think a problem may arize with the disk, and probably a point of failure if I were to launch hard repeadtely or with track style driving. here is a pic of the 5s disk on the fidanza flywheel, right before I installed the pressure plate.  pressure plate installed  So with that taken care of, I turned my attention to the idler bearing that the mount bracket had been pressing against. First, I was super lucky, because 1 of the 3 bolts I was able to turn out by hand, and the other 2, I just cut a very small groove into the bolts with a dremel tool, and was able to just back them out with a screwdriver. heres a pic of the bolts, and the bolt holes after I was done.   My last few posts in this thread are about changing that bearing a few years ago, and culpable04 posted that I could have gotten just the bearing instead of the whole assembely like I had done. So, I took a good pic of the bearing, and put the part # into a google search. That took me to amazon, where I was able to purchase just the bearing, for 12$+ shipping! Big diffrence compared to the 104$ I paid a few years ago for the bearing and brakcet from toyota. Here are some pics of that. first a side by side of the OEM bearing VS the OEM replacement I ordered. same brand, same stamps, same everything.  the packaging for the bearing (use those PT#'s to get them.)  the bracket it attaches to:  once I replaced the bearing, I buttoned it all back up.  Dustin and steff came by, and gave me a hand putting the motor back in, we buttoned it all back up, and it fired right back up, first try. The clutch feels awesome, just like a stock clutch should feel. I am just breaking it in, and not like I'm going out trying to wreck it in the first week, so no hard launches, but it does hold boost just fine once its in gear and going just fine. I will report back once its fully broken in a driving for a while, but the biggest improvments are that the clutch pedal now engaged right about the middle of the pedal travel, like it should VS 2" off the floor like it was with the comp, and the engagement is so nice and smooth VS the harshness of the comp clutch. We'll see how it holds up over time, but for now, its just great. time will tell. enjoy! -------------------- Former Team 5SFTE pro member ;)

13.6@108MPH, 5SFTE Powered |

Feb 1, 2014 - 11:51 PM Feb 1, 2014 - 11:51 PM

|

|

|

Enthusiast      Joined Dec 8, '03 From Lancaster CA Currently Offline Reputation: 6 (100%) |

awesome update!!!!

-------------------- 2001 Celica GT-S Turbo

1997 Supra TT 6speed 1997 Celica 3MZ/1MZ swap 1990 Celica All-Trac |

Feb 2, 2014 - 6:41 PM Feb 2, 2014 - 6:41 PM

|

|

|

Enthusiast      Joined Jun 18, '09 From Orlando Currently Offline Reputation: 8 (100%) |

Excellent stuff.

-------------------- '97 ST \ Eibach \ KYB \ Kenwood \ Alpine \ Cusco \ OEM+ [sold 10/18]

'93 MX-5 LE |

|

2 User(s) are reading this topic (2 Guests and 0 Anonymous Users)

0 Members:

| Lo-Fi Version | Time is now: February 18th, 2025 - 5:54 AM |